In today's competitive manufacturing landscape, the importance of selecting high-quality suppliers for gasket material cannot be overstated. According to a recent market report by Grand View Research, the global gasket market is expected to reach $14.31 billion by 2025, driven by the increasing demand for efficient sealing solutions across various industries, including automotive and aerospace. Sourcing superior gasket materials not only enhances product performance but also significantly reduces operational risks associated with equipment failures and leaks. Therefore, manufacturers must be judicious in their selection process, assessing both the technical specifications and the reliability of potential suppliers. This guide will arm you with the critical knowledge and strategies needed to identify and collaborate with the best suppliers for high-quality gasket materials, ensuring your products meet the highest industry standards while optimizing supply chain efficiency.

In today's competitive manufacturing landscape, the importance of selecting high-quality suppliers for gasket material cannot be overstated. According to a recent market report by Grand View Research, the global gasket market is expected to reach $14.31 billion by 2025, driven by the increasing demand for efficient sealing solutions across various industries, including automotive and aerospace. Sourcing superior gasket materials not only enhances product performance but also significantly reduces operational risks associated with equipment failures and leaks. Therefore, manufacturers must be judicious in their selection process, assessing both the technical specifications and the reliability of potential suppliers. This guide will arm you with the critical knowledge and strategies needed to identify and collaborate with the best suppliers for high-quality gasket materials, ensuring your products meet the highest industry standards while optimizing supply chain efficiency.

When searching for high-quality gasket material suppliers, it’s essential to identify the key characteristics that distinguish the best from the rest. First and foremost, look for suppliers with a proven track record in the industry. A reputable supplier will have positive customer testimonials and case studies that showcase their ability to deliver high-performance gasket materials consistently. Additionally, consider suppliers that have industry certifications, which can ensure that their products meet stringent quality standards.

Tips: Always inquire about the supplier's manufacturing processes and material sourcing. This will give you insight into their commitment to quality and sustainability. Another critical characteristic is the supplier's responsiveness to customer inquiries and their capability to provide technical support, ensuring that you have the necessary guidance during the selection process.

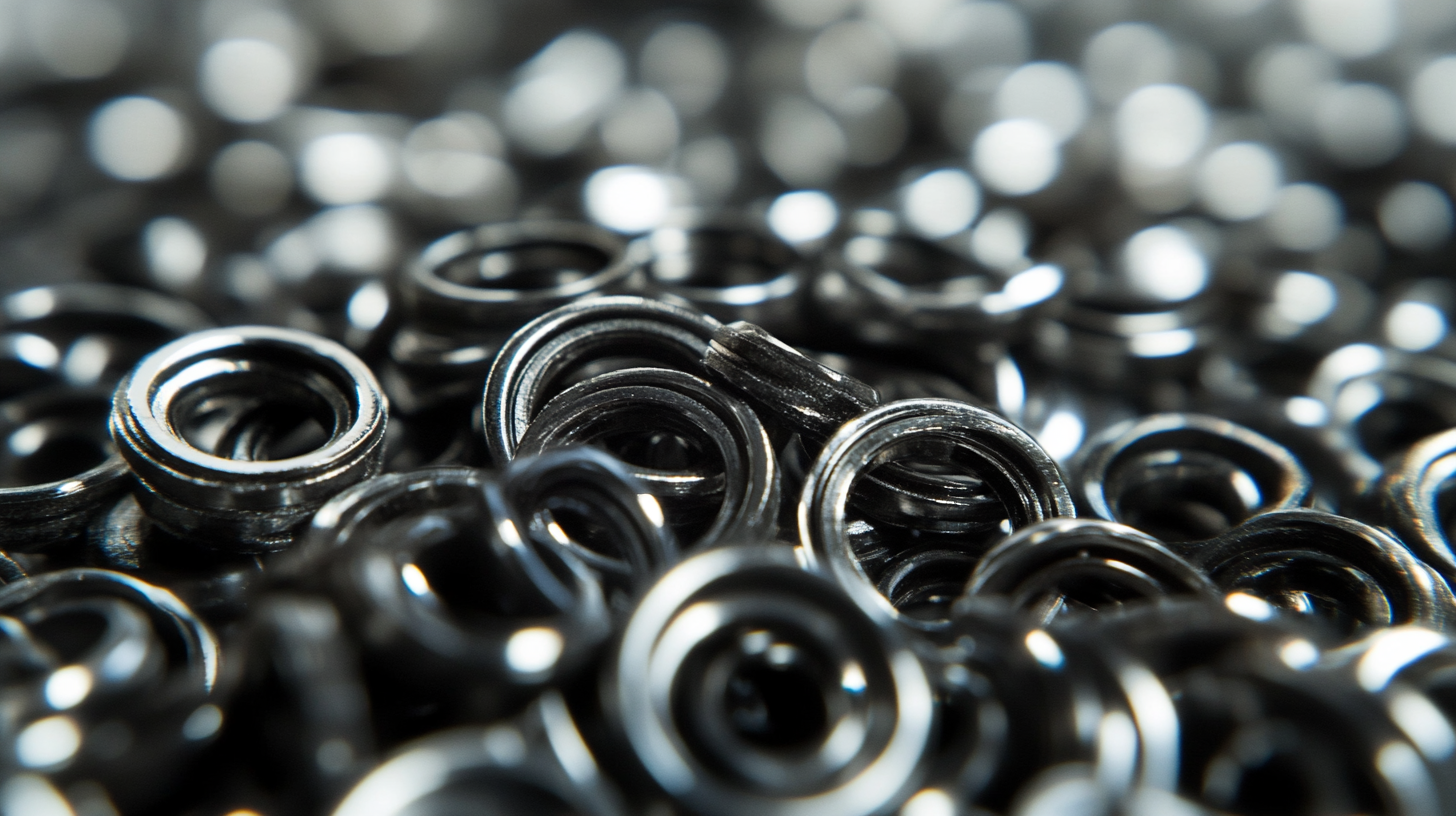

Additionally, high-quality gasket material suppliers often offer a wide range of products tailored to different applications. It’s beneficial to work with suppliers that can customize their offerings based on your specific needs. Check their inventory for diversity in material types, such as rubber, silicone, or metal, which can significantly impact your operational efficiency. This variety can save you time and money while ensuring that you choose the best material for your applications.

When evaluating suppliers for gasket materials, it’s crucial to consider their certifications and adherence to industry standards. Certifications serve as a testament to a supplier's commitment to quality and sustainability. For example, suppliers that hold relevant certifications demonstrate compliance with international regulations and best practices in manufacturing processes. This is particularly important in the industrial gaskets market, which is projected to reach USD 16.84 billion by 2030. Understanding these certifications can help businesses ensure they are partnering with reliable suppliers who prioritize quality.

**Tips:** When assessing potential suppliers, request copies of their certifications and verify their validity through industry bodies. Additionally, consider suppliers that actively participate in sustainability initiatives, as this can indicate a forward-thinking approach and responsible sourcing practices. Lastly, analyze their prior work, seeking case studies or references from past clients to ensure their products meet your required standards.

In addition to certifications, consider the supplier's experience and reputation within the industry. Suppliers that have consistently met or exceeded industry standards demonstrate reliability and commitment to continuous improvement. Their experience can offer insights into the latest materials and innovations, giving your business a competitive edge in product quality and performance.

Conducting effective supplier audits and assessments is crucial for securing high-quality gasket materials. First, it's essential to establish a structured audit framework that focuses on key performance indicators such as quality control processes, compliance with industry standards, and delivery timelines. Regular audits not only verify that suppliers meet your specifications but also help uncover areas for improvement in their operations. For instance, assessing their manufacturing processes, equipment condition, and staff qualifications can provide insights into their potential to deliver consistently high-quality products.

Moreover, involving cross-functional teams during the audit process can enhance the comprehensiveness of your assessments. Engaging representatives from procurement, engineering, and quality assurance ensures that different perspectives contribute to evaluating supplier capabilities and performance. Additionally, utilizing checklists tailored to the specific requirements of gasket materials can lead to more objective evaluations. By prioritizing open communication during these audits and fostering partnerships with suppliers, organizations can both strengthen their supply chains and ensure they are using the best materials available in their products.

Effective communication and relationship management are crucial components when it comes to sourcing high-quality suppliers for gasket material. Establishing a solid rapport with suppliers goes beyond mere transactions; it involves understanding their capabilities, processes, and challenges. Regular dialogue ensures that both parties are aligned on expectations, quality standards, and delivery schedules. This ongoing communication fosters transparency, enabling businesses to promptly address any issues that might arise during the production or delivery phases.

Moreover, investing time in building strong relationships can lead to enhanced collaboration and innovation. When suppliers feel valued and engaged, they are more likely to go the extra mile in terms of product quality and service. This partnership environment not only helps in negotiating better terms but also encourages suppliers to proactively suggest improvements or alternatives that can benefit your operations. Ultimately, a well-managed relationship with your suppliers is key to ensuring a steady supply of top-notch gasket materials, which can significantly impact your business's overall success.

In today's fast-paced manufacturing landscape, leveraging technology for efficient supplier sourcing and management has become paramount. Digital platforms and tools can significantly streamline the process of finding high-quality suppliers for gasket materials. By utilizing advanced search algorithms and data analytics, businesses can quickly identify suppliers that meet their specific criteria. This reduces the time spent on traditional sourcing methods and enables companies to make informed decisions based on real-time data and supplier performance metrics.

Moreover, incorporating supplier management software can enhance collaboration and communication between manufacturers and suppliers. Features such as dashboards for tracking order statuses, performance reviews, and feedback mechanisms ensure that both parties remain aligned throughout the supply chain. With these technological advancements, businesses can foster stronger relationships with their suppliers, ultimately leading to improved product quality and a more efficient procurement process. Embracing technology not only aids in sourcing the best gasket materials but also positions companies to adapt and thrive in an increasingly competitive market.

| Supplier Location | Gasket Material Type | Minimum Order Quantity | Lead Time (Days) | Quality Certification |

|---|---|---|---|---|

| North America | Rubber | 100 pcs | 14 | ISO 9001 |

| Europe | Silicone | 50 pcs | 10 | ISO 14001 |

| Asia | Compressed Fibre | 200 pcs | 21 | AS9100 |

| South America | PTFE | 150 pcs | 30 | ISO 9001 |