10 Essential Tips for Choosing the Right Molding Machine for Your Business

In the manufacturing industry, the choice of equipment can significantly impact productivity and cost-efficiency. One of the critical pieces of machinery in this sector is the molding machine, which plays a vital role in the production of various plastic and metal products. According to recent industry reports, the global injection molding machine market is projected to reach USD 12.15 billion by 2025, growing at a CAGR of 5.7% during the forecast period. This trend highlights the increasing demand for advanced molding solutions that improve production capabilities and reduce waste.

Selecting the right molding machine for your business involves a strategic approach, as the wrong choice can lead to inefficiencies and increased operational costs. Factors such as machine size, technology, and energy consumption must be carefully considered. Research indicates that businesses that optimize their equipment selection can see productivity gains of up to 30%, thereby enhancing their competitive edge. With the development of new technologies and materials, taking the time to analyze your specific requirements will ensure that you invest in a molding machine that aligns with your production goals and helps propel your business forward.

Understanding Different Types of Molding Machines Available in the Market

When it comes to selecting a molding machine for your business, understanding the different types available is crucial. Molding machines can be categorized primarily into injection molding, blow molding, and compression molding. According to a recent industry report by MarketsandMarkets, the global injection molding machine market is expected to reach $13.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 3.7%. This highlights the growing demand for efficient and versatile manufacturing solutions.

Tips for choosing the right machine include evaluating your production volume needs. High-volume production might necessitate a more robust injection molding machine, while lower volumes may benefit from simpler, more cost-effective options. Additionally, consider the material compatibility of the machine. For instance, some machines are particularly suited for thermoplastics or elastomers, while others are designed specifically for glass-filled or other specialized materials.

Furthermore, automation is a key factor in modern molding processes. As indicated by the International Federation of Robotics, the adoption of industrial robots in manufacturing has been rising, with projections estimating 1.7 million new industrial robots will be deployed by 2025. This integration can enhance productivity and precision in molding operations. Always assess the level of automation in the machines you consider to ensure that they align with your operational goals and efficiency standards.

Evaluating Production Capacity and Efficiency for Your Business Needs

When selecting a molding machine for your business, one of the most critical factors to consider is its production capacity and efficiency. According to a report by Grand View Research, the global market for injection molding machines is projected to reach $11.2 billion by 2025, with a significant focus on efficiency-enhancing technologies. Businesses seeking to optimize their production processes must ensure that the machine they choose can meet their specific output requirements. Analyzing the machine's cycle time, maximum clamping force, and shot size are essential in determining if it aligns with your production goals.

In addition to raw capacity, the efficiency of a molding machine can significantly impact overall operational costs. A study from Research and Markets indicated that adopting energy-efficient machinery can reduce production costs by up to 30%. Features such as advanced control systems, which allow for real-time adjustments, can lead to reduced scrap rates and lower energy consumption. Therefore, when evaluating potential molding machines, it's crucial to consider not just the initial purchase price but also the long-term savings associated with efficiency. A thorough assessment of these aspects will ensure that your business is well-equipped to meet both current demand and future growth.

Assessing the Impact of Machine Precision on Product Quality

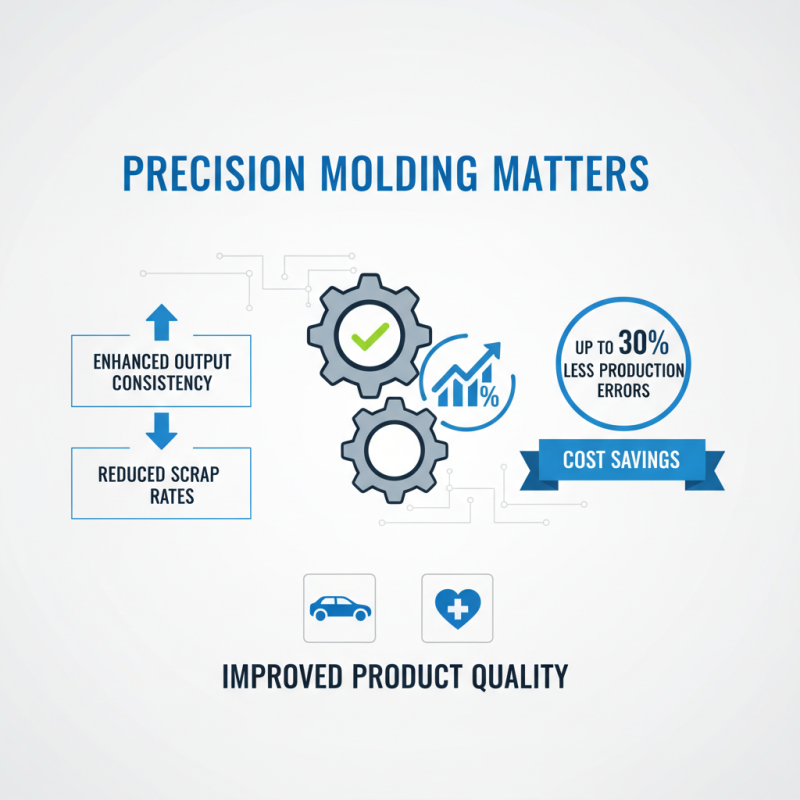

When selecting the right molding machine for your business, understanding the impact of machine precision on product quality is critical. High-precision molding machines often lead to enhanced output consistency and reduced scrap rates. According to a report from the International Journal of Advanced Manufacturing Technology, leveraging machines with precision capabilities can decrease production errors by as much as 30%, ultimately leading to significant cost savings. The report highlights that even a marginal improvement in dimensional accuracy can result in better fit and functionality of the final products, which is paramount in industries such as automotive and medical device manufacturing.

Another essential aspect to consider is the effect of precision on the overall efficiency of the production process. A survey conducted by the Society of Plastics Engineers found that manufacturers using high-precision molding technology reported a 25% increase in throughput compared to those using standard machinery. This increase in efficiency not only maximizes productivity but also accelerates delivery times, providing businesses with a competitive edge in the market. By investing in high-precision molding machines, organizations can ensure that they meet stringent quality standards while optimizing their operational processes, ultimately enhancing customer satisfaction and loyalty.

Considering Energy Consumption and Operational Costs in Molding Machines

When selecting a molding machine for your business, it is crucial to consider not only performance and capacity but also factors like energy consumption and operational costs. According to a report by the International Energy Agency, manufacturing processes account for over one-third of global energy use, with molding operations often representing a significant portion of these costs. Therefore, investing in energy-efficient machinery can lead to substantial long-term savings and lower carbon emissions, aligning with both financial and environmental sustainability goals.

Operational costs encompass various aspects, including maintenance, labor, and energy consumption. A study by the Plastics Industry Association highlights that energy costs can contribute up to 30% of the total operational expenses in molding processes. By opting for machines that utilize innovative technologies—such as servomotors or advanced control systems—businesses can improve their energy efficiency by up to 50%, thereby reducing overall operational expenditures while maintaining high throughput. Additionally, facilities that invest in energy audits and performance monitoring can track their energy consumption more effectively, ensuring continuous improvements and strategic decision-making in machinery investment.

Analyzing Vendor Support and Maintenance Services for Long-term Success

When selecting the right molding machine for your business, one of the most critical factors to consider is the level of vendor support and maintenance services they offer. A reliable vendor should provide comprehensive support throughout the life cycle of the machine, including installation, training, and ongoing maintenance. This support ensures that your team can operate the equipment safely and efficiently, minimizing downtime and maximizing productivity. Clear communication and prompt assistance from the vendor can significantly impact your operations, especially when unexpected challenges arise.

Moreover, the availability of maintenance services plays a crucial role in long-term success. Regular maintenance not only prolongs the lifespan of your molding machine but also enhances its performance and efficiency. A vendor offering robust maintenance plans can help in anticipating potential issues and addressing them proactively. It’s essential to evaluate the vendor’s response time and flexibility in accommodating your maintenance needs. Additionally, inquire about the availability of spare parts and the overall quality of their customer service, as these factors will deeply influence your operational continuity and profitability.

Vendor Support and Maintenance Services Rating

Related Posts

-

How to Choose the Right Plastic Molding Machine for Your Production Needs

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing

-

Top 10 Benefits of Rubber Injection Molding for Your Manufacturing Needs

-

Understanding the Different Types of Plastic Extruders and Their Applications

-

Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting

-

How to Create High Quality Injection Molded Parts in 2025