Top 10 Factors Affecting Injection Molding Estimate Costs You Should Know

The injection molding industry plays a pivotal role in manufacturing, with estimates indicating a market size of over $13 billion in the United States alone as of 2023. As companies increasingly rely on injection molding for producing high-quality components efficiently, understanding the costs associated with an "injection molding estimate" becomes essential. According to industry expert Dr. Emily Carter, "Accurate estimates are not just a matter of cost; they are crucial to the project’s success and timely delivery." Her insights underline the importance of considering various factors that can significantly impact overall manufacturing costs.

Numerous variables affect the final pricing of an injection molding estimate, ranging from material selection and design complexity to production volume and lead time. Industry reports suggest that approximately 30% of the total cost can be attributed to the choice of materials, making it a prime consideration for manufacturers. Additionally, as advancements in technology and automation continue to evolve, keeping abreast of these factors can lead to more precise estimates and better project outcomes. Understanding these dynamics not only aids in budget planning but also enhances competitiveness in a rapidly changing market.

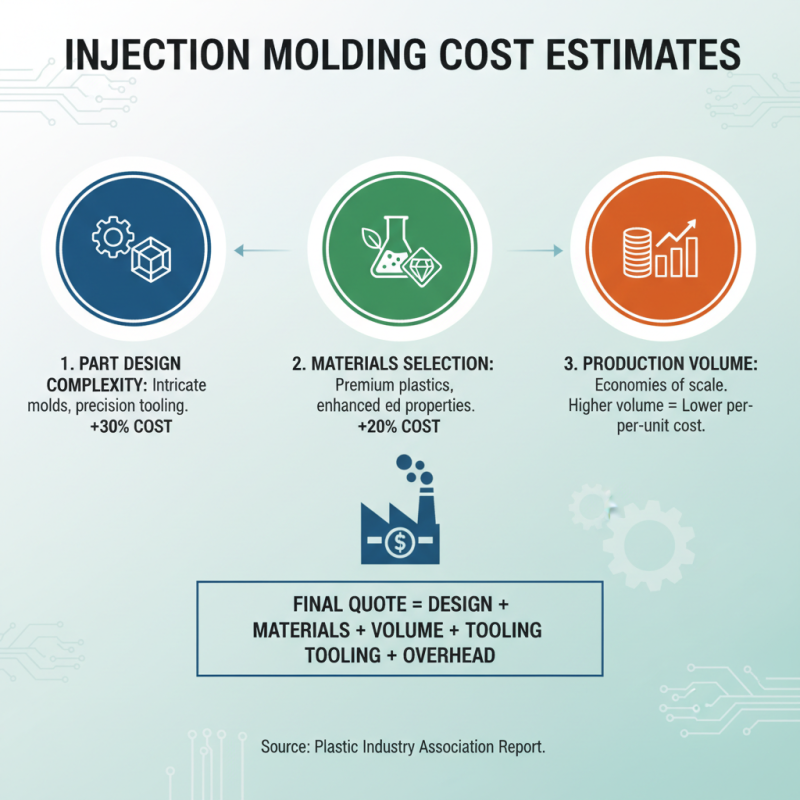

Understanding Injection Molding Cost Estimates

Understanding Injection Molding Cost Estimates involves several critical factors that directly influence the final quote for projects. One of the foremost components is the complexity of the part design; intricate designs require advanced tooling and more precision during the molding process, which can significantly increase costs. According to a report by the Plastic Industry Association, design complexity can multiply production costs by up to 30%. Moreover, materials selection plays a crucial role; premium materials may enhance performance but at a premium cost, potentially raising estimates by 20% or more.

Another vital aspect is the quantity of parts being produced. Typically, high-volume production benefits from economies of scale, lowering the overall per-unit cost. However, lower production runs can lead to higher costs per unit due to fixed overhead expenses spread across fewer parts. Additionally, tooling costs must also be factored in; specialized molds can cost thousands of dollars, impacting the initial estimate significantly.

Tips: When seeking cost estimates, it is advisable to communicate clearly with your vendor about design specifications and material preferences upfront. Transparency regarding project timelines can also lead to more accurate quotes and help identify any potential cost-saving strategies. Consider engaging in a detailed cost breakdown discussion—this can illuminate areas where compromises might be made without sacrificing quality.

Material Selection and Its Impact on Costs

Material selection is a critical factor in the cost estimation of injection molding projects. Different materials possess unique properties, which can significantly influence both the production process and final product performance. For instance, premium polymers may offer superior durability and aesthetic appeal, but their higher price points can increase overall project costs. Conversely, opting for more economical materials could lead to savings but may compromise on strength or quality, ultimately affecting customer satisfaction and marketability.

In addition to the raw material costs, the choice of material also impacts the processing conditions required during injection molding. Certain materials necessitate specialized equipment or processing techniques, which can further inflate expenses. For example, materials that require higher injection temperatures or longer cooling times may lead to increased energy consumption and longer cycle times, resulting in reduced production efficiency. Therefore, making informed decisions regarding material selection not only affects the upfront costs but also plays a significant role in the long-term profitability of injection molding operations.

Top 10 Factors Affecting Injection Molding Estimate Costs

This bar chart illustrates the estimated cost impact of various factors affecting injection molding estimates. Material selection stands out as the most significant factor, comprising 25% of the total cost considerations.

Labor and Overhead Considerations in Injection Molding

Labor and overhead considerations play a crucial role in determining the overall costs of injection molding projects. Labor costs include not only the wages of employees directly involved in the production process but also the training, benefits, and potential overtime that may arise during high-demand periods. Skilled labor is often required for setup, monitoring, and maintenance of machinery, adding an additional layer of cost. As the demand for precision and quality in molded parts increases, so does the need for experienced personnel, which can further elevate labor expenses.

Overhead costs encompass all indirect expenses associated with the injection molding process, such as utilities, equipment maintenance, facility lease, and administrative expenses. These costs can fluctuate based on the operational efficiency of the facility and the technology employed. For instance, a factory utilizing advanced machinery may incur higher initial capital expenditures but potentially lower operational costs due to efficiency gains and reduced manual labor requirements. Understanding and accurately estimating these labor and overhead factors is essential for manufacturers, as they significantly influence the pricing structure and profitability of injection molding projects.

Tooling and Setup Expenses in Injection Molding Projects

Tooling and setup expenses are critical components in the cost estimation of injection molding projects. The tooling phase involves the creation of molds, which are the backbone of the injection molding process. These molds are typically made from durable materials like steel or aluminum, and their design reflects the complexity and precision required for the final product. The initial investment in high-quality tooling can be substantial, but it is essential for achieving the desired finished product with minimal defects. Factors such as mold complexity, size, and required features significantly influence the overall tooling costs.

In addition to mold construction, setup expenses also contribute to the initial costs of an injection molding project. Setup involves preparing the machine, adjusting parameters, and performing trial runs to ensure everything functions smoothly before full production begins. This phase can require specialized labor and extensive testing, which may lead to additional costs. The efficiency of the setup process can also affect lead times and production schedules, making it a vital consideration in project planning. Overall, understanding the implications of tooling and setup expenses is paramount for accurately estimating the total costs associated with an injection molding project.

Part Complexity and Its Effect on Production Costs

Part complexity plays a crucial role in determining the costs associated with injection molding. When designing a product, factors such as intricate shapes, tight tolerances, and varied wall thickness can significantly influence the manufacturing process. More complex parts often require specialized tooling and more advanced production techniques, which can drive up initial expenses. The intricacy of a design not only affects the mold-making process but also influences cycle times, leading to longer production runs and increased labor costs.

Furthermore, part complexity can impact material selection and waste generation. Complex designs may necessitate the use of higher-grade materials or additional processing steps to ensure the final product meets quality standards. This could result in increased waste if the production process is not optimized, further adding to overall costs. Therefore, careful consideration of part complexity during the design phase is essential, as it directly correlates to the efficiency of the manufacturing process and the final cost of injection molding. By balancing design intricacy with production capabilities, businesses can better manage expenses and achieve economical outcomes.

Top 10 Factors Affecting Injection Molding Estimate Costs

| Factor | Description | Impact on Costs (%) |

|---|---|---|

| Part Complexity | Increased geometrical features and intricate designs lead to higher production costs due to longer cycle times. | 30% |

| Material Type | Different materials have varying costs, affecting the overall estimate. | 20% |

| Tooling Costs | High precision and durability in mold making result in elevated tooling expenses. | 25% |

| Production Volume | High volume orders typically reduce per-unit costs due to economies of scale. | 15% |

| Lead Times | Urgent projects may incur additional costs to expedite the production process. | 10% |

| Finish Quality | Higher finish quality requirements can increase processing times and costs. | 18% |

| Rework Needs | Parts that require rework due to defects can significantly increase overall costs. | 12% |

| Design Changes | Frequent changes in design can lead to delays and extra costs in production. | 22% |

| Regulatory Compliance | Meeting industry standards and regulations can add additional costs. | 17% |

| Machine Maintenance | Well-maintained machines reduce breakdowns, impacting overall production cost. | 8% |

Related Posts

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development

-

2025 Top 10 Innovations Revolutionizing the Injection Molding Process

-

Top 10 Tips for Successful Prototype Injection Molding You Need to Know

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry