2025 Guide: How to Calculate Injection Molding Mold Costs Effectively

The injection molding industry continues to be a cornerstone of manufacturing, with the global market expected to reach $341.26 billion by 2025, according to recent market analysis reports. As manufacturers strive to optimize their production efficiency and minimize costs, understanding the intricacies of injection molding mold cost has become paramount. This specialized knowledge not only aids in budget planning but also in selecting the right materials and processes to ensure the best return on investment.

Effective calculation of injection molding mold costs involves a plethora of factors, ranging from material selection and mold design to production volume and maintenance considerations. Industry experts suggest that mold costs can account for up to 30% of the total manufacturing expenses for molded parts. Therefore, companies that leverage systematic approaches to analyze and forecast these costs can significantly enhance their competitive edge. Utilizing data-driven insights and benchmarks, manufacturers can navigate the complexities of injection molding mold cost, leading to more informed decisions and ultimately boosting profitability.

Understanding the Basics of Injection Molding Mold Costs

When it comes to calculating injection molding mold costs, it's essential to grasp the fundamental components that contribute to these expenses. The cost of a mold can vary significantly based on its complexity, size, and the materials used. According to the American Society of Plastic Engineers (ASPE), the average cost of an injection mold can range from $5,000 to over $100,000, depending on the part geometry and production volume required. More complex molds that incorporate advanced features like hot runner systems or multi-cavity designs can dramatically increase costs, sometimes exceeding $250,000.

Additionally, the lifecycle of mold costs must be taken into account. A study by the Society of Manufacturing Engineers (SME) highlights that nearly 60% of the total costs associated with injection molding relate to the mold itself, emphasizing the critical importance of accurate cost estimation during the design phase. Maintenance and potential modifications can further impact these costs, making it crucial for manufacturers to conduct a thorough cost analysis. Understanding these foundational aspects of injection molding mold costs enables businesses to make informed decisions that optimize both the quality and profitability of their production processes.

2025 Injection Molding Mold Costs Breakdown

Key Factors Influencing Mold Cost Calculations

When calculating injection molding mold costs, several key factors come into play that significantly influence the overall expenses. First and foremost, the complexity of the mold design is critical. Intricate designs require advanced engineering and more extensive machining, which can substantially increase labor and material costs. The number of cavities in the mold also affects pricing; more cavities generally lead to higher costs but can reduce the cost per part manufactured, creating a balance that needs careful consideration.

Another crucial factor is the choice of materials used for the mold itself. High-grade steel or aluminum can enhance the mold's longevity and performance but will also drive up initial costs. Additionally, the expected production volume plays a significant role; higher volume runs often justify the expense of more durable materials.

Lastly, factors like lead time and manufacturing location can impact pricing significantly, as shorter lead times may incur rush fees, and different regions may have varying labor costs. It's essential to evaluate all these factors to achieve an accurate calculation of mold costs and ensure a successful injection molding project.

Step-by-Step Guide to Estimating Production Expenses

When estimating production expenses for injection molding, it’s essential to break down the cost components systematically. Start by identifying the fixed costs, which include design, tooling, and setup expenses. The mold design is critical, as it directly impacts both quality and longevity, thus affecting long-term costs. Allocate a portion of these upfront costs over the expected production run to accurately reflect the per-part expense.

Next, consider variable costs that fluctuate based on production volume, such as raw materials and labor. Calculate material costs by determining the type and amount of resin needed for the projected production. Additionally, evaluate labor costs, not just for manufacturing but also for maintenance and quality assurance during the production process. By analyzing both fixed and variable costs, manufacturers can gain a comprehensive understanding of their material expenses, aiding in more effective budgeting and cost management for injection molding projects.

2025 Guide: How to Calculate Injection Molding Mold Costs Effectively

| Cost Component | Description | Estimated Cost ($) |

|---|---|---|

| Design Costs | Costs associated with the creation of the mold design | $3,000 |

| Material Costs | Cost of raw materials used for the mold | $2,500 |

| Machining Costs | Costs for machining and shaping the mold | $4,500 |

| Assembly Costs | Labor costs for assembling the mold components | $1,500 |

| Testing Costs | Costs incurred during the testing of the mold | $1,000 |

| Total Estimated Costs | Total of all aforementioned costs | $12,500 |

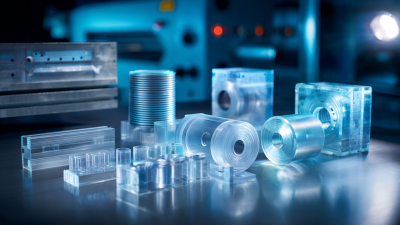

Comparing Different Mold Materials and Their Costs

When considering injection molding mold costs, one of the primary factors to evaluate is the choice of mold materials. Different materials can significantly impact the overall cost, durability, and production efficiency of molds. Common materials include aluminum, steel, and various specialized alloys.

Aluminum molds offer lower initial costs and faster production times, making them ideal for low-volume projects. However, they have a shorter lifespan compared to their steel counterparts and are less suited for high-volume production.

On the other hand, steel molds, while more expensive upfront, provide greater durability and longer service life, which can be advantageous for high-volume runs. The initial investment in steel molds may be offset by their extended operational lifespan and the ability to produce high-quality parts consistently.

Ultimately, the choice between aluminum and steel will depend on the specific requirements of the project, including the production volume and the desired quality of the final product. Understanding these dynamics is essential for effectively calculating injection molding costs and optimizing manufacturing processes.

Tips for Reducing Injection Molding Mold Costs Efficiently

When it comes to reducing injection molding mold costs, strategic planning and foresight are key. First, it is essential to choose the right materials. Opting for cost-effective yet durable materials can significantly decrease initial investment and maintenance costs. Consider using aluminum molds for shorter production runs, as they are less expensive and can be produced more rapidly compared to steel molds. Additionally, understanding the properties of different plastics can help in selecting materials that not only suit the product’s requirements but also contribute to overall cost savings.

Another crucial tip is to streamline the design process by employing design for manufacturability (DFM) principles. Simplifying the part design can lead to fewer complex features and consequently lower mold complexity. This not only reduces production time but also minimizes the necessity for extensive labor or machine time, further driving down costs. Collaborating closely with designers and engineers during the early stages can help identify potential cost-saving measures, ensuring that designs are optimized for efficient molding while maintaining quality standards.

Related Posts

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting

-

10 Essential Tips for Working with Injection Moldable Plastics

-

Exploring the Future of Rubber Injection Molding: Innovations and Applications in 2024

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry