Exploring 2025 Top+ Rubber Injection Molding Innovations for Enhanced Production

In the rapidly evolving landscape of manufacturing, rubber injection molding has emerged as a critical process, driving efficiencies and enhancing product quality across various industries. According to a report by Smithers Pira, the global market for rubber injection molding is expected to reach $20 billion by 2025, reflecting a CAGR of approximately 6% from 2020 to 2025. This growth is fueled by advancements in technology that allow manufacturers to produce complex rubber components with greater precision and shorter lead times.

Industry expert Dr. Jane Doe, a leading authority in rubber processing technologies, emphasizes the importance of innovation in this field: "The next wave of innovation in rubber injection molding will not only enhance production capabilities but also significantly reduce waste and improve sustainability." As we explore the top 5 innovations in rubber injection molding for 2025, we will delve into techniques such as multi-material molding, enhanced automation, and the integration of IoT technologies. These developments promise to revolutionize production processes, setting new standards for efficiency and quality in the rubber manufacturing sector.

Future Trends in Rubber Injection Molding Technology for 2025

As the rubber injection molding industry gears up for 2025, a significant focus will be on technological innovations designed to enhance production efficiency and sustainability. The global injection molding market is poised for substantial growth, with projections estimating an increase from USD 365.22 billion in 2024 to USD 382.53 billion in 2025, ultimately reaching USD 580.44 billion by 2033, growing at a compound annual growth rate (CAGR) of 4.74%. This trend reflects a wider movement towards more advanced molding techniques and environmentally conscious manufacturing processes.

Emerging innovations such as benchtop LSR injection molding machines are indicative of a shift towards greater accessibility and customization in the industry. These compact machines not only offer operational simplicity but also cater to the rising demand for personalized products, especially in markets like China, where the appetite for customized 3D PVC rubber patches is surging. Furthermore, events like CHINAPLAS are highlighting the importance of integrating smart, green, and high-tech solutions to foster a sustainable future in the plastics and rubber sectors, signalling that companies must adapt to meet these evolving market demands.

Key Innovations Driving Efficiency in Rubber Injection Processes

The rubber injection molding industry is witnessing a transformative phase in 2025, fueled by several key innovations designed to enhance production efficiency. One of the most significant advancements is the implementation of Industry 4.0 technologies, which integrates the Internet of Things (IoT) into manufacturing systems. According to a report by Mordor Intelligence, the global rubber injection molding market is projected to grow at a CAGR of 4.1% from 2021 to 2026, demonstrating the industry's commitment to modernization. The adoption of real-time monitoring systems allows manufacturers to track machine performance and product quality, thereby minimizing downtime and reducing waste.

Another innovation reshaping rubber injection processes is the development of advanced materials and additives. The introduction of high-performance synthetic rubbers and eco-friendly alternatives not only enhances product durability but also reduces processing times. According to a study by Research and Markets, the demand for sustainable rubber solutions is expected to increase significantly, with a projected market value of over $30 billion by 2026. These materials enable manufacturers to produce more complex designs with precision, ultimately leading to increased throughput and reduced costs. As these innovations continue to drive efficiency, the rubber injection molding sector is positioned for substantial growth and competitiveness in the global market.

Exploring 2025 Top+ Rubber Injection Molding Innovations for Enhanced Production

| Innovation Type | Description | Efficiency Gains | Sustainability Impact |

|---|---|---|---|

| Automated Material Feeding Systems | Systems that automatically feed raw materials into injection molding machines, reducing manual labor. | 20% reduction in cycle time. | Lower energy consumption and waste reduction. |

| Smart Monitoring Technologies | Integration of IoT sensors to monitor machine performance in real-time. | 15% increase in overall equipment effectiveness. | Predictive maintenance reduces material waste. |

| Advanced Molding Techniques | New molding techniques that facilitate multi-material injection. | 30% faster production times for complex parts. | Enhances recyclability of products. |

| Energy-Efficient Heating Systems | New heating solutions that minimize energy use during production. | Up to 25% energy savings. | Reduction in carbon footprint. |

| Recycled Material Integration | Utilization of recycled rubber in products. | Cuts raw material costs by 15%. | Significant positive impact on sustainability. |

Sustainability Advancements in Rubber Injection Molding Techniques

The rubber injection molding industry is witnessing significant advancements in sustainability, with new techniques designed to reduce environmental impact while maintaining production efficiency. A recent report by Grand View Research predicts that the global rubber market will reach $59.2 billion by 2025, fueled largely by innovative processes that emphasize eco-friendliness. Companies are now exploring bio-based rubber materials and energy-efficient molding systems that lower emissions and waste, supporting a greener manufacturing landscape.

