2026 How to Choose and Use Plastic Profiles Effectively?

In the evolving landscape of manufacturing, the choice of materials is crucial. Plastic profiles are increasingly popular due to their versatility and durability. John Smith, an industry expert, emphasizes, "Understanding the unique properties of plastic profiles is key to innovation." As companies seek to enhance their products, selecting the right plastic profile can significantly impact performance and longevity.

Navigating the world of plastic profiles involves more than just selecting a type. It requires understanding their applications in various industries. For instance, construction, automotive, and packaging all utilize these profiles differently. Each application demands specific characteristics from the materials used. This can sometimes lead to confusion and misjudgment in selection.

Mistakes can happen when choosing plastic profiles, particularly if the specific needs of a project are overlooked. It's essential to carefully assess the requirements. Deep reflection on the intended use can reveal better options. Plastic profiles can be effective but also carry risks if not selected wisely. Therefore, informed decisions based on industry knowledge are vital for optimal results.

Understanding Plastic Profiles: Types and Applications

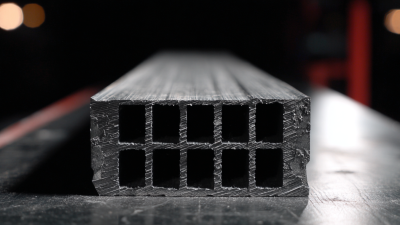

Understanding plastic profiles is crucial for various applications, including construction, automotive, and packaging. There are multiple types of plastic profiles, such as extruded, molded, and thermoformed ones. Each type has unique properties that suit specific uses. For example, extruded profiles are commonly used in windows and doors, while molded profiles serve effectively as connectors in various assemblies. According to industry reports, the global plastic profile market is expected to reach $30 billion by 2026, reflecting a steady growth of 4% annually.

Choosing the right type of plastic profile can be challenging. Consider application requirements such as durability and flexibility. Knowing the product's thermal stability and chemical resistance is essential. Remember, not every plastic profile fits every need. Sometimes, unanticipated issues may arise, like warping or brittleness. Evaluate the profiles in real-world conditions before making a choice.

Tips: Always test samples. Assess different profiles to gauge performance before purchase. Consult with experts for tailored advice. Regularly review your selections to adapt to new advancements in plastic technology. An informed approach minimizes risks and enhances project success.

Plastic Profiles Types and Their Applications

Factors to Consider When Choosing Plastic Profiles

When selecting plastic profiles, several factors come into play. Consider the intended application first. Different profiles suit various uses. For instance, structural components require sturdiness. Reports indicate that over 50% of plastic failures arise from inadequate material selection.

Next, think about environmental resistance. Some plastics perform well under UV light, while others don’t. The choice largely affects longevity. According to market analysis, UV-resistant materials can extend product lifespan by up to 30%. This aspect can’t be overlooked in outdoor applications.

Compatibility with other materials is crucial too. Some plastics bond poorly with metals or other plastics. This can lead to functional issues. Evaluating the end-use environment is necessary. Many users overlook this detail, leading to costly failures. A comprehensive understanding of these factors can significantly boost effectiveness.

Techniques for Effective Installation of Plastic Profiles

When installing plastic profiles, proper techniques can significantly enhance the overall result. Start by ensuring your workspace is clean and well-organized. A cluttered area can lead to mistakes and accidents. Check all your tools beforehand; using the wrong tool can damage the profiles.

One of the most important steps is measuring accurately. Use a tape measure to get precise dimensions. Mark these measurements clearly on your plastic profiles. Keep a level handy to ensure everything is straight. If the profiles are not aligned, it can lead to gaps or uneven surfaces. Mistakes can be costly.

**Tips:** Always dry-fit the pieces before finalizing the installation. This practice allows you to see how they fit together. It’s wise to adjust as necessary at this stage, rather than after applying adhesive. Another tip is to consider temperature. Plastic can expand or contract with heat. Installing in a stable temperature can prevent future issues.

Remember, even with careful planning, things may not go as expected. Brushing off minor imperfections might seem easier but can haunt you later. Reflect on each installation and learn from any mishaps for better results in the future.

Maintenance Tips for Longevity of Plastic Profiles

Maintaining plastic profiles is crucial for their longevity. Regular cleaning is essential. A simple mixture of mild soap and water works well. Use a soft cloth or sponge to avoid scratching the surface. Rinse thoroughly to remove any residue. Ensure the profiles are dry before storage or reinstallation.

Inspecting for damage is important. Look for cracks, discoloration, or warping. These issues can worsen over time if neglected. Consider applying a UV protectant to shield against sun damage. This can help maintain color and structural integrity. However, remember that this is not a permanent fix; periodic reapplication is necessary.

Storage conditions matter too. Keep plastic profiles in a cool, dry place. Extreme temperatures can lead to shrinkage or expansion. Stacking them improperly can cause warping. If possible, store them upright to avoid pressure points. A little foresight can prevent costly replacements.

2026 How to Choose and Use Plastic Profiles Effectively? - Maintenance Tips for Longevity of Plastic Profiles

| Dimension | Material Type | Application | Maintenance Tip | Expected Lifespan |

|---|---|---|---|---|

| 10 mm x 20 mm | PVC | Window Frames | Regular cleaning with mild soap | 20 years |

| 15 mm x 30 mm | Polypropylene | Furniture Components | Avoid exposure to extreme heat | 15 years |

| 5 mm x 10 mm | Acrylic | Display Cases | Use a soft cloth, avoid abrasives | 10 years |

| 20 mm x 40 mm | Polycarbonate | Greenhouses | Inspect for UV damage regularly | 25 years |

| 25 mm x 50 mm | PETG | Signage | Avoid scratching with hard objects | 12 years |

Innovative Uses of Plastic Profiles in Various Industries

Plastic profiles are transforming various industries with their innovative applications. In construction, for instance, lightweight plastic profiles are increasingly replacing traditional materials. According to a report by MarketsandMarkets, the global plastic profile market is projected to reach $120 billion by 2026. This growth reflects the material's versatility and cost-effectiveness.

In the automotive sector, plastic profiles contribute to reducing vehicle weight and improving fuel efficiency. A study by the American Chemistry Council found that replacing metal components with plastic can reduce weight by up to 20%. This shift not only enhances performance but also supports sustainability goals.

**Tip:** When selecting plastic profiles, consider their thermal resistance and load-bearing capacities. Assessing these factors can make a significant difference in efficiency.

Plastic profiles are also gaining attention in the packaging industry. They enable creative designs and functionalities, improving product protection. However, it's important to be mindful of the environmental impact of plastic waste. Striking a balance between innovation and sustainability is essential.

**Tip:** Explore biodegradable plastic alternatives. They may offer new possibilities while reducing your carbon footprint.

Related Posts

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Why Injection Molding is Essential for Modern Manufacturing Success

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

How to Choose the Right Plastic Molding Machine for Your Production Needs

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry