Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

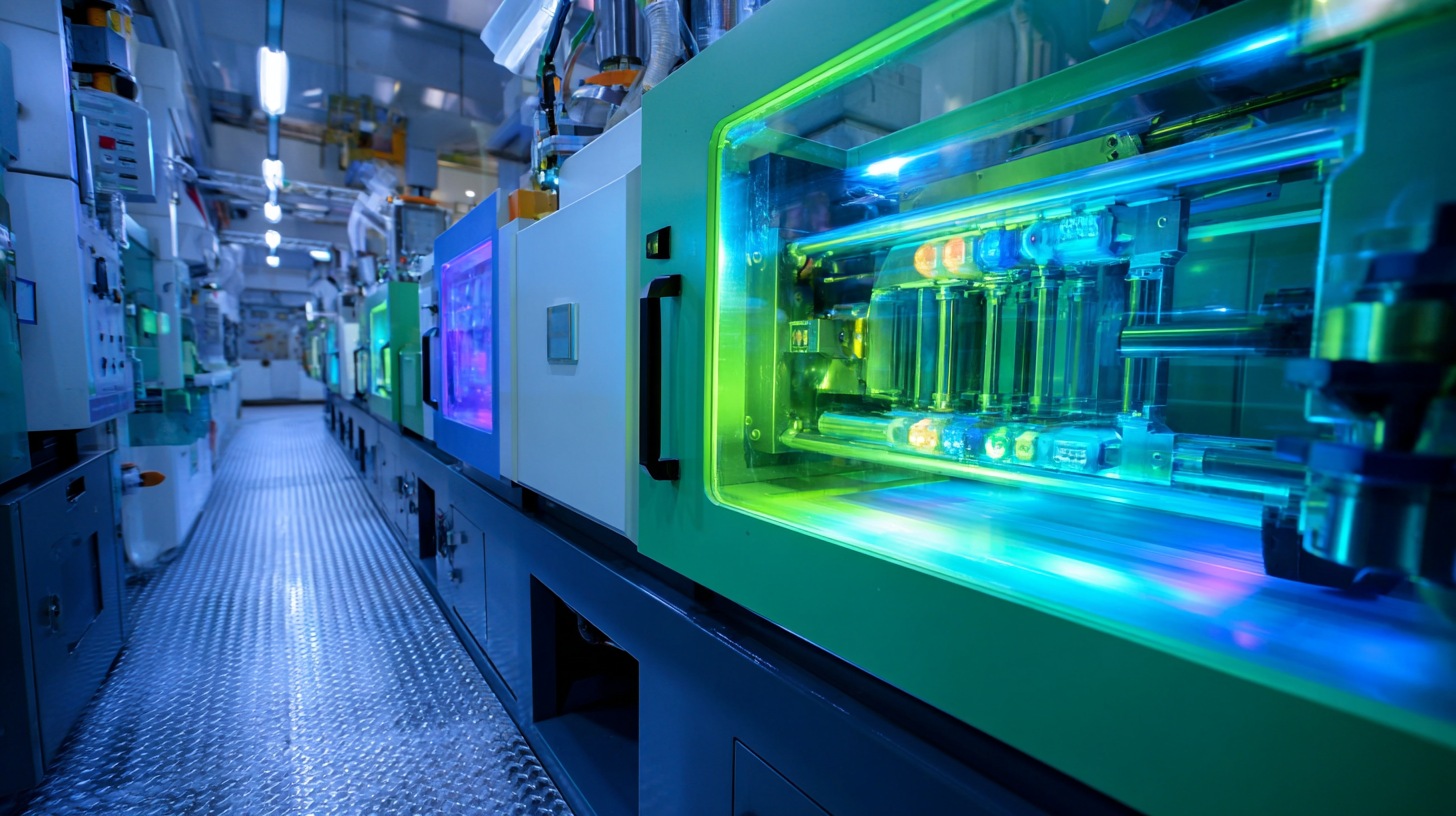

Injection molding is a cornerstone of Canada’s manufacturing sector, offering unparalleled efficiency and precision in producing complex components across various industries. According to a recent report by the Canadian Plastics Industry Association, the injection molding sector has seen a growth rate of approximately 3% annually, reflecting the rising demand for lightweight and durable materials in automotive, aerospace, and consumer goods. Notably, injection molding Canada not only supports local economies by creating jobs but also helps companies reduce waste and production costs, as it requires less material than traditional manufacturing methods. With advancements in technology driving innovation, the adoption of injection molding is expected to further enhance productivity and sustainability in Canadian manufacturing. As businesses pivot to embrace digital transformation, the role of injection molding will be pivotal in addressing both operational efficiency and market competitiveness in the evolving landscape.

Injection molding is a cornerstone of Canada’s manufacturing sector, offering unparalleled efficiency and precision in producing complex components across various industries. According to a recent report by the Canadian Plastics Industry Association, the injection molding sector has seen a growth rate of approximately 3% annually, reflecting the rising demand for lightweight and durable materials in automotive, aerospace, and consumer goods. Notably, injection molding Canada not only supports local economies by creating jobs but also helps companies reduce waste and production costs, as it requires less material than traditional manufacturing methods. With advancements in technology driving innovation, the adoption of injection molding is expected to further enhance productivity and sustainability in Canadian manufacturing. As businesses pivot to embrace digital transformation, the role of injection molding will be pivotal in addressing both operational efficiency and market competitiveness in the evolving landscape.

Key Benefits of Injection Molding for Canadian Manufacturers

Injection molding offers numerous advantages for Canadian manufacturers, positioning them competitively in the global market. One of the key benefits is its efficiency in mass production, allowing for the rapid creation of complex parts with high accuracy. This method reduces waste and cuts down on production time, which can significantly lower costs for manufacturers, particularly in a landscape where tariffs on imported molds are becoming increasingly burdensome.

Furthermore, the flexibility of injection molding means that manufacturers can easily adapt to changes in demand. With recent developments in the Canadian manufacturing sector, such as the expansion of local companies and the transition of services to new partners, it is essential for manufacturers to remain agile. Utilizing injection molding allows them to respond swiftly to market needs without compromising on quality.

**Tip:** To maximize the benefits of injection molding, consider investing in advanced machinery and technology that can further streamline the production process. Regular training for employees can also enhance efficiency, ensuring that your team is well-versed in the latest techniques and practices in the industry.

In addition, maintaining strong relationships with reliable suppliers can mitigate the impact of tariffs and supply chain disruptions. By fostering a collaborative environment, manufacturers can work together to innovate and stay ahead of market challenges.

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

Exploring Cost Efficiency in Injection Molding Processes

Injection molding has emerged as a cornerstone of cost efficiency in Canada’s manufacturing industry. This method allows for the mass production of high-quality parts at lower costs compared to traditional manufacturing processes. According to a report by the Canadian Plastics Industry Association, injection molding can reduce production costs by up to 30% when scaling up production volumes, making it an attractive option for manufacturers aiming to maximize their profit margins. The ability to create complex shapes in a single step also minimizes the need for secondary operations, leading to further cost savings.

Tips: To enhance cost efficiency in injection molding, manufacturers should invest in advanced machinery that offers higher precision and faster cycle times. Regular maintenance of these machines can prevent downtime and subsequent costs. Additionally, optimizing the design of parts for manufacturability can reduce material waste and enhance the effectiveness of the process.

Furthermore, the use of high-quality raw materials and innovative techniques, such as 3D printing molds, can significantly cut down on production times and costs. Industry research has shown that integrating sustainable practices within injection molding not only conserves resources but also appeals to eco-conscious consumers, potentially opening new markets and opportunities for cost-effective production.

Tips: Collaborating with suppliers who specialize in sustainable materials can lead to innovative solutions that benefit both the bottom line and the environment. Additionally, leveraging data analytics for process optimization can help identify areas for savings and efficiency improvements.

Enhancing Product Design Flexibility with Injection Molding

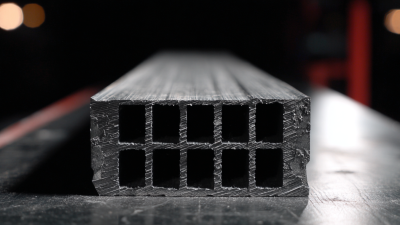

Injection molding stands out in Canada's manufacturing industry primarily due to its ability to enhance product design flexibility. This advanced process allows for the creation of intricate shapes and complex geometries that traditional manufacturing methods struggle to achieve. According to a report by CIMdata, over 40% of manufacturers have shifted towards injection molding in the past five years to capitalize on these advantages. Such flexibility not only improves aesthetics but also optimizes functionality, making it an ideal choice for industries ranging from automotive to consumer products.

