Top Benefits of Medical Injection Moulding for Healthcare Innovations

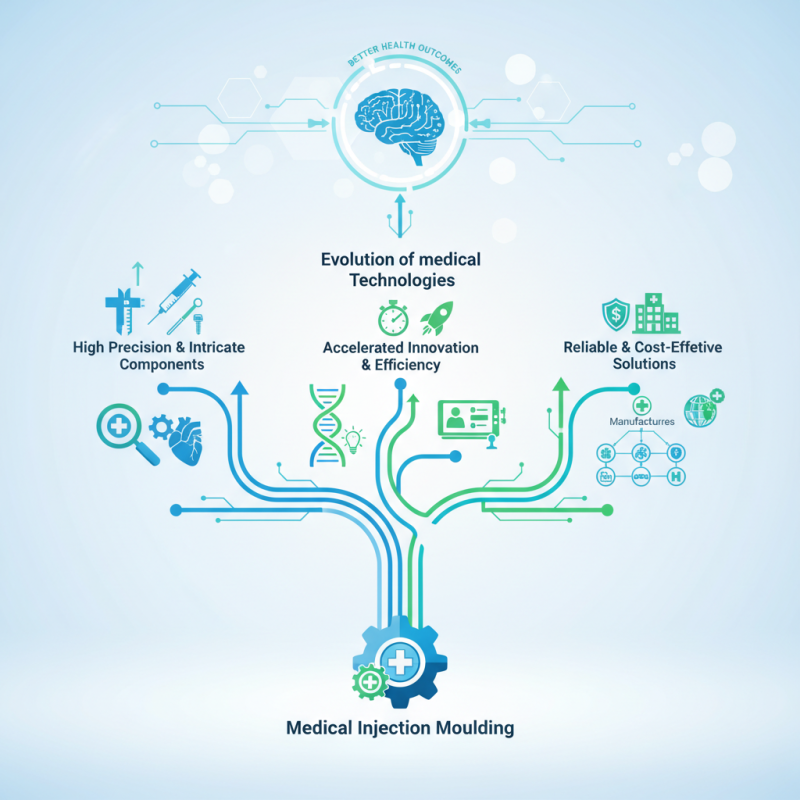

In the rapidly evolving healthcare landscape, the significance of medical injection moulding cannot be overstated. This advanced manufacturing technique has revolutionized the production of medical devices, enabling the creation of intricate components with high precision and efficiency. According to Dr. Emily Carter, a leading expert in the field of biomedical engineering, "The adoption of medical injection moulding has not only improved the quality of healthcare products but has also accelerated the pace of innovation in the medical sector."

As healthcare practitioners seek novel solutions to enhance patient care, the integration of medical injection moulding plays a pivotal role in developing state-of-the-art devices. From syringes and surgical instruments to diagnostic equipment, this technology facilitates the production of reliable and cost-effective solutions that meet stringent regulatory requirements. In doing so, medical injection moulding fosters collaborations among manufacturers, healthcare providers, and researchers, ultimately driving advancements that can lead to better health outcomes for patients worldwide.

In this article, we will explore the top benefits of medical injection moulding, highlighting how it serves as a cornerstone for healthcare innovations and contributes to the evolution of medical technologies that shape the future of patient care.

Overview of Medical Injection Moulding in Healthcare Industry

Medical injection moulding has emerged as a pivotal technology in the healthcare industry, facilitating the production of complex and precise medical devices. This manufacturing process allows healthcare providers to create high-quality products that meet stringent regulatory standards. With the capability to use biocompatible materials, injection moulding enables the production of everything from syringes to surgical instruments, ensuring that they are both safe for patients and effective in their intended uses.

Tips: When considering medical injection moulding, it is crucial to focus on material selection. Opt for materials that not only comply with medical regulations but also possess the necessary durability and flexibility for their specific applications. Additionally, collaboration with experienced moulding engineers can greatly enhance the design process, allowing for innovative solutions that cater to the evolving needs of the healthcare sector.

Another benefit of medical injection moulding is its efficiency in mass production. This method allows for consistent replication of complex shapes, which is essential in reducing costs and lead times for medical products. By optimizing the design for manufacturability, healthcare companies can streamline production processes and significantly scale their operations to meet increasing demand.

Tips: Always conduct thorough testing and validation of moulded products before full-scale production. This practice helps identify potential issues early in the development process, ensuring compliance with safety and performance standards while minimizing the risk of costly recalls or redesigns later on.

Key Advantages of Using Injection Moulding for Medical Devices

Injection moulding has become an essential method in the production of medical devices, offering numerous key advantages that contribute significantly to healthcare innovations. One of the most considerable benefits is the capability for high-volume production with consistency and precision. According to a report by the Medical Device and Diagnostics Industry (MD+DI), the market for medical injection moulding is expected to reach $3.7 billion by 2024, underscoring the increasing reliance on this technology for efficient manufacturing processes. The ability to produce complex geometries with minimal waste makes injection moulding not only cost-effective but also environmentally sustainable.

Another notable advantage is the flexibility in material selection. Medical injection moulding allows manufacturers to utilize a wide range of biocompatible polymers, which can be tailored to meet specific performance requirements of various medical applications. For instance, a study from Grand View Research indicates that bioplastics are becoming increasingly popular in medical device production, accounting for a significant portion of the overall materials used. This versatility enables the creation of devices that are not only functional but also safe for patient use, ensuring compliance with stringent regulatory standards in the healthcare industry.

Furthermore, injection moulding offers rapid prototyping capabilities, which is critical for the fast-paced nature of healthcare innovations. The ability to quickly iterate designs and produce prototypes helps in reducing time-to-market for new medical innovations. A report from The Freedonia Group notes that the global demand for medical components and devices is projected to grow by 5.1% annually. This demand highlights the importance of efficient production methods like injection moulding in meeting market needs while fostering the development of cutting-edge healthcare solutions.

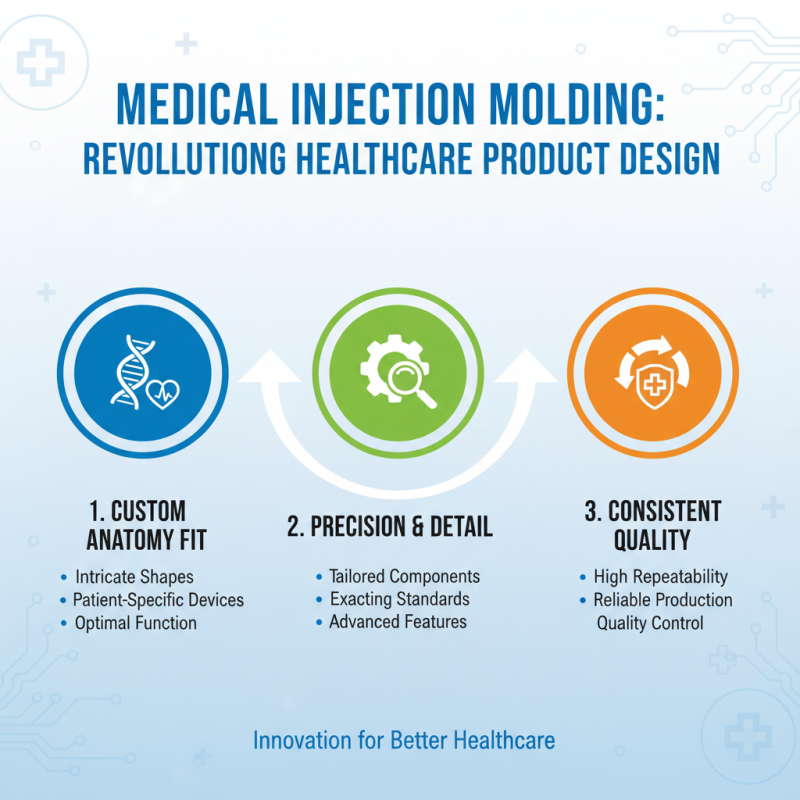

Impact on Product Design and Customization in Healthcare Solutions

Medical injection moulding has revolutionized product design and customization in the healthcare sector, enabling the creation of highly specialized components that meet exacting standards. One of the standout benefits is the ability to produce intricate shapes and features that are tailored to specific medical applications. This level of precision ensures that devices not only fit the unique anatomy of patients but also function optimally in various medical procedures. Additionally, the high repeatability of the injection moulding process allows for consistent production of these complex designs, which is crucial in maintaining quality control in healthcare products.

Moreover, the adaptability of injection moulding facilitates rapid prototyping and the exploration of innovative designs. Healthcare professionals can collaborate with manufacturers to create bespoke solutions that address the evolving needs of patients and practitioners alike. This customization can lead to enhancements in comfort and effectiveness of medical devices, such as improved ergonomic shapes in surgical instruments or personalized features in drug delivery systems. As a result, medical injection moulding significantly contributes to better patient outcomes and enhances the overall effectiveness of healthcare solutions, making it an invaluable technique in the ongoing development of innovative medical technology.

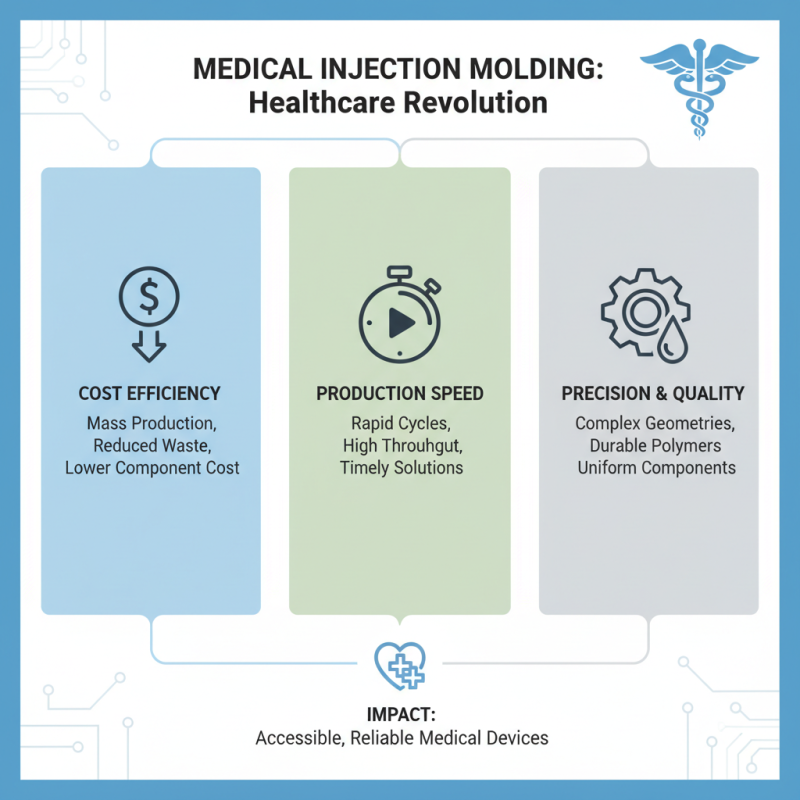

Cost Efficiency and Production Speed in Medical Injection Moulding

Medical injection moulding has revolutionized the healthcare industry by offering significant cost efficiency and production speed, which are critical for delivering timely medical solutions. This manufacturing process allows for the mass production of high-quality components at a lower cost compared to traditional methods. By utilizing advanced polymers, manufacturers can create intricate and durable parts that meet the stringent requirements of medical applications. The ability to produce complex geometries in a consistent manner reduces the likelihood of defects and ensures uniformity across large batches, ultimately driving down production costs.

In addition to cost savings, medical injection moulding enhances production speed through a streamlined workflow. The process is highly automated, which minimizes manual labor and accelerates the manufacturing timeline. Rapid prototyping can also occur, allowing healthcare innovators to iterate designs quickly and efficiently. This agility is particularly valuable in an industry where speed to market can be the difference between life-saving innovations and missed opportunities. Consequently, the combination of cost efficiency and swift production capabilities positions medical injection moulding as a vital asset in the ongoing advancement of healthcare technologies.

Enhancing Sterility and Safety in Healthcare Products through Moulding

Medical injection moulding has emerged as a

transformative technology in the healthcare sector,

significantly enhancing the sterility and safety of healthcare products. The precision offered by

injection moulding enables the production of complex shapes with tight tolerances,

which is critical for devices that require exact specifications. According to a report by MarketsandMarkets, the

global medical injection moulding market is projected to reach USD 3.24 billion

by 2025, growing at a CAGR of 6.9%. This growth underscores the

importance of this technology in meeting the ever-increasing demands for

safe and reliable medical products.

One of the primary advantages of injection moulding in healthcare is the ability to produce

single-use disposable products that minimize the risk of

cross-contamination. By utilizing sterile materials and

controlled manufacturing environments, manufacturers can ensure that the final products meet

stringent safety standards. The World Health Organization

emphasizes that maintaining sterility is vital for infection prevention, and injection moulded devices can be

designed to be tamper-proof and maintain their sterility

until use. Furthermore, research indicates that the implementation of advanced manufacturing techniques such as

injection moulding can lead to a 30% reduction in the risk of

device-related infections, highlighting its critical role in enhancing patient safety and healthcare outcomes.

Related Posts

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry