The global rubber sheet market has witnessed significant growth, reaching a valuation of approximately $5.5 billion in 2022, and it is projected to expand at a CAGR of 4.5% through 2030, driven by increasing demand across various industries such as automotive, construction, and healthcare. China stands out as a key player in this domain, noted for its advanced manufacturing capabilities and extensive export reach, with over 25% of the global rubber sheet supply originating from Chinese manufacturers. These companies leverage innovative technologies and adhere to international quality standards, which not only enhances their competitive edge but also meets the diverse needs of clients worldwide. The combination of high-quality production and strategic global presence positions Chinese rubber sheets at the forefront of the market, making them indispensable in securing a foothold in various industrial applications.

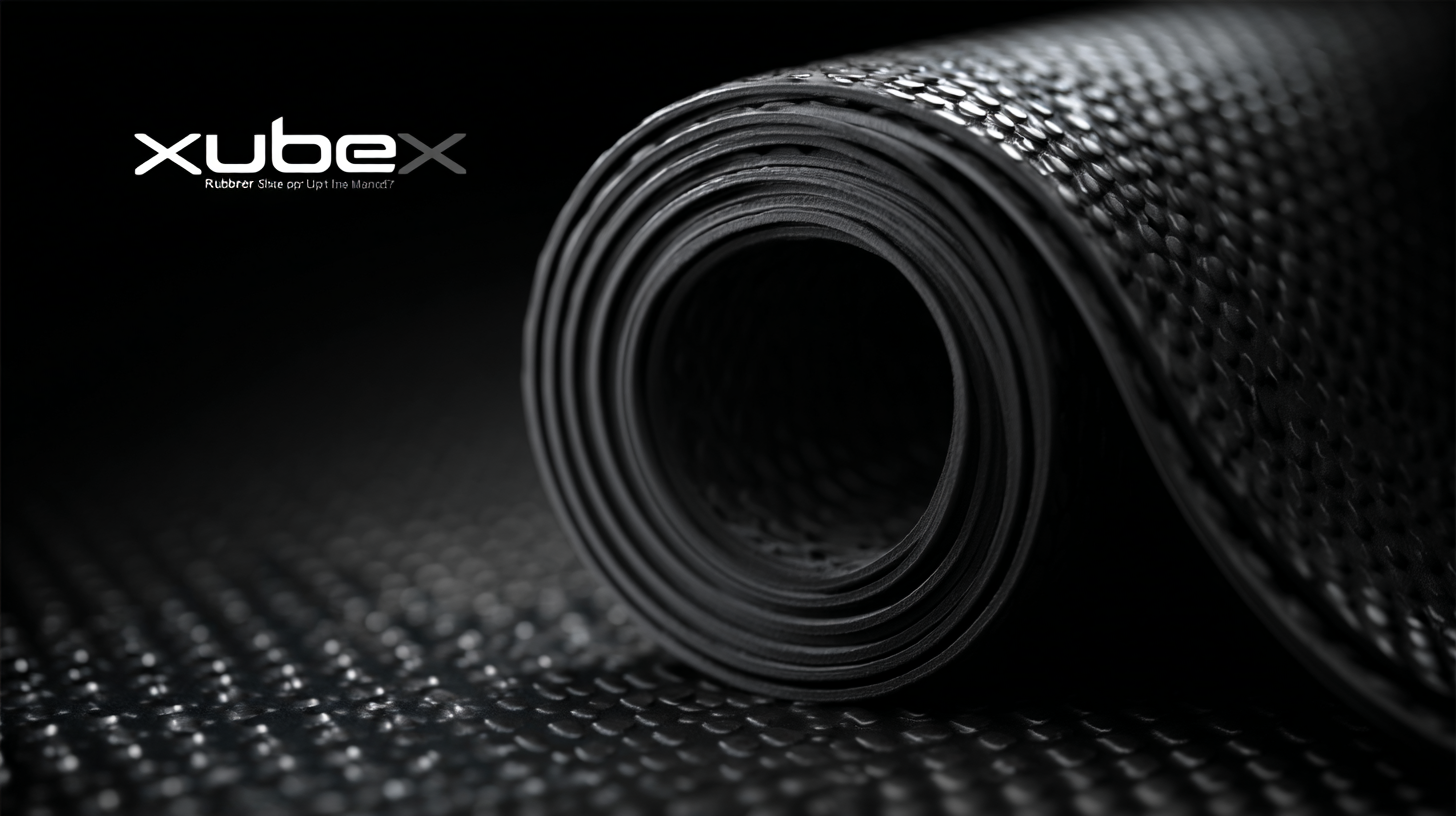

In the global market, high-quality rubber sheets are distinguished by several key characteristics that cater to diverse industrial needs. First and foremost, durability is essential. The best rubber sheets are designed to withstand extreme environmental conditions, including temperature fluctuations and exposure to chemicals. This resilience ensures they maintain their functional integrity over time, making them a reliable choice for industries such as automotive and construction. Additionally, an effective rubber sheet should have excellent elasticity, offering flexibility while retaining its shape under pressure, which is crucial for applications requiring dynamic movement.

