Top 10 Benefits of Rubber Injection Molding for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, rubber injection molding has emerged as a pivotal technique, widely recognized for its versatility and efficiency. According to a recent industry report by Grand View Research, the rubber injection molding market is expected to reach $10.65 billion by 2025, growing at a CAGR of 4.7%. This surge reflects the increasing demand for high-quality rubber products across various sectors, including automotive, healthcare, and consumer goods.

Experts in the field highlight the transformative benefits of this manufacturing method. Renowned rubber technology specialist Dr. Jane Holloway states, "Rubber injection molding not only streamlines production processes, but also enhances product durability and precision." Her insights underscore the effectiveness of rubber injection molding in meeting the rigorous standards of modern manufacturing. By adopting this innovative approach, businesses can leverage significant advantages such as reduced waste, lower production costs, and superior product consistency, ensuring they remain competitive in a challenging market.

Experts in the field highlight the transformative benefits of this manufacturing method. Renowned rubber technology specialist Dr. Jane Holloway states, "Rubber injection molding not only streamlines production processes, but also enhances product durability and precision." Her insights underscore the effectiveness of rubber injection molding in meeting the rigorous standards of modern manufacturing. By adopting this innovative approach, businesses can leverage significant advantages such as reduced waste, lower production costs, and superior product consistency, ensuring they remain competitive in a challenging market.

As we delve into the top 10 benefits of rubber injection molding for your manufacturing needs, we will explore how this technique can not only boost operational efficiency but also drive growth and innovation in your business.

Top 10 Benefits of Rubber Injection Molding for Your Manufacturing Needs

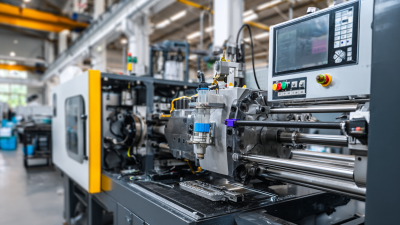

Rubber injection molding presents a myriad of advantages that are becoming increasingly essential for modern manufacturing needs. With the global injection molding market projected to grow from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, with a compound annual growth rate (CAGR) of 4.74%, the demand for efficient manufacturing processes is clear. Rubber injection molding not only allows for high precision and complex shapes but also enhances production efficiency by minimizing waste and reducing cycle times.

Furthermore, as companies navigate a competitive and environmentally-conscious landscape, the innovation of low-pressure injection molding stands out as a sustainable approach to plastics manufacturing. This method not only reduces energy consumption but also ensures greater material flexibility, catering to the rising demand for customized products. Reports indicate a surge in demand for personalized items, with suppliers adapting to the market's preferences. As industries focus on sustainability, the benefits of rubber injection molding will continue to play a critical role in driving advancements and ensuring competitive edge in the manufacturing sector.

Enhanced Production Efficiency: Reduce Cycle Times and Boost Output by Up to 30%

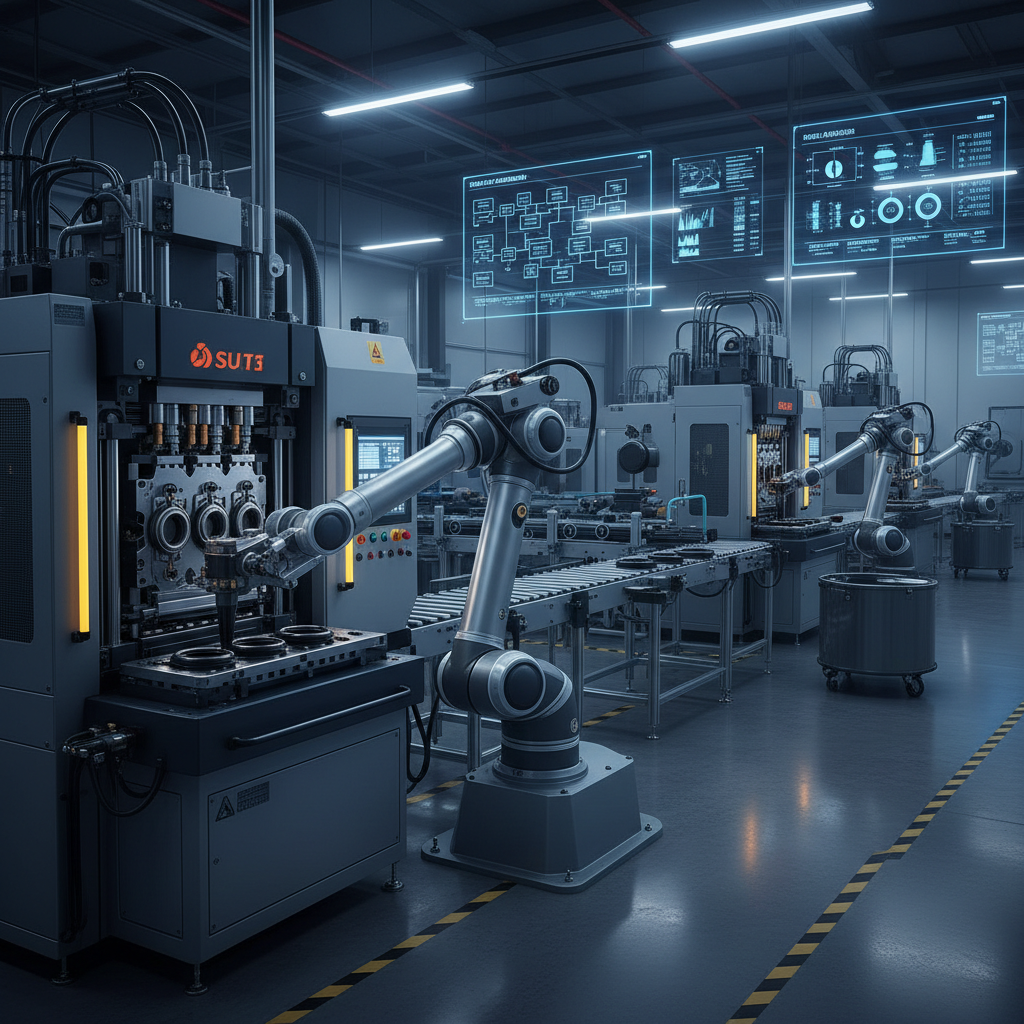

Rubber injection molding is revolutionizing manufacturing processes by significantly enhancing production efficiency. With advancements in technology, companies have reported a potential reduction in cycle times and an increase in output by up to 30%, allowing manufacturers to respond swiftly to market demands. For instance, the integration of AI in manufacturing is streamlining processes, ensuring consistent quality, and facilitating faster production capabilities.

The ability to optimize workflows with smart robotics and automation technologies is increasingly vital for businesses aiming to maintain competitive advantages in the industry.

Furthermore, the application of Digital Twin technology exemplifies how manufacturers can achieve flexibility and speed. By creating virtual representations of their production processes, manufacturers can simulate various scenarios and optimize production planning accordingly.

Studies indicate that implementing such innovations can lead to substantial operational improvements, further validating the push towards advanced injection molding techniques. The synergy between rubber injection molding and emerging technologies underscores a pivotal shift towards maximizing efficiency and productivity in the manufacturing sector, ultimately driving growth and profitability.

Cost-Effective Solutions: Lower Material Waste and Operating Costs through Precision Molding Techniques

Rubber injection molding has emerged as a

game-changer in the manufacturing sector, particularly when it

comes to cost-effective solutions. According to a report by the Rubber Manufacturers Association, utilizing precision molding techniques can reduce material waste by up to

30%. This not only conserves raw materials but also translates to

significant savings on operating costs. For manufacturers looking to optimize their production processes, the

accuracy of rubber injection molding ensures that parts are produced with minimal excess material, reducing the

need for secondary operations, which further cuts down costs and time.

