Top 10 Tips for Injection Mold Design: Achieve Optimal Efficiency & Quality

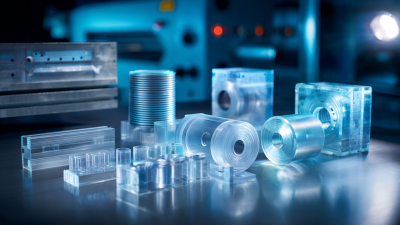

Injection mold design is a critical component in the manufacturing process, significantly influencing both the efficiency of production and the quality of the final product. In a world where precision and consistency are paramount, mastering the intricacies of injection mold design can lead to remarkable improvements in production outcomes. This guide presents the top 10 tips to achieve optimal efficiency and quality in your injection molding projects, addressing key considerations that every designer should keep in mind.

Effective injection mold design not only streamlines the manufacturing process but also helps in reducing costs and enhancing product performance. From material selection to mold maintenance, each aspect plays a vital role in ensuring that the molds operate at their best. As we explore these essential tips, you will gain insights into best practices that can elevate your injection mold design, making it both innovative and reliable. Whether you are a seasoned professional or new to the field, these strategies will empower you to refine your design approach and achieve superior results in your injection molding endeavors.

Key Principles of Injection Mold Design for Efficiency

Efficient injection mold design is crucial for producing high-quality parts while minimizing costs and production time. By adhering to key principles of design, manufacturers can enhance the overall efficiency of their molding processes. One essential tip is to prioritize the design of the mold cavity and core. Ensuring proper alignment and fitting between these components can significantly reduce the chances of defects during production, ultimately leading to better product quality.

Another important aspect is incorporating draft angles in the mold design. Draft angles facilitate the easy ejection of parts from the mold, preventing damage and ensuring a smoother cycle time. It is advisable to include a minimum draft of 1 to 2 degrees, depending on the material being processed. Additionally, optimizing cooling channels is essential for maintaining consistent temperatures throughout the mold, which helps in achieving uniformity in the produced parts and reducing cycle times.

Lastly, consider material selection and thickness variations to enhance durability while maintaining weight efficiency. Using advanced materials can increase the mold lifespan and reduce maintenance costs. Integrating these principles into the design process will lead to improved efficiency and product quality, setting the foundation for successful injection molding operations.

Material Selection: Choosing the Right Plastics for Your Project

Choosing the right plastics for your injection molding project is crucial to achieving optimal efficiency and product quality. The selection process begins with understanding the specific requirements of your application, including mechanical properties, thermal stability, and environmental considerations. For instance, if the final product demands high strength and durability, engineering plastics like polycarbonate or nylon may be suitable choices due to their superior impact resistance. Conversely, if cost-effectiveness is a primary concern, standard thermoplastics such as polypropylene or polyethylene can provide a balance of performance and affordability.

Another essential factor in material selection is processing characteristics. Different plastics have varying melting temperatures and flow properties, influencing the mold design and cycle time during production. It’s important to consider these parameters to ensure smooth material flow and avoid issues such as warping or incomplete filling of the mold cavity. Additionally, compatibility with additives, colorants, or surface treatments should be evaluated to meet aesthetic and functional requirements. By carefully assessing these criteria, designers can make informed decisions that enhance both the manufacturing process and the end product's performance, ultimately leading to increased customer satisfaction.

Top 10 Tips for Injection Mold Design: Achieve Optimal Efficiency & Quality - Material Selection: Choosing the Right Plastics for Your Project

| Material Type | Properties | Common Applications | Cost (per kg) |

|---|---|---|---|

| Polypropylene (PP) | Lightweight, chemical resistant, good fatigue resistance | Containers, automotive parts, textiles | $1.20 |

| Acrylonitrile Butadiene Styrene (ABS) | Durable, impact resistant, good heat resistance | Toys, electronic housings, automotive interior parts | $2.50 |

| Polyethylene (PE) | Flexible, low-density, chemical resistant | Plastic bags, bottles, containers | $1.00 |

| Polycarbonate (PC) | High impact resistance, optical clarity, heat resistant | Safety glasses, automotive components, lighting | $3.00 |

| Nylon (Polyamide) | High strength, wear resistant, good chemical resistance | Automotive parts, consumer goods, industrial components | $2.00 |

| Polystyrene (PS) | Rigid, good insulation properties, easy to mold | Packaging, disposable cutlery, insulation | $1.50 |

| Thermoplastic Elastomer (TPE) | Flexible, rubber-like properties, durable | Seals, gaskets, grips | $4.00 |

| Polyurethane (PU) | Versatile, abrasion resistant, flexible or rigid | Foams, elastomers, coatings | $3.50 |

| Polyvinyl Chloride (PVC) | Durable, chemical resistant, low maintenance | Pipes, medical devices, electronics | $1.80 |

| Polyethylene Terephthalate (PET) | High strength, good gas barrier, recyclable | Bottles, food containers, automotive parts | $2.20 |

Optimal Cooling System Design for Enhanced Production Speed

An optimal cooling system design is crucial in injection mold design, significantly influencing production speed and overall efficiency. The cooling phase in the injection molding process directly affects cycle time and part quality. By implementing strategically placed cooling channels, manufacturers can enhance heat dissipation, allowing the molded material to solidify uniformly and quickly. This not only reduces the time products spend in the mold, but also minimizes the risk of defects caused by uneven cooling.

Moreover, utilizing advanced materials for cooling systems can further improve thermal conductivity, thereby enhancing the cooling process. Incorporating temperature monitoring systems allows for real-time adjustments, ensuring that the cooling conditions remain optimal throughout the production cycle. Consideration of factors such as the geometry of the mold and the properties of the material being used can lead to significant reductions in cycle times. By prioritizing efficient cooling design, manufacturers can achieve a balance between increased output and maintaining the quality of the final product.

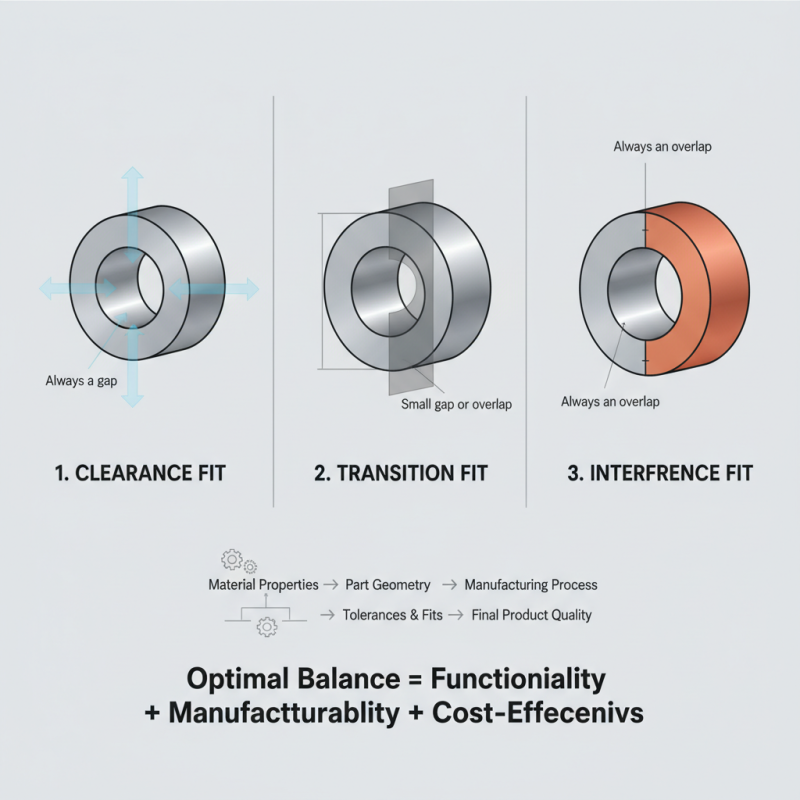

Understanding Tolerances and Fits in Mold Design

Understanding tolerances and fits in injection mold design is crucial for achieving optimal efficiency and quality in the manufacturing process. Tolerances refer to the allowable variations in the dimensions of molded parts, which can significantly impact the functionality and assembly of the final product. When designing molds, it’s essential to establish the appropriate tolerance levels based on the intended application and the characteristics of the materials being used. Tight tolerances may be necessary for precision components, but they can also increase production costs and cycle times, so finding the right balance is key.

In addition to tolerances, the concept of fits—how two mating components interact—is paramount to mold design. Fits are classified into categories such as clearance, interference, and transition, each serving different purposes in assembly and operation. A clearance fit ensures easy assembly and movement between parts, while an interference fit provides a snug connection, enhancing stability. Understanding the application requirements and selecting the right fits can prevent issues such as excessive wear, misalignment, or failure during operation. By carefully analyzing tolerances and fits, designers can create molds that not only meet specification but also enhance overall product performance and durability.

Mold Maintenance and Inspection for Long-term Performance

Mold maintenance and inspection are critical components in ensuring the longevity and efficiency of injection molds. According to industry reports, proper maintenance can extend the lifespan of molds by up to 30%, significantly reducing production costs and downtimes. Regular inspections allow for the early identification of wear and tear, which can prevent costly failures. Implementing a routine maintenance schedule that includes cleaning, lubrication, and functionality checks is paramount for achieving high performance and consistent quality in production.

One effective tip for mold maintenance is to utilize advanced monitoring technologies. Sensors can provide real-time data on various parameters, ensuring that any abnormal conditions are addressed promptly. Additionally, utilizing a planned preventive maintenance system can enhance mold reliability, which, as reported by the Society of Plastics Engineers, can lead to a 20% increase in overall equipment effectiveness.

Another important aspect is the documentation of all maintenance activities and inspection results. This practice not only aids in tracking mold performance over time but also helps in making informed decisions for future improvements. A study conducted by the American Society of Mechanical Engineers indicated that systematic documentation can improve maintenance response times by 40%, thereby promoting an efficient production environment. Overall, prioritizing mold maintenance and inspection not only enhances performance but also drives quality output, paving the way for a successful injection molding process.

Related Posts

-

Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023

-

2025 Guide: How to Calculate Injection Molding Mold Costs Effectively

-

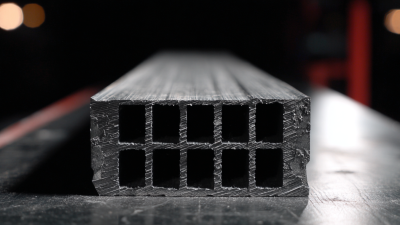

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

2025 Top 10 Innovations Revolutionizing the Injection Molding Process

-

10 Essential Tips for Working with Injection Moldable Plastics

-

Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting