Top 10 Tips for Choosing the Best Plastic Injection Molding Machine

Choosing the right plastic injection molding machine is a critical decision for manufacturers seeking to optimize production efficiency and product quality. With a myriad of options available in the market, the selection process can be overwhelming. Understanding the key factors that influence this choice is essential not only for ensuring smooth operations but also for achieving long-term business success. From assessing the machine's specifications to considering the technical support and maintenance services, each aspect plays a vital role in the overall effectiveness of plastic injection molding.

As the demand for high-quality plastic components continues to rise across various industries, investing in the right machinery becomes increasingly important. An appropriate plastic injection molding machine can significantly enhance productivity while minimizing waste, leading to better economic returns. In this guide, we will explore the top ten tips that can help you navigate the complexities of selecting the best plastic injection molding machine tailored to your specific needs, ultimately ensuring that your manufacturing processes are efficient, reliable, and cost-effective.

Understanding Plastic Injection Molding Machines and Their Applications

Plastic injection molding is a widely utilized manufacturing process that allows for the creation of complex plastic components with high precision and repeatability. This technique involves melting plastic resin and injecting it into a mold where it cools and solidifies into the desired shape. The versatility of plastic injection molding makes it suitable for a plethora of applications, ranging from automotive parts and consumer goods to medical devices and packaging solutions. Understanding the range of materials and potential designs that can be achieved with injection molding is crucial for manufacturers seeking to innovate and reduce production costs.

The applications of plastic injection molding are vast and ever-expanding. Industries benefit from the ability to create lightweight yet durable products, enabling advancements in design and functionality. In the automotive sector, for instance, injection-molded components contribute to the manufacturing of lighter vehicles, improving fuel efficiency and performance. Additionally, in the medical field, the demand for precision and compliance with strict regulations emphasizes the necessity of high-quality molding processes. By grasping these applications, companies can better align their production strategies and machinery choices to meet market demands effectively and enhance their competitive edge.

Key Factors to Consider When Selecting an Injection Molding Machine

When selecting an injection molding machine, several key factors come into play to ensure optimal performance and efficiency.

First and foremost, it is essential to consider the machine's clamping force, which determines the maximum size and thickness of the parts that can be molded.

An adequate clamping force is crucial for preventing defects and ensuring that the finished products meet quality standards.

Additionally, the injection unit's design, including its volume and pressure capabilities, must align with the specific materials you intend to process, which affects both the quality of the output and the cycle time.

Another critical factor is the machine's energy efficiency. Modern injection molding machines incorporate advanced technologies that significantly reduce energy consumption while maintaining reliable output.

This efficiency can lead to lower operating costs and a reduced environmental footprint. Furthermore, explore the ease of operation and maintenance features of the machine, as user-friendly controls and accessible design can save time and resources in the long run.

Overall, evaluating these key factors will help you make an informed decision, ensuring that the selected injection molding machine meets your production requirements effectively.