Moreover, precision molding techniques enhance the overall efficiency of manufacturing lines. A study published

in the Journal of Manufacturing Science and Engineering highlighted that the cycle

times for quality parts in rubber injection molding can be decreased by as much as

20% compared to traditional molding methods. By minimizing

downtime and maximizing output, companies can improve their return on investment considerably. This efficiency

is particularly critical in today’s competitive market, where managing

production costs without sacrificing quality can determine a company’s success. As such, embracing rubber injection

molding not only benefits the bottom line but also supports sustainable manufacturing practices through reduced waste.

Superior Design Flexibility: Achieve Complex Geometries with Tolerances as Tight as ±0.1 mm

Rubber injection molding stands out in the manufacturing landscape due to its superior design flexibility, allowing for the creation of complex geometries that meet stringent tolerance requirements. According to a report by the International Association of Plastics Distribution, manufacturers increasingly demand precision in design, with tolerances often as tight as ±0.1 mm becoming the norm. This level of accuracy is essential in industries such as automotive and aerospace, where even the smallest deviation can lead to significant performance issues or failures.

The flexibility in rubber injection molding not only permits intricate designs but also allows for comprehensive customization options, making it suitable for a wide array of applications. For instance, a study published in the Journal of Manufacturing Science and Engineering indicated that designs incorporating complex features can be produced with minimal post-processing and finishing steps, ultimately reducing leads time and costs. By utilizing advanced molds and control systems, manufacturers can seamlessly create intricate patterns and shapes, that cater to the specific demands of their projects, thus optimizing both form and function.

Improved Product Consistency: Ensuring Uniform Quality with Automated Injection Processes in Multiple Runs

Rubber injection molding presents a significant advantage in manufacturing, especially when it comes to product consistency. By utilizing automated injection processes, manufacturers can achieve uniform quality across multiple production runs. According to a study by the Society of Plastics Engineers, implementing automated systems can reduce variations in product dimensions by up to 70%, leading to enhanced reliability for consumers and businesses alike. This is particularly crucial in industries requiring strict tolerances, such as automotive and medical device manufacturing.

Furthermore, the consistency offered by rubber injection molding minimizes scrap rates, thus optimizing material usage. The American Institute for Medical and Biological Engineering reports that enhanced process control can lead to a decrease in waste by approximately 30%. This not only contributes to more sustainable manufacturing practices but also results in significant cost savings over time. Automating the injection molding process ensures that manufacturers can replicate precise designs with minimal deviations, fostering trust from clients and ensuring high standards of quality assurance are maintained.

Top 10 Benefits of Rubber Injection Molding for Your Manufacturing Needs

This chart illustrates the top benefits of rubber injection molding, highlighting the importance of improved product consistency and other key advantages over traditional manufacturing methods.

Conclusion

Rubber injection molding offers numerous advantages that can significantly enhance manufacturing processes. One of the primary benefits is enhanced production efficiency, allowing companies to reduce cycle times and increase output by up to 30%. This technique is also cost-effective, as it minimizes material waste and operating costs through precise molding methods. Furthermore, rubber injection molding provides superior design flexibility, enabling manufacturers to create complex geometries with tight tolerances of ±0.1 mm.

In addition to efficiency and cost benefits, this method ensures improved product consistency by utilizing automated injection processes, which maintain uniform quality across multiple production runs. Lastly, rubber injection molding supports sustainability in manufacturing by utilizing recyclable materials and reducing environmental impact by up to 50%. Overall, these advantages make rubber injection molding a valuable choice for modern manufacturing needs.

Related Posts

-

Exploring the Future of Rubber Injection Molding: Innovations and Applications in 2024

-

Exploring 2025 Top+ Rubber Injection Molding Innovations for Enhanced Production

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

Why Plastic Extrusion is the Key to a $300 Billion Manufacturing Sector Growth?

-

Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting

-

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends