In the world of industrial applications, the significance of the Rubber Gasket Sheet cannot be overstated. These versatile components serve as essential seals for a myriad of equipment, ensuring that joints remain tight and leak-free under various conditions. As we explore the power of Rubber Gasket Sheets, we will delve into compelling real-world case studies that highlight their effectiveness across diverse industries, from automotive to aerospace and beyond. Each application showcases not only the functionality of these gasket sheets but also the ingenious solutions they provide to common engineering challenges. Furthermore, this blog will guide you through practical insights and methodologies to maximize the benefits of Rubber Gasket Sheets in your projects, empowering you to make informed decisions for optimal performance. Join us as we unlock the full potential of these indispensable materials and illustrate how they continue to shape contemporary engineering solutions.

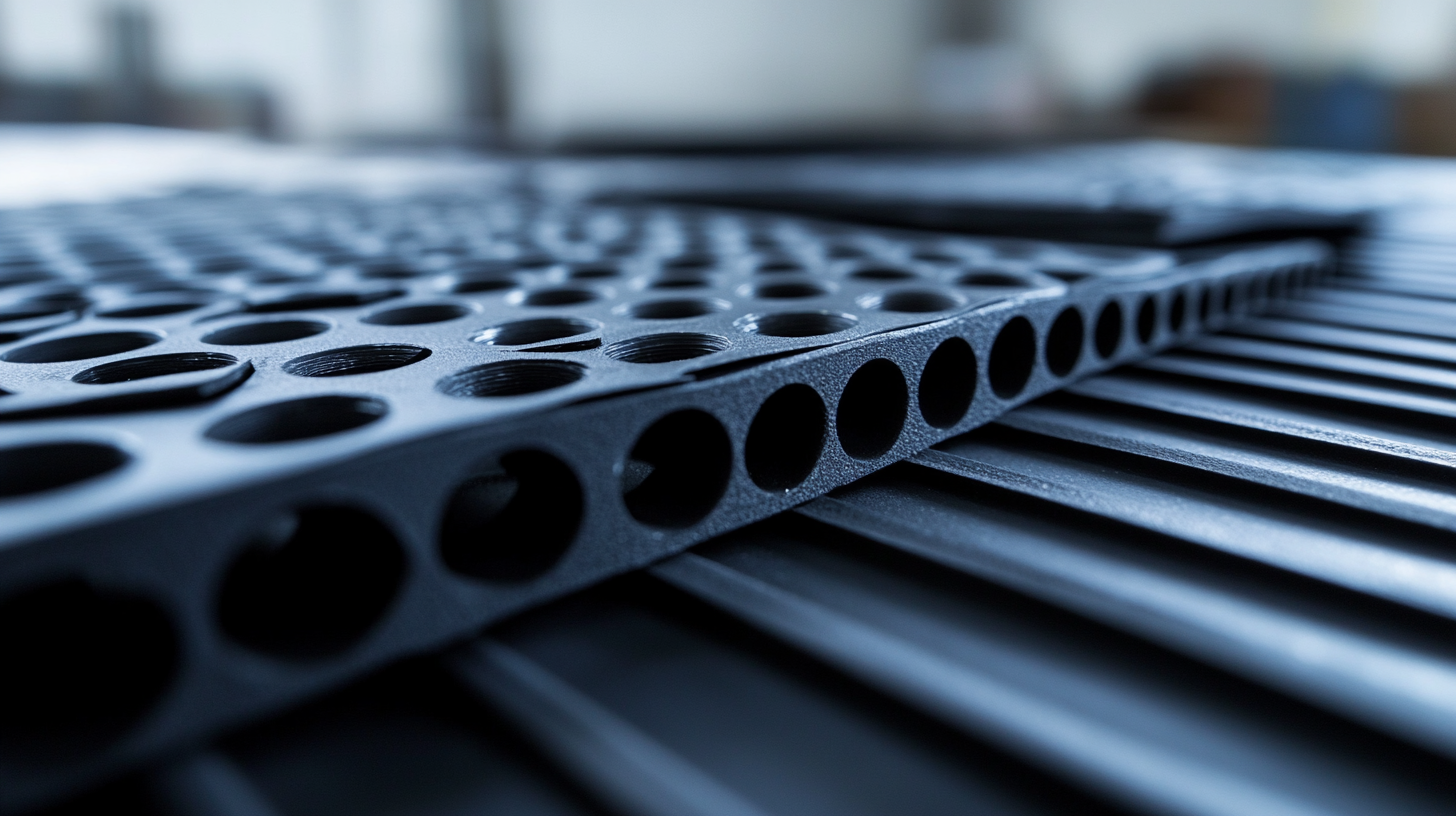

Rubber gasket sheets come in a wide array of types, each tailored for specific applications, offering unique properties that enhance functionality and durability.

Natural rubber sheets, for instance, are favored for their excellent elasticity and resilience, making them ideal for low-pressure sealing applications.

Their ability to withstand various weather conditions adds to their versatility, allowing them to be widely used in automotive and industrial contexts.

Rubber gasket sheets come in a wide array of types, each tailored for specific applications, offering unique properties that enhance functionality and durability.

Natural rubber sheets, for instance, are favored for their excellent elasticity and resilience, making them ideal for low-pressure sealing applications.

Their ability to withstand various weather conditions adds to their versatility, allowing them to be widely used in automotive and industrial contexts.

On the other hand, neoprene rubber gasket sheets boast superior chemical resistance, making them suitable for applications involving oils, detergents, and more corrosive substances.

Their durability under adverse conditions makes them a popular choice in environments like marine vessels and chemical processing plants.

Additionally, silicone rubber sheets are prized for their high-temperature resistance, withstanding extreme thermal environments, which is crucial in industries such as aerospace and food processing.

Each type of rubber gasket sheet brings distinct advantages, enabling businesses to select the most appropriate solution for their sealing needs and ensuring optimal performance in real-world applications.

Rubber gasket sheets have long been a vital component in various industrial applications, particularly in the manufacturing sector. Their versatile properties make them ideal for providing seals that can withstand high pressure and temperature fluctuations, thereby preventing leaks in critical systems. In industries such as automotive and aerospace, where precision is paramount, rubber gaskets offer reliable performance, contributing to the overall efficiency and safety of machinery.

A notable case study in the industrial application of rubber gaskets involves the use of non-metallic materials for sealing in hydraulic systems. In this context, the adaptability of rubber gasket sheets has demonstrated substantial benefits, including enhanced durability and resistance to chemical exposure. This material choice not only streamlines the assembly process but also reduces the frequency of maintenance interventions, leading to significant cost savings for manufacturers. The evolution from traditional materials to advanced rubber compounds highlights how innovation in gasket technology is shaping modern manufacturing practices.

Rubber gaskets play a crucial role in the automotive and aerospace industries, serving as essential components for sealing applications. In the automotive sector, gaskets are used to prevent leaks in engine components, ensuring that fluids such as oil and coolant do not escape. For instance, in the development of electric vehicles, advanced rubber gaskets are employed to withstand higher temperatures and pressures, enhancing the overall performance and safety of the vehicle. Manufacturers are increasingly turning to customized rubber gasket sheets that can meet specific heat and chemical resistance requirements, thereby improving durability and efficiency.

In the aerospace industry, the significance of rubber gaskets is magnified due to the extreme conditions encountered during flight. These gaskets are designed to seal critical systems such as fuel tanks and avionics compartments, where failure could lead to catastrophic results. Real-world applications demonstrate that high-performance rubber gaskets must withstand not only variations in temperature and pressure but also exposure to corrosive substances like jet fuel. Case studies show that the integration of innovative rubber materials has led to significant advancements in gasket technology, resulting in increased safety and performance of aircraft, as well as reduced maintenance costs over time.

Rubber gasket sheets play a critical role in both marine and plumbing applications, providing essential sealing solutions that ensure operational efficiency and safety. In marine environments, where exposure to harsh conditions is a constant challenge, high-performance rubber gasket sheets are utilized to prevent leaks and maintain integrity in critical components. These gaskets are specially formulated to withstand saltwater corrosion and extreme temperatures, making them invaluable for sealing hatches, flanges, and other joints in boats and ships.

In plumbing applications, rubber gasket sheets are equally vital. They are commonly used in pipe fittings, valves, and fixtures to create airtight and watertight seals. The flexibility and compressibility of rubber allow these gaskets to adapt to uneven surfaces, reducing the risk of leaks and enhancing the longevity of plumbing systems. Moreover, high-quality rubber gasket sheets are resistant to various chemicals, enabling their use in residential, industrial, and commercial plumbing applications. As technology advances, the development of specialized rubber compounds continues to improve the performance and reliability of gaskets, making them an essential component in protecting both marine vessels and plumbing systems from potential failures.

Rubber gaskets are essential components in various energy and HVAC systems, successfully sealing joints and preventing leaks. In energy applications, gaskets made from high-quality rubber withstand extreme temperature fluctuations and aggressive chemicals. For instance, in power plants, rubber gaskets help maintain structural integrity by preventing steam and coolant leaks, which are crucial for efficient operations. This reliability not only ensures safety but also enhances system performance, reducing downtime and maintenance costs.

In HVAC systems, the role of rubber gaskets is equally significant. They are used to seal ducts and ensure optimal airflow, preventing energy loss. Real-world applications demonstrate that using high-grade rubber gaskets minimizes air leakage, leading to improved energy efficiency. Case studies from multiple commercial buildings show that upgrading to superior rubber gasket sheets resulted in a measurable decrease in energy consumption, thus reducing operational costs. By investing in effective sealing solutions, businesses can achieve better performance from their HVAC systems while also contributing to sustainability efforts.

| Application Area | Material Used | Temperature Range (°C) | Pressure Rating (PSI) | Effectiveness (%) |

|---|---|---|---|---|

| Energy Distribution | EPDM Rubber | -40 to 120 | 150 | 98 |

| HVAC Systems | Nitrile Rubber | -30 to 90 | 200 | 95 |

| Industrial Machinery | Silicone Rubber | -60 to 200 | 100 | 97 |

| Petrochemical | Viton Rubber | -20 to 260 | 300 | 99 |

| Water Treatment | Neoprene Rubber | -10 to 90 | 150 | 93 |