In the pursuit of high-performance sealing solutions, PTFE gasket material has emerged as a preferred choice across various industries due to its remarkable properties such as chemical resistance, thermal stability, and low friction.

As demand grows for reliable and durable sealing components, sourcing from a dependable manufacturing factory becomes crucial.

This blog will delve into the finest strategies for selecting premium PTFE gasket material from leading manufacturers in China.

We will explore key factors such as quality assurance, production techniques, and the importance of understanding specific application requirements that ensure optimal performance and longevity of the gaskets.

By understanding these strategies, businesses can make informed decisions and partner with manufacturers that consistently deliver excellence in PTFE gasket material production.

In the pursuit of high-performance sealing solutions, PTFE gasket material has emerged as a preferred choice across various industries due to its remarkable properties such as chemical resistance, thermal stability, and low friction.

As demand grows for reliable and durable sealing components, sourcing from a dependable manufacturing factory becomes crucial.

This blog will delve into the finest strategies for selecting premium PTFE gasket material from leading manufacturers in China.

We will explore key factors such as quality assurance, production techniques, and the importance of understanding specific application requirements that ensure optimal performance and longevity of the gaskets.

By understanding these strategies, businesses can make informed decisions and partner with manufacturers that consistently deliver excellence in PTFE gasket material production.

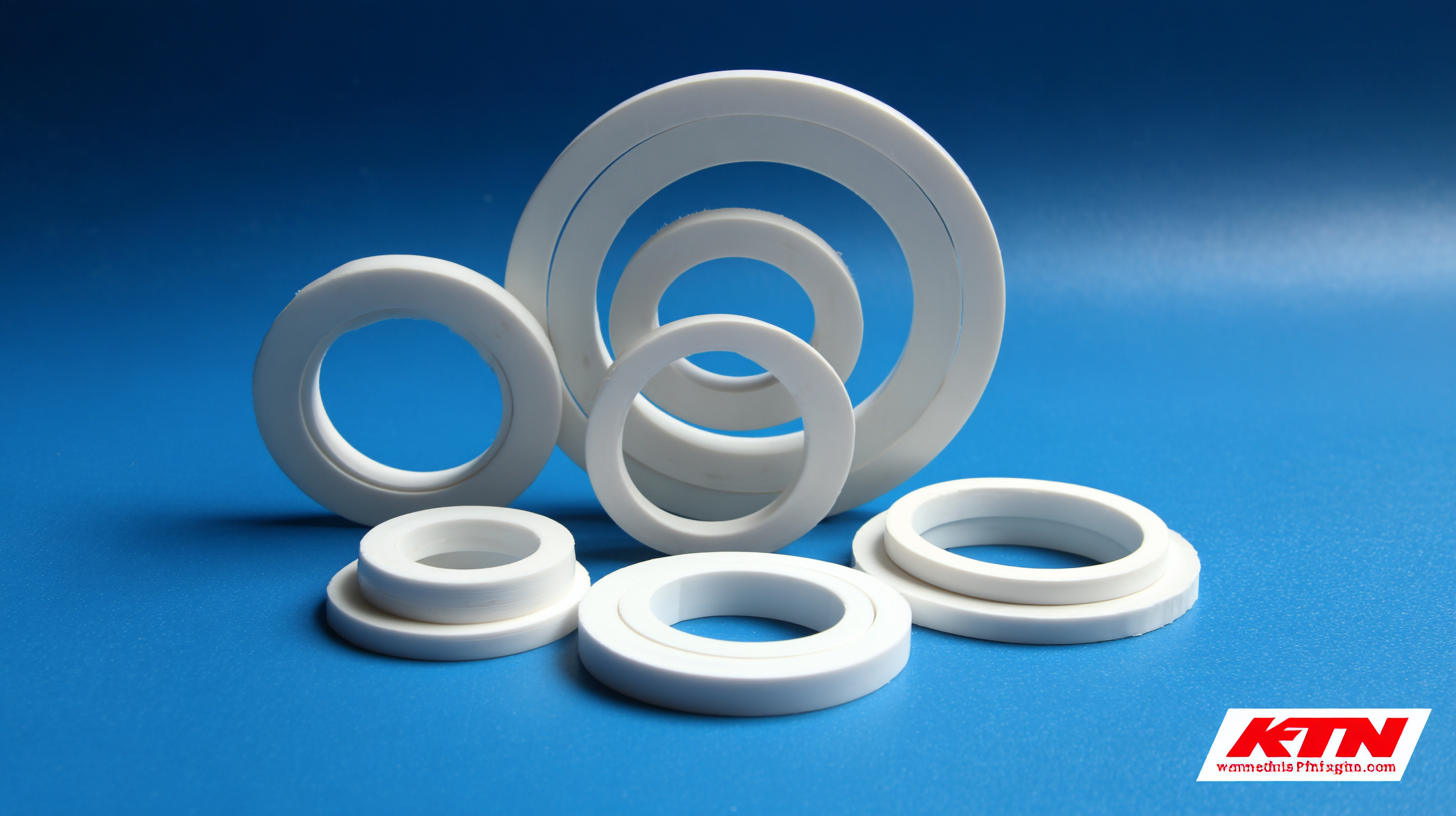

Polytetrafluoroethylene (PTFE) gaskets are widely known for their excellent chemical resistance, high-temperature stability, and low friction properties, making them indispensable in various sealing applications. Commonly used in rotary valves, quarter-turn ball valves, and pipeline gaskets, PTFE's unique attributes stem from its nonflammable, waxy nature and superior durability, which contribute to its popularity in industries ranging from chemical processing to food production. As the global market for PTFE is projected to reach USD 5.1 billion by 2033, industry professionals are increasingly seeking high-quality materials from reputable manufacturers.

Polytetrafluoroethylene (PTFE) gaskets are widely known for their excellent chemical resistance, high-temperature stability, and low friction properties, making them indispensable in various sealing applications. Commonly used in rotary valves, quarter-turn ball valves, and pipeline gaskets, PTFE's unique attributes stem from its nonflammable, waxy nature and superior durability, which contribute to its popularity in industries ranging from chemical processing to food production. As the global market for PTFE is projected to reach USD 5.1 billion by 2033, industry professionals are increasingly seeking high-quality materials from reputable manufacturers.

When selecting PTFE gaskets, consider the operating environment and specific application requirements. For instance, filled PTFE gaskets provide enhanced mechanical strength and resistance to wear and tear, making them suitable for more demanding applications. Additionally, it's worth noting that alternative materials, such as innovative polyurethane-based seals, are emerging as viable options for certain applications, offering unique benefits that may extend the lifespan of sealing solutions.

Tips: Always ensure compatibility of the gasket material with the media it will seal to prevent any chemical reactions. Regular inspections are crucial to maintaining seal integrity and performance, ensuring optimal operations in your systems.

When it comes to industrial applications, choosing the right gasket material is crucial for ensuring optimal performance and longevity. Premium PTFE gasket materials stand out for their exceptional chemical resistance and high-temperature tolerance, making them ideal for various industries including oil and gas, pharmaceuticals, and food processing. As the Industrial Gaskets Market is projected to reach USD 16.84 billion by 2030, it's evident that demand for high-quality materials is on the rise. This trend emphasizes the need for businesses to invest in reliable and durable gasket solutions.

Investing in premium PTFE gasket materials not only enhances operational efficiency but also contributes to long-term cost savings, aligning well with the broader trends in the industrial gaskets market.

PTFE gaskets are essential components in a variety of industrial applications, thanks to their excellent chemical resistance and durability. The manufacturing process of high-quality PTFE gaskets involves several key steps that ensure consistency and reliability. The foremost step is the selection of premium raw materials, which play a crucial role in the final product's performance. Top factories in China leverage advanced machinery and techniques to extrude and mold PTFE, resulting in gaskets that withstand extreme temperatures and pressures.

Tips for ensuring the best PTFE gaskets begin with understanding the specific requirements of your application. Always consult with manufacturers about the correct type of PTFE composite needed for optimal performance. Additionally, consider the impact of environmental conditions on gasket longevity. Regular inspections and maintenance can prevent failures, ensuring that your machinery operates smoothly.

Another tip is to choose a manufacturer that employs rigorous quality control processes during production. This guarantees that each PTFE gasket meets stringent industry standards, which is particularly crucial for sectors like pharmaceuticals where reliability is paramount. By focusing on these manufacturing processes and quality assurance measures, you can ensure that the PTFE gaskets you source will provide superior performance throughout their lifespan.

The industrial gaskets market is poised for significant growth, projected to reach USD 16.84 billion by 2030. A considerable portion of this expansion can be attributed to the increasing demand for durable and cost-effective sealing solutions in long-term applications. PTFE gaskets stand out in this realm, offering unique characteristics such as excellent chemical resistance and high thermal stability. These properties make them particularly suitable for industries ranging from petrochemicals to food processing, where longevity and reliability are critical.

When analyzing the cost-effectiveness of PTFE gaskets, it's essential to consider their lifespan and performance under extreme conditions. Although the initial investment may be higher compared to traditional gasket materials, the long-term savings generated from reduced maintenance costs and downtime can be substantial. According to recent industry reports, companies that implement high-quality PTFE gaskets often experience enhanced operational efficiency, aligning with the broader trends within the industrial gaskets market. With the right supplier, businesses can leverage the advantages of premium PTFE materials, ensuring robust sealing solutions that contribute to sustainable growth in a competitive landscape.

When choosing gasket materials for various applications, it's essential to compare the performance of PTFE gaskets with traditional gasket materials like rubber, cork, and paper. PTFE, or polytetrafluoroethylene, stands out due to its unique chemical resistance and high thermal stability, making it an ideal choice for aggressive environments. Traditional materials may falter under extreme conditions such as high temperatures or corrosive substances, leading to potential leaks and equipment failure. The advanced manufacturing processes of premium PTFE gaskets ensure an impeccable finish and superior sealing capabilities that often surpass those of conventional materials.

Another critical aspect of the comparative study is the longevity and durability of PTFE gaskets versus traditional options. PTFE gaskets are less prone to wear, tear, or degradation, which results in extended service life and reduced maintenance costs over time. In contrast, traditional gaskets may require frequent replacements, particularly in challenging operational settings. Additionally, the flexibility and compressibility of PTFE allow for effective sealing across various surfaces, enhancing its performance in dynamic applications where movement may compromise traditional gaskets. As industries evolve and seek more reliable sealing solutions, the advantages of PTFE gaskets become increasingly prominent in comparison to their traditional counterparts.

This chart compares the performance of PTFE gaskets and traditional gasket materials across key metrics, highlighting the superior attributes of PTFE.