Injection molding stands out in Canada's manufacturing industry primarily due to its ability to enhance product design flexibility. This advanced process allows for the creation of intricate shapes and complex geometries that traditional manufacturing methods struggle to achieve. According to a report by CIMdata, over 40% of manufacturers have shifted towards injection molding in the past five years to capitalize on these advantages. Such flexibility not only improves aesthetics but also optimizes functionality, making it an ideal choice for industries ranging from automotive to consumer products.

Moreover, the speed and efficiency of injection molding facilitate rapid prototyping and iterative design processes. The ability to quickly produce prototypes allows Canadian manufacturers to respond swiftly to market trends and consumer demands. A study from the Canadian Plastics Industry Association indicates that companies utilizing injection molding can reduce product development timelines by up to 30%. This agility is crucial in a competitive landscape where innovation can make or break a product's success. With ongoing advancements in materials and technology, injection molding continues to redefine the possibilities of product design in Canada’s manufacturing sector.

Reducing Waste and Promoting Sustainability in Manufacturing

Injection molding has emerged as a pivotal process in Canada's manufacturing industry, significantly contributing to waste reduction and sustainability. As industries increasingly adopt environmentally friendly practices, the efficiency of injection molding becomes more pronounced. According to a report by the Canadian Plastics Industry Association, injection molding generates up to 50% less waste compared to traditional manufacturing methods, owing to its ability to produce complex shapes with minimal excess material. This not only streamlines production but also lessens the environmental footprint, positioning injection molding as a key player in promoting sustainability.

Furthermore, the process's ability to use recycled materials is revolutionizing the way manufacturers approach production. A study by the Canadian Government's Sustainable Development Strategies highlights that utilizing recycled plastics in injection molding can lessen energy consumption by up to 30%. This aligns with the broader industry trend towards circular economy principles, where waste products are reincorporated into the production cycle, thus fostering a more sustainable manufacturing environment. By reducing material waste and lowering energy requirements, injection molding stands out as a crucial technology for manufacturers looking to enhance their sustainability initiatives.

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry - Reducing Waste and Promoting Sustainability in Manufacturing

| Advantage | Description | Impact on Sustainability | Waste Reduction (%) |

|---|---|---|---|

| Material Efficiency | Minimizes excess material usage through precision. | Significantly reduces scrap and waste. | 30% |

| Energy Efficiency | Lower energy consumption compared to other methods. | Reduces carbon footprint in production. | 20% |

| Recyclability of Materials | Use of recyclable materials increases lifecycle. | Promotes circular economy practices. | 25% |

| Automation Potential | High degree of automation reduces labor waste. | Increases efficiency and reduces human error. | 15% |

| Design Flexibility | Allows for complex geometries that minimize waste. | Enhances product functionality while reducing material use. | 18% |

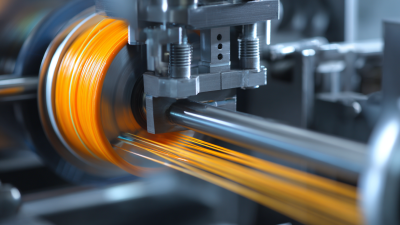

Evaluating the Speed of Production with Injection Molding Techniques

Injection molding is a groundbreaking technique that significantly enhances the speed of production in Canada's manufacturing industry. This process involves injecting molten material into a mold, allowing manufacturers to produce intricate shapes and high volumes of parts more quickly than traditional manufacturing methods. The efficiency gained from this method not only reduces lead times but also increases throughput, enabling companies to meet market demands swiftly and effectively.

Moreover, the precision of injection molding contributes to faster production cycles. With advanced technology, manufacturers can develop molds that ensure consistent quality and accuracy in each molded part. This precision minimizes the need for post-production adjustments and rework, further streamlining the overall manufacturing process. As a result, businesses can quickly capitalize on new opportunities and respond to consumer trends, solidifying their competitive edge in a dynamic market.

Related Posts

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development