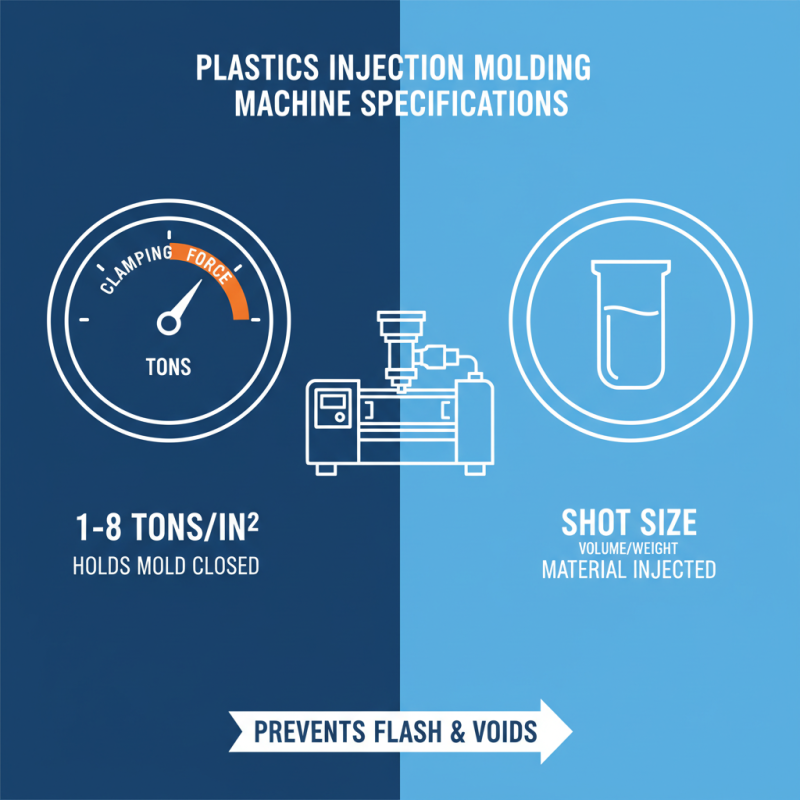

Evaluating Machine Specifications: Clamping Force and Shot Size

When evaluating plastic injection molding machines, two critical specifications to consider are clamping force and shot size. Clamping force, measured in tons, is essential for holding the mold together during the injection process. According to industry reports, the required clamping force often ranges from 1 to 8 tons per square inch of projected area, depending on the material and part thickness. For instance, a part with a higher injection pressure or complex geometries may necessitate a machine with a substantially higher clamping force to prevent the mold from separating during operation.

Shot size is another vital specification, as it determines the volume of plastic that can be injected per cycle. The shot size must align with the part volume to ensure consistency and quality in production. Industry standards suggest that the shot size should typically be 1.5 to 2 times the weight of the final part to accommodate for material flow and shrinkage during cooling. For example, if the target part weighs 50 grams, selecting a machine with a shot size capacity of around 75 to 100 grams would facilitate optimal performance. Balancing these specifications is crucial for achieving efficiency, minimizing waste, and ensuring dimensional accuracy in plastic injection molding.

Assessing Energy Efficiency and Operational Costs of Injection Machines

When selecting a plastic injection molding machine, evaluating energy efficiency and operational costs is crucial for maximizing productivity and minimizing expenses. Energy consumption is one of the key factors that directly impacts the total cost of ownership of the machine. Opt for machines that incorporate advanced technology, such as servo motors or hybrid systems, which can significantly reduce energy use during the molding process. These machines not only consume less power during idle times but also optimize energy flow during operation, leading to lower utility bills and a smaller carbon footprint.

In addition to energy efficiency, it’s essential to consider the overall operational costs associated with maintenance and downtime. Machines that are easier to service and maintain can help in reducing unexpected downtime, which translates to a more consistent production schedule. Furthermore, invest in a machine that offers a balance between initial capital investment and long-term savings. This strategy will allow for a more sustainable operational model, ensuring that the benefits of energy efficiency and lower operational costs lead to a favorable return on investment. Analyzing the total cost of ownership over the lifespan of the machine will provide a clearer picture of its economic viability.

Energy Efficiency and Operational Costs of Injection Molding Machines

The Importance of Manufacturer Reputation and Support Services

When selecting a plastic injection molding machine, understanding the reputation of the manufacturer is crucial. A manufacturer's credibility is often reflected in industry reviews and customer testimonials, which can be found in comprehensive reports such as the "Global Plastic Injection Molding Machine Market Report." According to the report, companies known for robust post-sale support and reliability consistently outperform their competition, showcasing the importance of ongoing customer engagement and technical assistance in enhancing machine longevity and performance.

One key tip is to prioritize manufacturers that offer extensive support services, including technical training and responsive customer care. For instance, organizations reporting high satisfaction levels typically evaluate the responsiveness of their suppliers, highlighting the direct correlation between strong support services and efficient production operations. A supportive partner can provide immediate assistance during critical downtimes, which not only minimizes disruption but also contributes to higher overall productivity.

Furthermore, inquire about the manufacturer's history and track record within the industry. Established firms boast a proven history of innovation and reliability, often backed by consistent investments in technology and research. This is reflected in data showing that manufacturers with a longer operational history tend to show lower failure rates in machinery, emphasizing the necessity of choosing a reputable source for your injection molding needs.

Related Posts

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

-

2025 Top 10 Innovations Revolutionizing the Injection Molding Process

-

Why Is Injection Molding the Best Choice for Prototyping and Production