Another significant characteristic is surface texture. High-quality rubber sheets often feature specific textures that enhance grip and prevent slippage, contributing to safety in various applications. Furthermore, eco-friendliness has become a crucial factor as industries increasingly seek sustainable materials. The best rubber sheets utilize recycled materials and manufacturing processes that limit environmental impact, appealing to forward-thinking companies committed to sustainability. As global markets evolve, these characteristics not only set premium rubber sheets apart but also align with the growing demand for innovative and responsible material solutions.

When searching for reliable rubber sheet manufacturers, it is crucial to consider the

essential certifications and standards that reflect their

commitment to quality and safety. Certifications such as

ISO 9001 for quality management and ISO 14001 for

environmental management indicate that a manufacturer adheres to

internationally recognized principles in production practices. Moreover, compliance with

industry-specific standards, such as ASTM or FDA regulations,

ensures that the rubber sheets meet the required safety and performance benchmarks.

Tips for selecting a manufacturer include verifying their certification credentials and

assessing their production processes through facility visits or audits. Ensure that the

manufacturer not only produces rubber sheets that comply with necessary standards but also

actively engages in continuous improvement practices. This

commitment to quality often translates into superior product performance

and reliability.

Furthermore, exploring customer testimonials and case studies can provide insight into the

manufacturer’s reputation in the marketplace. Companies with a proven track record of

delivering certified high-quality products are more likely to meet your specific needs while

maintaining compliance with essential industry standards.

Prioritizing these elements will help you make informed decisions when choosing a rubber sheet manufacturer.

When evaluating rubber sheets in the global market, the reputation of manufacturers plays a crucial role in determining product quality and reliability. A reputable manufacturer typically has a solid track record of producing durable and high-performance rubber products. Their commitment to quality assurance often begins with stringent sourcing of raw materials and ends with rigorous testing before the product reaches the customer. Manufacturers that are well-regarded often invest in advanced production technologies and practices, ensuring compliance with international standards that meet or exceed customer expectations.

Customer feedback is another vital component in assessing the effectiveness of rubber supply chains. Reviews and testimonials provide insight into the performance of rubber sheets in real-world applications, helping potential buyers make informed decisions. By analyzing both positive and negative feedback, customers can ascertain the strengths and weaknesses of specific products, which in turn allows them to choose the best rubber sheets for their specific needs. Thus, integrating manufacturer reputation and customer feedback creates a comprehensive approach for identifying standout rubber sheets in a competitive global market.

In today's global market, eco-friendly production practices play a crucial role in determining the quality and appeal of rubber sheets. The shift towards sustainable practices not only serves the environment but also enhances the durability and performance of the final product. When manufacturers prioritize using renewable resources and reducing waste, they inevitably improve the overall quality of rubber sheets.

Tip: When selecting rubber sheets, look for products made from sustainably sourced materials. Certifications from recognized environmental organizations can serve as a reliable indicator of a product’s ecological integrity.

Moreover, eco-friendly production processes often involve innovative technologies that minimize harmful chemicals and energy consumption. This not only lowers the environmental impact but also results in safer, more resilient rubber sheets. As customers become increasingly aware of their choices, they are more likely to favor brands committed to sustainability.

Tip: Always check the manufacturing processes utilized by the brand. Companies that openly disclose their eco-friendly practices are usually more dedicated to maintaining high standards of quality and safety in their products.

In the competitive global market for rubber sheets, innovative technologies play a pivotal role in distinguishing the best products. Advanced manufacturing processes, such as automated mixing and precision molding, enhance the efficiency and consistency of rubber sheets. These technologies not only reduce production time but also minimize material waste, leading to a more sustainable approach.

Tips for manufacturers looking to implement these technologies include investing in high-quality machinery and training personnel on the latest techniques. Regular maintenance of equipment is crucial to ensure optimal performance and longevity. Additionally, exploring new materials that enhance durability and flexibility can set a product apart in a saturated market.

Adopting digital monitoring tools can also offer real-time insights into production processes, helping identify bottlenecks and optimize workflows. By leveraging data analytics, manufacturers can fine-tune their operations for improved quality control, ultimately leading to a superior product that meets or exceeds global standards.

| Dimension | Traditional Method | Innovative Technology | Impact on Quality | Market Demand |

|---|---|---|---|---|

| Material Composition | Natural Rubber | Recycled Rubber Blends | Higher Durability | Increasing |

| Manufacturing Process | Calendering | 3D Printing | Reduced Waste | Fluctuating |

| Thickness Options | Limited | Customizable | Tailored to Demand | Rising |

| Durability Factor | Moderate | High Resistance | Extended Lifespan | Growing |

| Environmental Impact | Moderate | Low | Eco-Friendly | Increasing |