The Future of Injection Tooling in Sustainable Manufacturing Practices

The future of injection tooling in sustainable manufacturing practices is rapidly evolving as industries seek to minimize their environmental impact while maximizing efficiency. According to a report by the International Data Corporation (IDC), the global market for sustainable manufacturing was valued at approximately $1.24 trillion in 2021, with projections indicating a compound annual growth rate (CAGR) of 8.7% through 2027. As companies increasingly adopt eco-friendly practices, injection tooling emerges as a vital component in this transition, offering innovative solutions that enhance production processes and reduce waste.

By integrating advanced materials and technologies, such as bioplastics and energy-efficient machinery, the injection tooling sector is not only responding to regulatory demands but also aligning with consumer preferences for sustainable products. Therefore, it becomes essential to understand how injection tooling can drive the next wave of sustainable manufacturing and support the industry in achieving broader environmental goals.

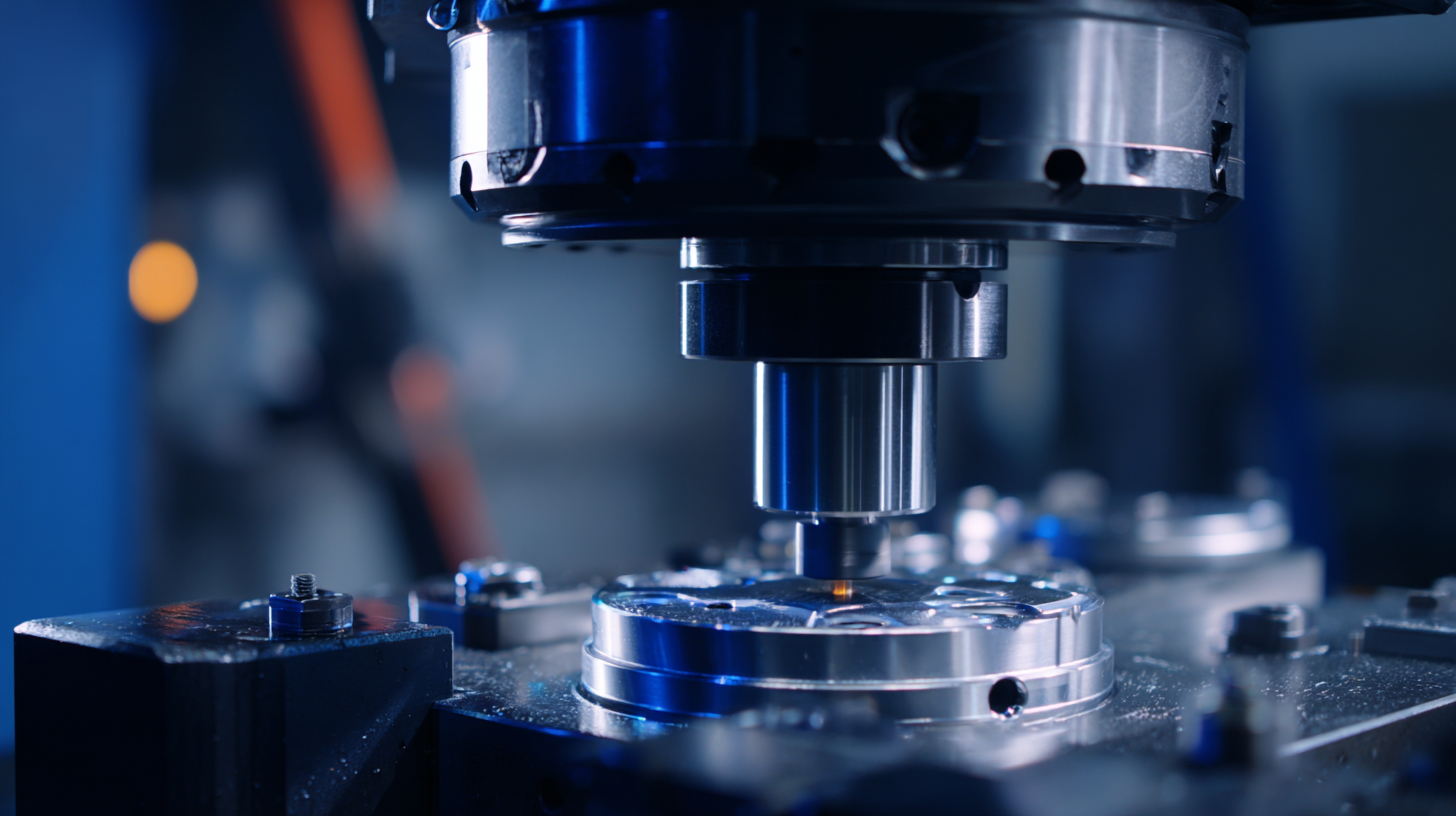

Emerging Technologies in Injection Tooling for Sustainable Manufacturing

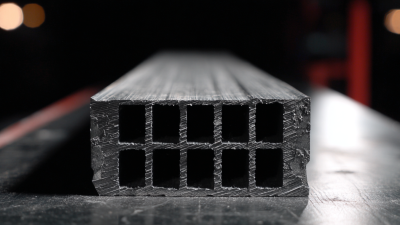

The injection tooling industry is at the forefront of sustainable manufacturing practices, largely due to emergent technologies revolutionizing the landscape. One key innovation is the development of biopolymers, which serve as environmentally friendly alternatives to traditional plastics. These materials not only reduce dependence on fossil fuels but also enhance the recyclability of products. Manufacturers are increasingly integrating biopolymer formulations into their tooling processes, which allows for producing sustainable components without compromising quality or durability.

Another significant advancement is the introduction of smart tooling and Industry 4.0 technologies. These systems leverage data analytics and automation to optimize production efficiency and minimize waste throughout the injection molding process. By employing predictive maintenance and real-time monitoring, businesses can significantly reduce downtime and resource consumption. This shift not only impacts the bottom line but also aligns with global sustainability goals, as fewer resources lead to a smaller environmental footprint. Together, these technologies are setting a new standard for sustainable practices in injection tooling, paving the way for a greener manufacturing future.

Integrating Digital Solutions into Injection Tooling Processes

The integration of digital solutions into injection tooling processes is poised to redefine sustainable manufacturing practices. Companies are increasingly adopting advanced technologies such as artificial intelligence and automation to enhance efficiency and precision in their operations. By leveraging digital tools, manufacturers can gain real-time visibility into tooling status and specifications, which allows for better control during production runs. This visibility is crucial for minimizing waste and improving resource management, aligning with sustainability goals.

Moreover, the digital transformation within injection tooling extends beyond mere efficiency. As organizations implement digital solutions, they are also addressing labor challenges and fostering an environment that empowers regional teams. This approach not only enhances productivity but also supports innovation and adaptability in meeting the demands of the evolving market, particularly in sectors like electric vehicle production. By embracing these technologies, manufacturers not only streamline their processes but also contribute to a more sustainable future in manufacturing.

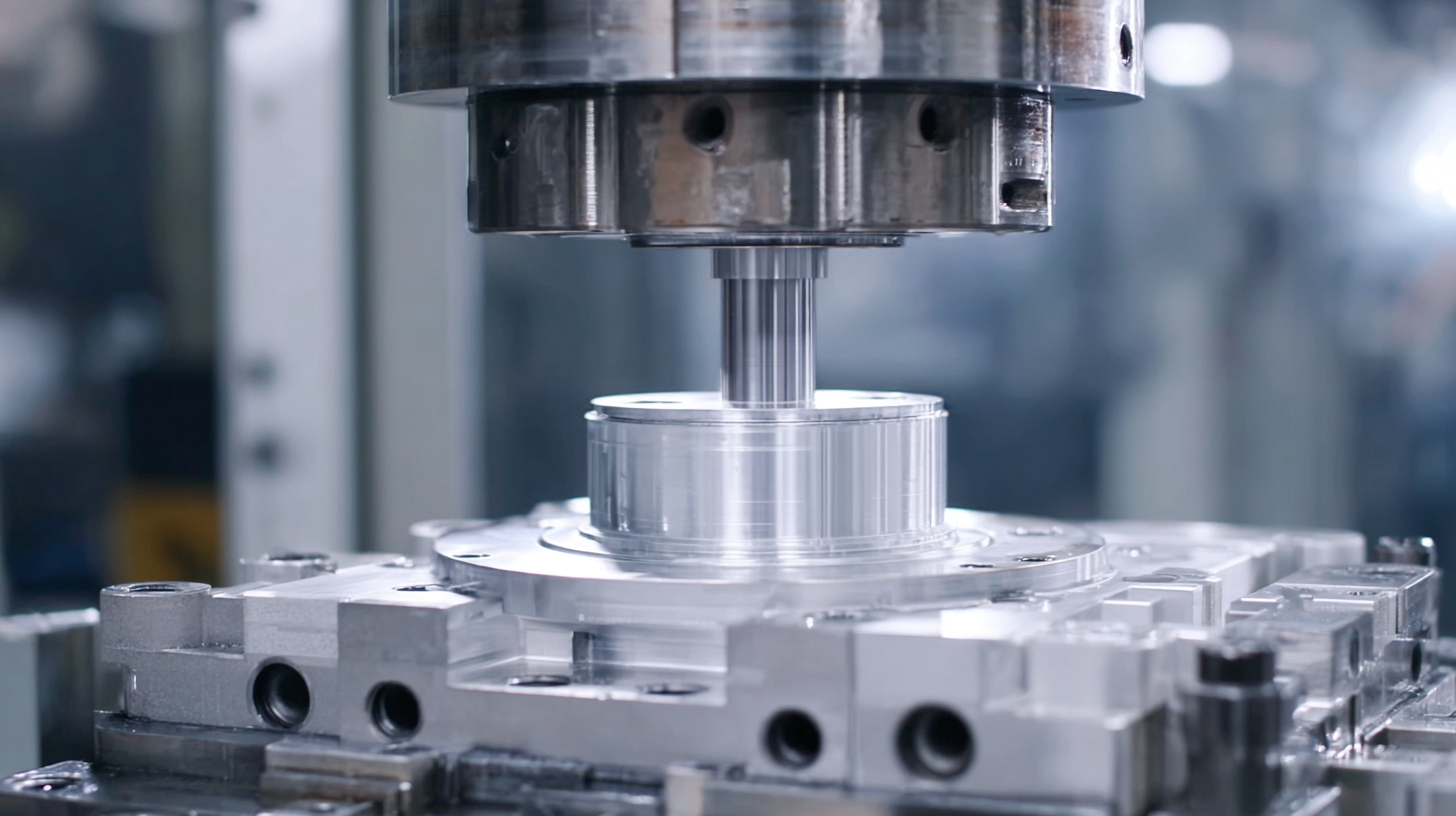

Evaluating the Environmental Impact of Injection Molding Techniques

Injection molding is a widely used manufacturing process that enables the production of complex parts efficiently. However, its environmental impact has become a focal point as industries increasingly pivot towards sustainability. According to a report by the Association of Plastics Recyclers, approximately 30% of produced plastic is recycled, highlighting the need for improved recycling rates and sustainable practices in injection molding.

Innovations in injection molding technology are making strides to minimize environmental footprints. One compelling advancement is the development of bio-based resins, which can reduce reliance on fossil fuels and lower greenhouse gas emissions. A study by the American Chemistry Council indicates that by incorporating biodegradable materials, manufacturers could cut carbon emissions by 50% in some applications. Additionally, the implementation of closed-loop systems in injection molding can lead to significant reductions in waste, promoting circular economy principles.

Moreover, energy-efficient machinery designed for injection molding operations is essential in decreasing energy consumption. According to the European Plastics Converters association, modern electric injection molding machines can consume up to 60% less energy compared to traditional hydraulic machines. This is a significant reduction that not only decreases operational costs but also aligns manufacturing practices with global sustainability goals. As the industry evolves, the emphasis on minimizing environmental impact will likely drive further innovations in injection tooling processes.

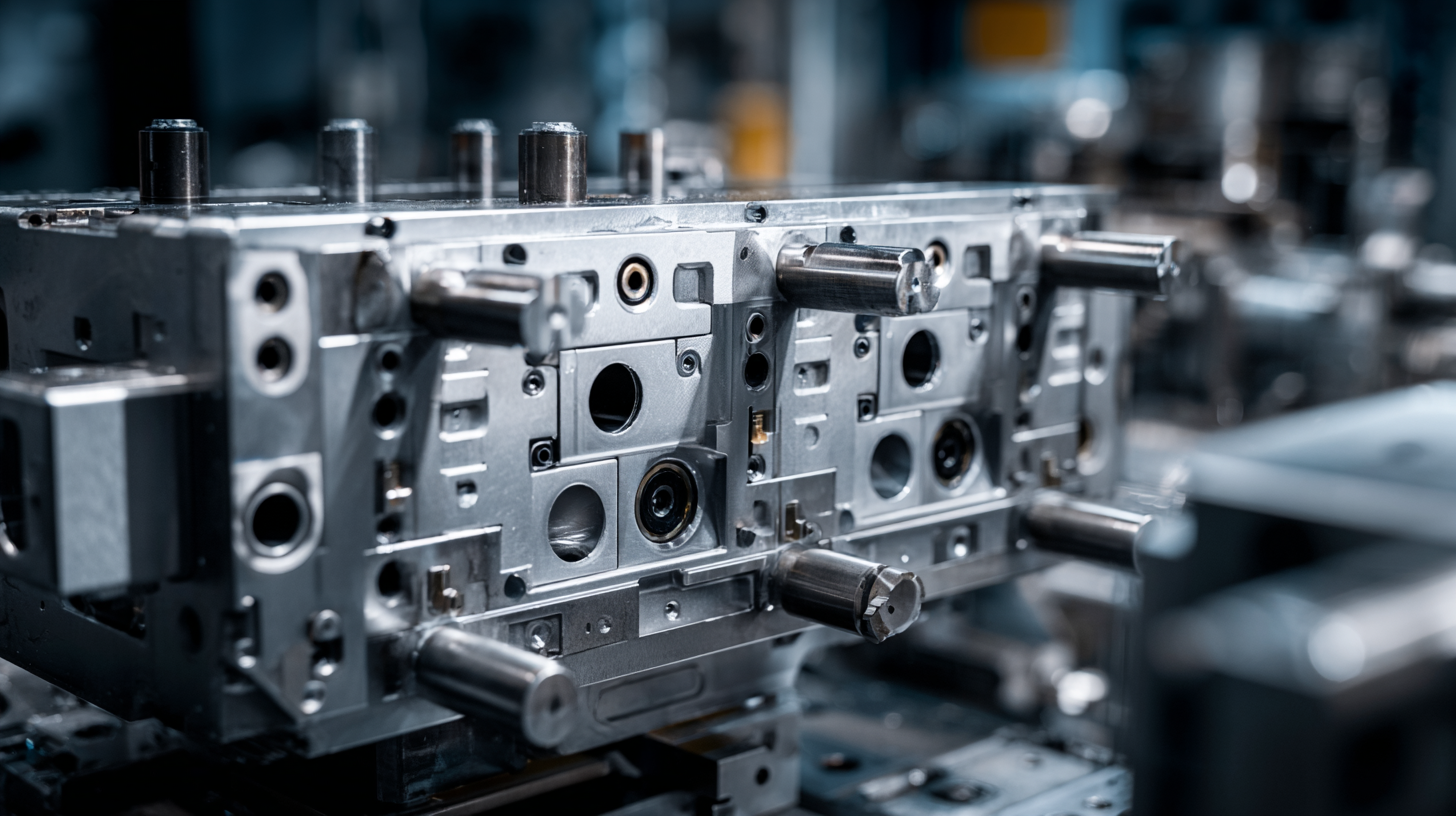

Best Practices for Reducing Waste in Injection Tooling Operations

In sustainable manufacturing practices, reducing waste in injection tooling operations is crucial for enhancing efficiency and minimizing environmental impact. Companies are increasingly exploring innovative approaches, such as the implementation of synthetic greases that improve die performance and reduce unplanned downtime. This switch not only optimizes machine longevity but also conserves resources by eliminating the need for frequent replacements and repairs, ultimately contributing to a more sustainable production cycle.

Moreover, advancements in automation technology play a vital role in waste reduction within injection molding processes. By leveraging autonomous algorithms, manufacturers can monitor part quality in real-time and promptly address any discrepancies, preventing excess material usage and rework. These advancements not only streamline operations but also significantly decrease waste generation, aligning with the overarching goal of sustainable manufacturing practices. As companies continue to invest in these technologies and best practices, the injection tooling sector will undoubtedly progress towards more sustainable and efficient operations.

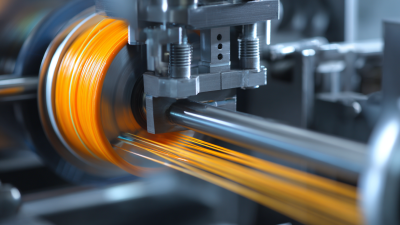

Future Trends: Automation and AI in Sustainable Injection Tooling

The injection tooling market is on a robust growth trajectory, with LIM and LSR injection molding machines projected to rise from $159.5 million in 2024 to $283.83 million by 2032, reflecting a noteworthy compound annual growth rate (CAGR) of 7.47%. This advancement in the industry is closely linked to the increasing integration of automation and artificial intelligence (AI) in sustainable manufacturing practices. As manufacturers look to enhance operational efficiency and reduce waste, the adoption of smart technology becomes essential for staying competitive in a rapidly evolving marketplace.

Moreover, businesses in regions like Hong Kong are pivoting towards smart manufacturing models amidst challenges such as rising labor costs and unpredictable market demands. The shift is fueled by the necessity for innovation in production processes, which are increasingly powered by AI-driven solutions. This transition not only addresses immediate economic pressures but also aligns with global trends aiming for greener and more efficient manufacturing practices. As the sector evolves, the synergy between sustainable practices and advanced automation is set to play a pivotal role in shaping the future landscape of injection tooling.

The Future of Injection Tooling in Sustainable Manufacturing Practices - Future Trends: Automation and AI in Sustainable Injection Tooling

| Trend | Description | Impact on Sustainability | Automation Level |

|---|---|---|---|

| Robotic Process Automation | Increasing use of robots for consistent and efficient injection molding. | Reduces material waste and enhances precision. | High |

| AI-Driven Quality Control | Utilization of AI algorithms to monitor and optimize process quality. | Minimizes defects and reduces rework, promoting resource efficiency. | Medium |

| Predictive Maintenance | Using machine learning to predict equipment failures before they happen. | Decreases downtime and conserves energy efficiency. | High |

| Sustainable Material Selection | Adoption of bioplastics and recycled materials in injection molding. | Lowers carbon footprint of production processes. | Low |

| Energy-Efficient Machinery | Integration of energy-efficient injection molding machines. | Significantly reduces energy consumption during production. | Medium |

Related Posts

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023