Why Is Injection Molding the Best Choice for Prototyping and Production

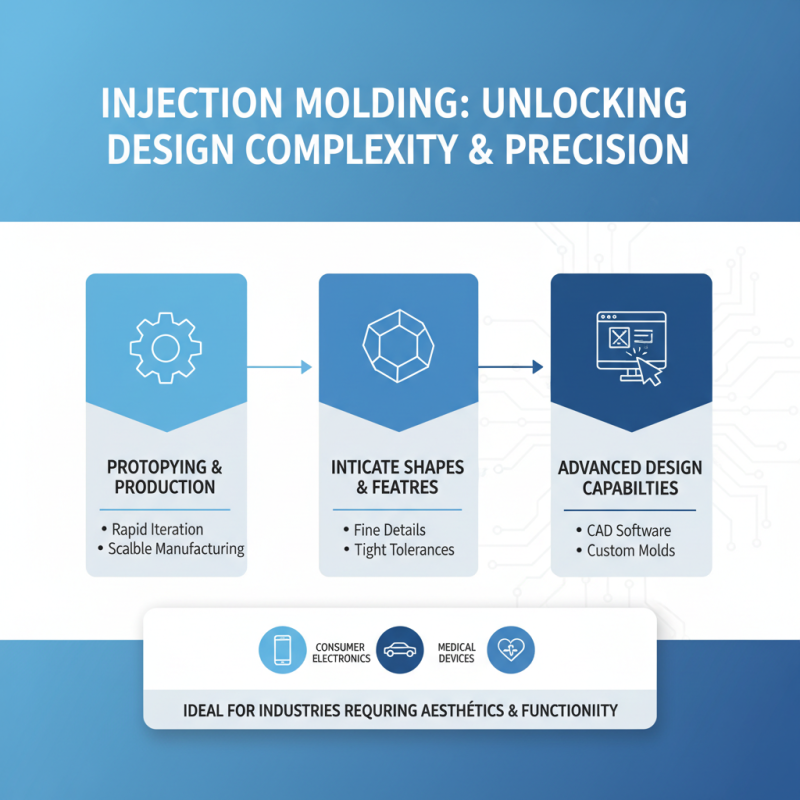

Injection molding has emerged as a leading choice in both prototyping and production for a variety of industries. This manufacturing process involves injecting molten material into a mold to create finely detailed parts, making it particularly advantageous for producing high-quality prototypes that closely resemble the final product. Its efficiency allows for rapid iteration during the design phase, enabling engineers and designers to test concepts and make adjustments with minimal lead time. The precision of injection molding not only accelerates the prototyping process but also ensures that the geometries and tolerances of the components meet stringent quality standards.

Beyond prototyping, injection molding stands out in mass production due to its ability to create complex shapes with consistent repeatability. The scalability of this process allows manufacturers to produce large volumes of parts quickly and cost-effectively. As a result, businesses can meet high demand without sacrificing quality, making injection molding an ideal solution for companies looking to optimize their production lines. This combination of speed, precision, and scalability positions injection molding as the best choice for both prototyping and production, offering a pathway to innovation and efficiency in a competitive marketplace.

Benefits of Injection Molding for Prototyping and Production

Injection molding is a highly efficient manufacturing process that offers numerous benefits for both prototyping and production. One of the primary advantages of injection molding is its ability to produce high-quality parts with excellent dimensional accuracy and surface finish. This is particularly crucial in prototyping, where the goal is to validate designs and test functionality before committing to mass production. The consistency achieved through injection molding reduces the likelihood of defects, leading to more reliable prototypes and a smoother transition into full-scale manufacturing.

When considering injection molding for your projects, it's important to keep in mind several key tips to maximize its benefits. First, invest time in designing your mold carefully, as a well-designed mold can significantly reduce production costs and lead times. Additionally, consider the material being used; different plastics can enhance the properties of your final product, such as durability and heat resistance, depending on its intended application. Lastly, engage with experienced manufacturers early in the process to leverage their expertise in optimizing designs for injection molding, ensuring that both prototyping and production stages are executed seamlessly.

Overall, injection molding stands out as an optimal choice for organizations seeking to streamline their prototyping and production processes, thanks to its unparalleled efficiency and quality output.

Benefits of Injection Molding for Prototyping and Production

Cost Efficiency in Injection Molding Manufacturing Processes

Injection molding stands out in manufacturing due to its impressive cost efficiency, especially when it comes to prototyping and high-volume production. According to a report by the American Society of Mechanical Engineers, the initial tooling cost for injection molding may seem high, averaging around $5,000 to $100,000 depending on the complexity of the mold. However, this investment quickly pays off in reduced per-unit costs as production scales. For example, in high-volume runs exceeding 10,000 units, the cost per part can drop dramatically to as low as $0.10, a fraction of the cost in other manufacturing processes such as 3D printing or CNC machining.

Furthermore, injections molding allows for rapid production cycles, with a single mold capable of producing thousands of parts per hour. This efficiency is particularly beneficial when time-to-market is critical in industries like automotive and consumer products. Research published by the Society of Plastics Engineers highlights that a typical injection molding cycle can take as little as 15-30 seconds, depending on part size and complexity. Thus, the combination of low unit costs and high production speeds positions injection molding as a smart choice for manufacturers looking to balance quality and budget in their prototyping and production processes.

Why Is Injection Molding the Best Choice for Prototyping and Production - Cost Efficiency in Injection Molding Manufacturing Processes

| Aspect | Details |

|---|---|

| Initial Setup Cost | Higher due to mold creation |

| Production Volume | Ideal for high-volume production |

| Material Versatility | Compatible with various thermoplastics and thermosets |

| Production Speed | Rapid cycle times, improving cost efficiency |

| Part Complexity | Can produce complex geometries with precision |

| Waste Reduction | Minimized material waste compared to other methods |

| Quality Consistency | High repeatability ensures uniform quality across batches |

Speed and Scalability of Injection Molding for Large Production Runs

Injection molding is renowned for its speed and scalability, making it an ideal choice for both prototyping and large production runs. The process allows manufacturers to produce high volumes of parts quickly and efficiently, meeting the demands of various industries. With the ability to create complex designs with precision, injection molding can significantly reduce the time from concept to market, allowing businesses to capitalize on opportunities swiftly.

One of the key advantages of injection molding is its ability to produce consistent quality across large batches. This is particularly important when scaling up production, as maintaining uniformity ensures that each part meets the required specifications. Additionally, once a mold is created, the cost per unit decreases with larger quantities, making it an economically viable option for mass production.

Tips: When considering injection molding for your projects, ensure that your designs are optimized for the process. This includes minimizing the number of parts and ensuring proper mold flow to enhance efficiency. Collaborating closely with your manufacturing partners during the design phase can also lead to better outcomes and reduced production times. By focusing on these aspects, you can fully leverage the benefits of injection molding in your prototyping and production efforts.

Complexity and Precision in Injection Molding Designs

Injection molding stands out as an exceptional method for prototyping and production, particularly due to its capability to manage complexity and precision in design. The process allows for the creation of intricate shapes and detailed features that are often unattainable through other manufacturing techniques. This level of complexity is crucial for industries where product aesthetics and functionality coexist, such as consumer electronics, automotive, and medical devices. By utilizing advanced computer-aided design (CAD) software, designers can create molds that incorporate fine details, ensuring that the end product meets the stringent specifications of the market.

Moreover, the precision of injection molding ensures a high degree of consistency in each produced part. Each mold allows for the replication of the original design with minimal variation, which is essential for maintaining quality control during production runs. This precision not only reduces waste resulting from defective components but also streamlines the assembly process, as parts fit together with greater accuracy. The result is a more efficient production cycle that can quickly adapt to changes in design, making injection molding a superior choice for both prototyping and full-scale manufacturing. In an era where innovation is key, the ability to produce complex and precise designs efficiently gives companies a significant competitive edge.

Material Versatility and Options in Injection Molding Techniques

Injection molding is widely recognized for its excellent material versatility, making it a preferred choice for both prototyping and mass production. Various thermoplastics, such as ABS, polypropylene, and nylon, can be easily molded into intricate shapes, allowing designers to experiment with different materials to achieve desired mechanical properties, aesthetics, and functional requirements. According to a recent industry report by Grand View Research, the global injection molding market is projected to reach $300 billion by 2025, showcasing the strong demand for diverse materials and innovative solutions within the manufacturing sector.

Different injection molding techniques offer varying benefits in terms of material options. For instance, multi-material injection molding allows the combination of different polymers in a single product, providing enhanced functionality and performance attributes, such as improved durability or aesthetic appeal. Additionally, advancements in technology have led to the use of biodegradable plastics, enabling manufacturers to meet sustainability goals while maintaining the benefits of injection molding.

**Tips:** When selecting materials for injection molding, consider the mechanical and thermal properties required for your application. It’s also beneficial to explore the potential of using recycled materials, which can not only reduce costs but also promote environmental sustainability in your production processes. Lastly, consult with industry specialists to tailor your material choice to specific project goals, ensuring that the end product meets the highest standards of quality and performance.

Related Posts

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

-

Top 5 Benefits of Using Plastic Molding in Modern Manufacturing Processes

-

Why Plastic Injection Molding is Essential for Modern Manufacturing Success

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025