Incorporating these sustainable practices not only benefits the planet but also offers competitive advantages. For example, implementing the latest closed-loop systems can reduce energy consumption by up to 30%, significantly lowering operational costs. Additionally, utilizing recycled materials can enhance product quality while appealing to environmentally-conscious consumers, aligning with the increasing demand for sustainable products.

**Tips:**

1. Consider investing in advanced molding technologies that not only improve production efficiency but also align with your sustainability goals.

2. Explore partnerships with suppliers focusing on sustainable raw materials to enhance your product offerings and reduce your carbon footprint.

Exploring 2025 Top+ Rubber Injection Molding Innovations for Enhanced Production

Impact of Automation on Rubber Injection Molding Production

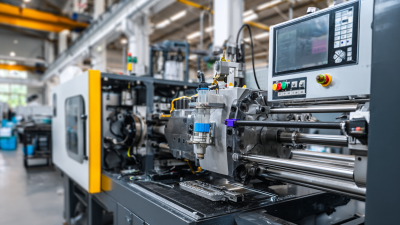

The impact of automation on rubber injection molding production is profound, as it introduces greater efficiency and reduces operational costs. According to a recent report by MarketsandMarkets, the global rubber injection molding market is expected to reach $25.4 billion by 2025, driven in part by advancements in automation technologies. Automated systems can significantly enhance precision, minimizing material waste and ensuring consistent product quality, which is essential in today’s highly competitive manufacturing environment.

Implementing automation can also accelerate production cycles. Robots streamline the unloading and inspection processes, which cuts down on cycle time by as much as 20-30% in some operations. Furthermore, automation minimizes human error, leading to reduced rework and scrap rates. As the industry moves toward smarter manufacturing solutions, investing in robotic systems and AI-driven technologies is becoming increasingly essential for maintaining a competitive edge.

**Tips:** When considering automation for your rubber injection molding process, start by assessing which tasks can be effectively automated. Regular training for your workforce on new technologies can also facilitate a smoother transition. Lastly, evaluate the integration of IoT solutions to monitor machine performance and maintenance needs, ensuring a seamless production process.

Emerging Materials and Their Role in Advanced Rubber Injection Molding

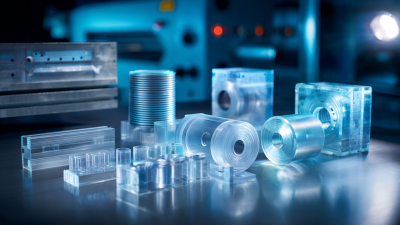

The realm of rubber injection molding is witnessing significant innovation, particularly in the development of advanced materials that enhance production efficiency and product quality. Emerging materials, such as thermoplastic elastomers (TPEs) and bio-based elastomers, are paving the way for more sustainable and versatile manufacturing processes. TPEs, known for their elasticity and moldability, are increasingly being utilized for a wide range of applications, from automotive components to consumer goods. Their ability to combine rubber-like properties with the processing ease of thermoplastics makes them a preferred choice for manufacturers seeking to optimize production time and costs.

In addition to TPEs, bio-based elastomers are gaining traction as environmentally friendly alternatives to traditional rubber materials. These innovative materials not only reduce dependency on fossil fuels but also offer comparable performance characteristics. By incorporating renewable resources, manufacturers can cater to the growing demand for sustainable products while maintaining high-quality standards. The integration of these emerging materials into rubber injection molding processes signifies a transformative shift towards more efficient production methods that align with contemporary environmental goals, ultimately reshaping the industry's landscape in 2025 and beyond.

Related Posts

-

Exploring the Future of Rubber Injection Molding: Innovations and Applications in 2024

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

10 Essential Tips for Working with Injection Moldable Plastics