Best Injection Machine for 2026 What to Look For?

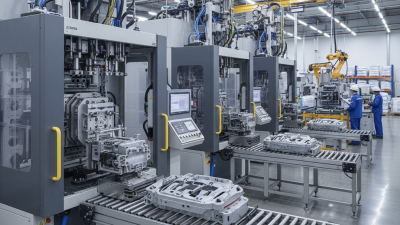

In the rapidly evolving world of manufacturing, the choice of an injection machine can significantly impact production efficiency. According to a report by Market Research Future, the global injection molding machine market is expected to reach $19.8 billion by 2026. This growth emphasizes the need for businesses to select the best machinery for their needs. As Steve Roberts, an injection machine industry expert, states, “Choosing the right injection machine today ensures your business's competitive edge tomorrow.”

An injection machine’s technology directly influences product quality and production speed. Features like energy efficiency, precision, and automation capabilities are critical factors to consider. Many manufacturers grapple with the decision of what specifications best align with their operational goals. Some may overlook smaller details, which can result in inefficiencies. A study by Technavio highlights that nearly 30% of companies regret their choices due to inadequate research.

Investing in a high-quality injection machine is not merely a cost; it's an essential step towards innovation. However, the industry presents complexities. Companies often struggle to balance upfront costs with long-term benefits. The right decision requires reflection on both immediate and future production needs.

Types of Injection Machines and Their Applications for 2026

When considering injection machines for 2026, understanding their types and applications is crucial. Injection molding machines largely fall into two categories: hydraulic and electric. Hydraulic machines are known for their power and durability. They excel in large-scale production but can have higher operational costs. Electric machines, on the other hand, offer precision and energy efficiency. They are increasingly popular in the automotive and medical sectors, where accuracy is paramount.

Recent industry reports indicate that the global injection molding machine market is expected to grow by 4.8% annually. This growth is driven by rising demand in the packaging sector, which comprises a significant portion of machine use. Additionally, new materials and bioplastics are emerging, creating challenges for existing machinery. Companies must select machines that can handle these innovations while maintaining efficiency.

Investing in the right machine entails understanding specific needs and production volumes. Some industries require rapid changes in design, demanding versatile machines. However, not all machines can adapt quickly. It’s essential to evaluate the long-term implications of machine choice, including maintenance and operational costs. Choosing an injection machine is a process filled with variables, each requiring careful consideration as the industry evolves.

Best Injection Machine Types and Their Applications for 2026

Key Features to Consider When Selecting an Injection Machine

When selecting an injection machine, several key features should guide your decision. The machine's size is critical. It needs to fit into the existing workspace without causing clutter. A compact design can be beneficial, but ensure it is still efficient.

Another essential feature is the injection speed. Faster machines can increase productivity, but they might compromise precision. Balance is key here. Did you consider how this affects your production line? Adjusting to rapid changes takes time.

Don't overlook energy efficiency. Machines that consume less power can save costs over time. Look for models that offer energy-saving modes. They are appealing for both budgets and the environment.

Tips: Always check user reviews. They provide real-world insights. Test machines if possible. It helps you understand their operation better. Lastly, think about after-sales service. A machine is only as good as the support you receive.

Energy Efficiency and Cost-Effectiveness in Injection Machinery

When selecting the best injection machine for 2026, energy efficiency and cost-effectiveness are crucial. Reports indicate that energy consumption can account for up to 40% of a manufacturing facility's operational costs. Choosing machines with advanced energy-efficient technologies can significantly reduce these expenses. For example, hydraulic systems that utilize variable speed pumps often demonstrate 20-30% reduction in energy use compared to traditional models.

Additionally, manufacturers are prioritizing machines with lower operational and maintenance costs. More efficient units not only minimize electricity bills but also require less maintenance. A recent study highlighted that companies can save an average of 15% annually on maintenance costs by switching to improved energy-efficient machinery. Investing in high-quality components can lower the frequency of repairs, leading to less downtime.

However, challenges persist in finding the perfect balance between upfront costs and long-term savings. Some energy-efficient models come with higher initial price tags. Companies need to carefully analyze their production needs and consider return on investment. Evaluating total cost of ownership becomes essential for informed decision-making. It's a complex equation, but the push for sustainability drives many to seek better options in the market.

Best Injection Machine for 2026: What to Look For?

| Injection Machine Type | Energy Efficiency Rating | Cost-Effectiveness ($) | Recommended Applications |

|---|---|---|---|

| Hydraulic Injection Machine | A+ (High) | 25,000 - 35,000 | Automotive Parts, Large Components |

| Electric Injection Machine | A++ (Very High) | 30,000 - 45,000 | Consumer Goods, Packaging |

| Hybrid Injection Machine | A (Moderate) | 28,000 - 38,000 | Medical Devices, Electronics |

| Vertical Injection Machine | B (Standard) | 20,000 - 30,000 | Small Parts, Inserts |

| Micro Injection Machine | A+ (High) | 35,000 - 50,000 | Precision Components, Aerospace |

Technological Advancements in Injection Molding for 2026

As we approach 2026, the injection molding industry is witnessing significant technological advancements. These innovations promise to improve efficiency and sustainability. New materials are emerging, allowing for lighter and stronger parts. Enhanced automation techniques are also making production processes faster and more precise. The goal is to meet the rising demand for customized solutions.

Another critical development is the integration of artificial intelligence. AI can optimize machine operations and predict maintenance needs. This ensures minimal downtime and higher productivity. However, the reliance on technology raises concerns. Will skilled labor become obsolete? It's essential to find a balance between automation and human expertise.

Sustainability is a pressing issue as well. Cutting down on waste and energy consumption is vital. Companies are exploring eco-friendly materials and processes. However, transitioning to greener practices can be challenging. The upfront costs may deter some manufacturers. Yet, embracing these changes is crucial for future success.

Maintenance and Support Services for Injection Machines

When choosing an injection machine, maintenance and support services are crucial. Regular maintenance can prevent unexpected breakdowns. A well-maintained machine operates efficiently and has a longer lifespan. Operators should follow a strict schedule for checking components. Ignoring simple issues can lead to costly repairs.

Support services can vary significantly. Some manufacturers offer 24/7 support, which can be a lifesaver. Quick assistance minimizes downtime. However, not all services are equal. Some support teams lack expertise. It's important to research the service quality before making a purchase.

Training for your staff is often overlooked. Proper training reduces the chances of operator errors. Sometimes, operators may skip essential protocols. This can lead to accidents or machine damage. Investing in comprehensive training is wise and necessary for smooth operations.

Related Posts

-

How to Choose the Right Plastic Molding Machine for Your Production Needs

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing

-

10 Essential Tips for Choosing the Right Molding Machine for Your Business

-

Top 10 Factors Affecting Injection Molding Estimate Costs You Should Know

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025