2026 How to Optimize Injection Molding Processes in USA Manufacturing?

In the competitive landscape of manufacturing, optimizing injection molding processes is crucial for success in the USA. Injection molding USA plays a significant role in producing high-quality plastic parts. However, many companies struggle with efficiency and waste management. Understanding the factors that influence the molding process can lead to better outcomes.

Identifying key variables, such as temperature and pressure, is essential. These elements directly impact the final product's quality. Yet, companies often overlook them and face quality inconsistencies. It’s vital to monitor these aspects continuously to avoid errors. Additionally, material selection can make a significant difference in the efficiency of injection molding. Choosing the right plastic can enhance performance but requires careful consideration.

Embracing advanced technologies can provide a competitive edge. Automation and data analytics are becoming popular. However, some manufacturers hesitate due to cost. While innovation might seem daunting, it's necessary to adapt or risk falling behind. Reflecting on these challenges can inspire a more efficient, sustainable approach in the injection molding sector.

Understanding Injection Molding: Basics and Key Terminology

Injection molding is a widely used manufacturing process. It's essential to understand its basics to optimize efficiency. The process involves creating parts by injecting molten material into a mold. This can include plastics or metals. Key terminology includes "mold," "injection unit," and "clamping force." Each term plays a critical role in the overall process.

Molds are intricate and often complex. They determine the final part's shape and surface finish. The injection unit is where materials are melted and injected. Proper temperature control is vital here. Clamping force holds the mold shut during injection. Insufficient force can lead to defects, which is a common issue in the industry.

It's also important to address challenges in injection molding. Many operators struggle with cycle times and material waste. Balancing speed and quality is difficult. Adjustments are often needed. Some may overlook routine maintenance of machinery. This oversight can lead to diminished performance. Regular checks are essential to maintain effectiveness and efficiency. Recognizing these issues lays the groundwork for better practices in the future.

Optimization of Injection Molding Processes in USA Manufacturing (2026)

This chart represents the key performance metrics for optimizing injection molding processes in 2026. The metrics include Cycle Time, Material Costs, Energy Consumption, Scrap Rate, and Production Rate, each critical for improving efficiency in USA manufacturing.

Identifying Critical Factors Affecting Injection Molding Efficiency

Optimizing injection molding processes is crucial for improving efficiency in manufacturing. Various factors significantly influence this area. A recent industry report highlighted that cycle time, material selection, and machine conditions are key elements to monitor. About 40% of inefficiencies arise from poor machine setup and maintenance. Regular maintenance schedules can help reduce downtime.

Material selection plays a vital role as well. Using the right resin can increase the flow rate and, in turn, improve cycle times. Reports indicate that using optimized materials can increase production speeds by up to 20%. However, many manufacturers still rely on outdated materials, which can prevent operations from reaching their full potential.

Additionally, temperature control is often overlooked. Inadequate heating or cooling can lead to defects and increased waste. Studies show that maintaining optimal temperature balance during injection can reduce scrap rates by 15%. This is an area where continuous improvement is necessary. Many manufacturers may not track these variables closely enough, leading to missed opportunities for enhanced efficiency.

2026 How to Optimize Injection Molding Processes in USA Manufacturing? - Identifying Critical Factors Affecting Injection Molding Efficiency

| Critical Factor | Description | Impact on Efficiency | Optimization Strategies |

|---|---|---|---|

| Mold Design | Effective mold design reduces cycle times. | High | Utilize simulation software to optimize flow. |

| Material Selection | Choosing the right materials ensures better quality. | Medium | Evaluate material properties and performance. |

| Temperature Control | Proper temperature management is vital for consistent quality. | High | Implement advanced heating and cooling systems. |

| Cycle Time Management | Optimizing cycle time increases production rates. | High | Analyze and reduce non-productive time. |

| Machine Maintenance | Regular maintenance prevents downtime. | Medium | Schedule regular inspections and proactive upgrades. |

Techniques for Optimizing Material Selection and Process Parameters

Optimizing material selection and process parameters is crucial for efficient injection molding in the USA manufacturing sector. According to a recent industry report, optimizing these factors can reduce production costs by 15-25%. Materials play a vital role in determining the outcome. Choosing the right resin can affect cycle time, quality, and even durability of the final product.

Tips for material selection: evaluate the necessary properties for the desired application. Consider mechanical strength, temperature resistance, and clarity. It’s essential to balance cost and performance. Remember, cheaper materials may lead to compromised quality. This trade-off can lead to increased waste and higher costs over the lifespan of the product.

Analyzing process parameters is equally important. Small changes in temperature or pressure can lead to significant differences in outcomes. A recent study found that adjusting mold temperature by just 5°C can improve part quality by 20%. Such modifications can reduce defects. Always monitor and adjust parameters based on real-time data for optimal results. Being reactive is key in this fast-paced industry. Reflecting on past errors can provide valuable insights for future adjustments.

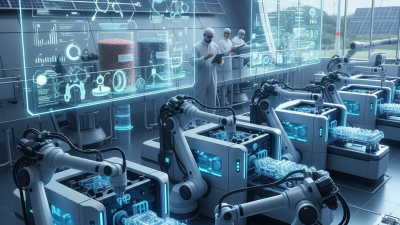

Implementing Advanced Technology in Injection Molding Operations

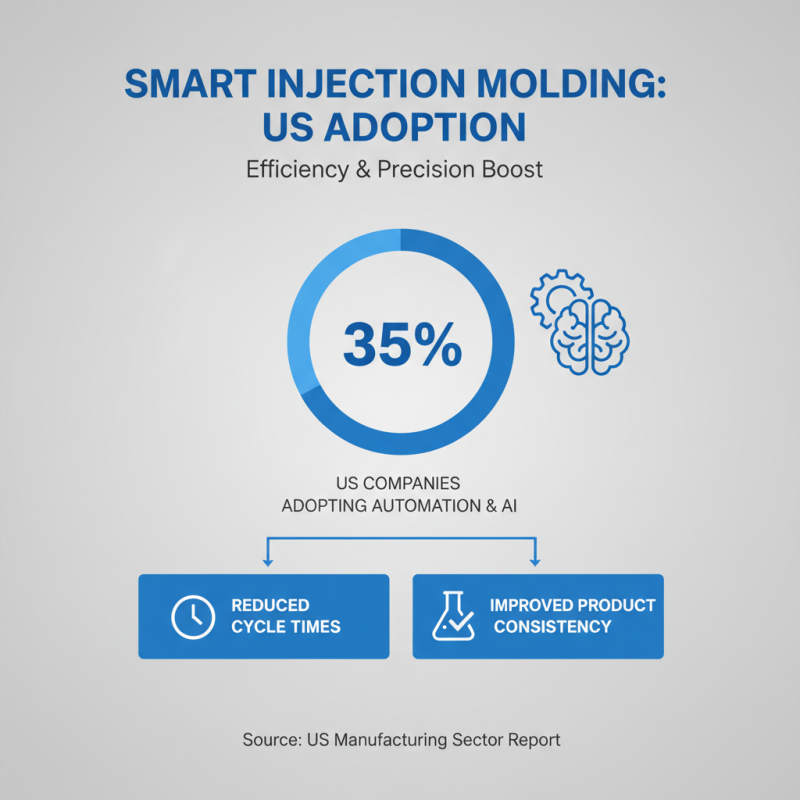

Implementing advanced technology in injection molding operations can greatly enhance efficiency and precision. In the U.S. manufacturing sector, approximately 35% of companies are now adopting automation and AI tools in their injection molding processes. These technologies help in reducing cycle times and improving product consistency.

One key approach is adopting data analytics. By using real-time data, manufacturers can monitor machine performance and predict maintenance needs. A report from the American Society for Quality indicated that predictive maintenance can cut downtime by 20%. This optimization leads to significant cost savings and boosts productivity.

**Tip:** Regularly train your team on new technologies. A well-informed workforce is crucial for successful implementation.

Advanced simulation software can also streamline design processes. This allows for virtual testing and adjustments before production begins. It minimizes waste and errors, enhancing overall quality. A study found that using simulation can reduce prototype costs by 30%. However, integrating such technologies requires time and investment, which not all manufacturers are ready to commit to.

**Tip:** Start with small-scale trials. Evaluate results before committing to larger investments. This approach helps mitigate risk and allows for adjustments based on initial findings.

Measuring and Analyzing Performance to Drive Continuous Improvement

In injection molding, measuring performance is crucial for improvement. Key metrics include cycle time, scrap rate, and productivity. These numbers provide insights into where adjustments are needed. Regular data collection allows manufacturers to spot patterns over time. This helps in identifying bottlenecks and inefficiencies. Yet, relying solely on data can create blind spots.

Analyzing performance is about more than just numbers. It requires critical thinking and troubleshooting. Sometimes, the problem lies not in the process but in operator training. This aspect is often overlooked. Investing in skilled personnel can lead to significant improvements. However, companies frequently underestimate this need and focus on machinery upgrades instead.

Continuous improvement demands an open mindset. It’s important to welcome feedback, even if it’s uncomfortable. Teams should feel free to express concerns about the process. A culture of open communication fosters innovation. Challenges can lead to unexpected solutions. Emphasizing analysis alongside a willingness to adapt can drive true performance enhancement in injection molding.

Related Posts

-

2025 Top 10 Innovations Revolutionizing the Injection Molding Process

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Top 10 Factors Affecting Injection Molding Estimate Costs You Should Know

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

The Future of Injection Tooling in Sustainable Manufacturing Practices