Why Injection Molding is Essential for Modern Manufacturing Success

Injection molding stands as a cornerstone of modern manufacturing, enabling the efficient production of complex parts with high precision and consistency. As noted by industry expert Dr. Emily Carter, “The versatility and scalability of injection molding make it indispensable for businesses looking to innovate and meet market demands.” This underscores the critical role that injection molding plays in various sectors, from automotive to consumer goods, as companies strive to remain competitive in a rapidly evolving landscape.

The process not only allows for the mass production of intricate designs but also minimizes waste and reduces costs, which is vital for sustainable manufacturing practices. By leveraging advanced technologies and materials, injection molding continues to push the boundaries of what is possible in product design and functionality. As manufacturers embrace this powerful technique, they unlock new opportunities for efficiency and growth, ultimately shaping the future of the industry.

Therefore, understanding the significance of injection molding in modern manufacturing is essential for businesses aiming to achieve success and stay ahead of their competitors. With continuous advancements and applications, the relevance of injection molding will only grow, solidifying its place as an essential element in the manufacturing landscape.

The Role of Injection Molding in Product Development and Design

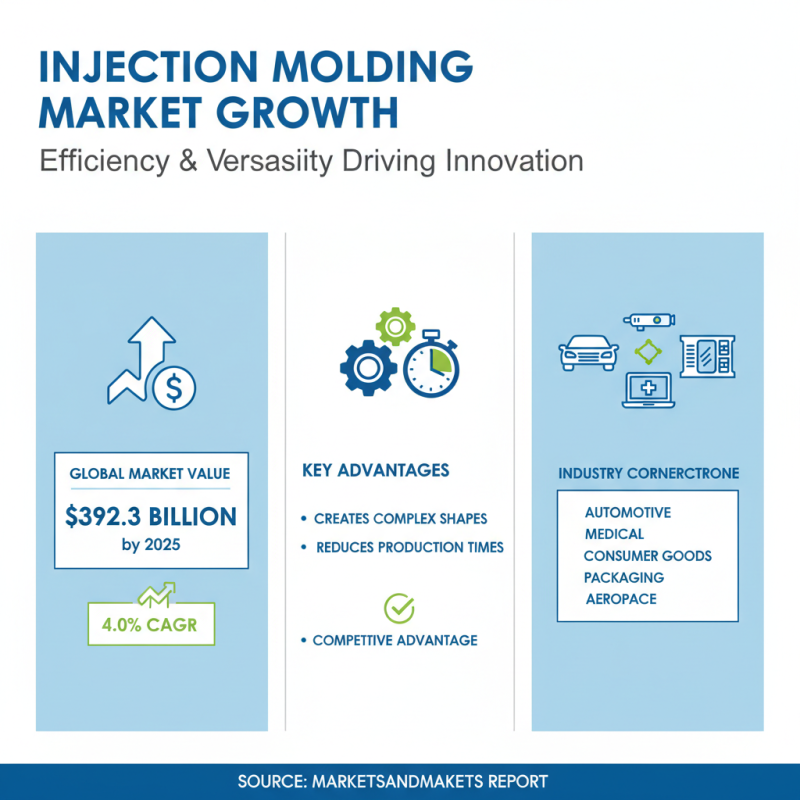

Injection molding has become a cornerstone in product development and design across various industries due to its efficiency and versatility. According to a report from MarketsandMarkets, the global injection molding market is expected to reach $392.3 billion by 2025, with an annual growth rate of approximately 4.0%. This growth reflects the significance of injection molding in creating complex shapes and reducing production times, which are crucial for maintaining competitive advantages in the fast-paced manufacturing landscape.

The role of injection molding in product design goes beyond mere production; it significantly influences material selection, dimensional accuracy, and the overall design process. With capabilities to produce high volumes of parts consistently, manufacturers can rapidly prototype and iterate designs, ultimately speeding up time-to-market. A survey conducted by the Society of Plastics Engineers revealed that 68% of companies consider injection molding their primary method for translating design ideas into tangible products. This method not only enhances design flexibility but also allows for innovations such as the integration of multi-materials and complex geometries, thereby maximizing product functionality and performance.

Key Advantages of Injection Molding for Cost-Effective Manufacturing

Injection molding stands out as a pivotal technique in modern manufacturing, primarily due to its cost-effectiveness and efficiency. According to a report by Grand View Research, the global injection molding market was valued at approximately $238 billion in 2021, with expectations to expand at a compound annual growth rate (CAGR) of 5.4% from 2022 to 2030. This growth underscores the increasing reliance on injection molding for producing high-quality components at lower costs.

One of the key advantages of injection molding is its capacity for mass production. The process enables manufacturers to create hundreds to thousands of identical parts with minimal variation. This efficiency not only reduces the labor costs associated with production but also lowers per-unit costs significantly. A study from the Society of Plastics Engineers highlights that injection molding offers a cost savings of up to 50% compared to traditional manufacturing methods when producing large quantities. Furthermore, the ability to use various materials, from thermoplastics to elastomers, makes injection molding adaptable for multiple industries, enhancing its appeal in a rapidly evolving marketplace.

Additionally, injection molding minimizes waste, making it an environmentally friendly choice in comparison to other manufacturing processes. The closed-loop system of injection molding ensures that excess material can be recycled and reused, contributing to sustainability goals that are increasingly prioritized by manufacturers. As sustainability initiatives gain traction, the cost reduction and efficiency of injection molding will likely continue to position it as a cornerstone of modern manufacturing strategies.

Material Versatility: Selecting the Right Plastics for Injection Molding

Material selection is a critical aspect of injection molding that directly impacts the quality, performance, and cost-effectiveness of manufactured products. The versatility of materials available for injection molding is vast, enabling manufacturers to choose plastics that best match their specific application requirements. From thermoplastics like ABS and polycarbonate to thermosetting plastics such as epoxy resins, each material offers unique properties that cater to different functional needs, including durability, flexibility, heat resistance, and weight.

Furthermore, the right selection of materials can significantly influence the end product's functionality and longevity. For instance, selecting a high-impact plastic can enhance the product's resilience in demanding environments, while lighter materials may be preferred in applications that prioritize weight reduction. As manufacturers aim for sustainability, bioplastics and recycled materials are increasingly becoming viable alternatives, allowing companies to meet environmental standards without compromising on performance. This emphasis on material versatility not only strengthens the production process but also enhances a manufacturer’s ability to innovate and adapt in an ever-evolving industry landscape.

Sustainability Practices in Injection Molding for Modern Industry

Sustainability practices in injection molding are becoming increasingly vital as industries strive to reduce their environmental footprint while maintaining efficiency and quality. The injection molding process itself is known for producing minimal waste compared to traditional manufacturing methods. According to a report by the American Society of Plastic Engineers, advancements in injection molding technology have led to a reduction in energy consumption by up to 30% over the past decade, showcasing significant progress toward sustainable operations.

Moreover, many companies are now incorporating recycled materials into their injection molding processes. The recent Global Plastics Sustainability Report indicates that the use of recycled plastics in injection molding has increased by 15% in the last five years, reflecting a broader industry shift towards more sustainable practices. By utilizing post-consumer recycled materials, manufacturers not only contribute to waste reduction but also enhance their brand reputation among environmentally conscious consumers. This trend is indicative of a growing need for sustainability in modern manufacturing, aligning business success with ecological responsibility.

Future Trends in Injection Molding Technology and Its Impact on Manufacturing

The future of injection molding technology is poised for significant advancements that will greatly influence modern manufacturing. Key trends include the integration of smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), which enhance efficiency and precision in production. According to a report by Grand View Research, the global injection molding market is expected to reach USD 347.35 billion by 2027, driven by the increasing demand for lightweight and durable materials across various industries.

Another significant development is the rise of sustainable materials and processes. With growing environmental concerns, manufacturers are shifting toward bio-based and recycled plastics, which can reduce waste and carbon footprints. The adoption of these sustainable practices is projected to increase in the coming years, as companies prioritize eco-friendly manufacturing solutions. A study by Research and Markets forecasts that the sustainable plastic market will grow at a CAGR of 9.7% from 2021 to 2028.

Tips: Embracing new technologies is crucial for staying competitive. Consider investing in advanced mold design software to streamline your production process. Additionally, exploring partnerships with suppliers focused on sustainable materials can enhance your brand’s environmental credentials and appeal to eco-conscious consumers. Engage in continuous learning and training for your workforce to adapt to the evolving technological landscape and optimize production capabilities.

Injection Molding Technology Trends (2023)

Related Posts

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

2025 Top 10 Innovations Revolutionizing the Injection Molding Process