Why Plastic Extrusion is the Key to a $300 Billion Manufacturing Sector Growth?

The plastic extrusion industry is poised to play a pivotal role in driving the growth of the $300 billion manufacturing sector. As companies increasingly seek efficient and cost-effective production methodologies, plastic extrusion emerges as an essential process, enabling the mass production of a wide range of products across diverse applications. According to a recent industry report from Market Research Future, the global plastic extrusion market is projected to grow at a CAGR of 5.6% from 2021 to 2028, underscoring its vital importance and relevance to manufacturing dynamics.

Industry expert Dr. Sarah Thompson, a leading authority in materials science and innovation, emphasizes the significance of plastic extrusion in modern manufacturing. She states, "The scalability and versatility of plastic extrusion not only enhance production capabilities but also drive sustainability in product design, making it an indispensable tool for manufacturers today." With advancements in technology and an increasing shift towards sustainable practices, the plastic extrusion process is set to redefine production efficiencies, contributing significantly to both economic growth and environmental stewardship. As manufacturers continue to leverage this technology, the potential for innovation and market expansion remains boundless, signaling a transformative era for the manufacturing landscape.

The Essential Role of Plastic Extrusion in Modern Manufacturing

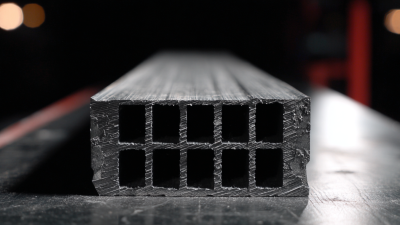

Plastic extrusion plays a crucial role in the modern manufacturing landscape, serving as a foundational process for a multitude of industries. By transforming plastic materials into specific shapes and profiles, it enables the production of various products ranging from packaging films to structural components. The efficiency and versatility of plastic extrusion make it indispensable in sectors such as construction, automotive, and consumer goods, where demand for custom solutions and high-volume output is ever-increasing.

Moreover, the evolution of plastic extrusion technology has led to significant advancements in sustainability and material innovation. Manufacturers are now able to utilize recycled plastics, thereby reducing waste and minimizing environmental impact. Techniques such as co-extrusion enable the combination of multiple materials in one streamlined process, allowing for enhanced product performance while also catering to eco-friendly initiatives. As industries strive to meet both consumer demand and regulatory pressures, plastic extrusion stands out as a key driver of growth and innovation in the $300 billion manufacturing sector.

Growth Drivers in the $300 Billion Plastic Manufacturing Sector

The $300 billion plastic manufacturing sector is experiencing unprecedented growth, driven by several key factors. The increasing demand for lightweight and durable materials in automotive, packaging, and construction industries is a primary growth catalyst. According to a report by MarketsandMarkets, the global plastic extrusion market alone is projected to grow at a compound annual growth rate (CAGR) of 5.3%, reaching $268 billion by 2025. This momentum is fueled by advancements in extrusion technology that enhance efficiency and reduce waste, making plastic products more economically viable.

Another significant driver is the rising trend of sustainability in manufacturing. Many companies are adopting recycled plastics and bioplastics to meet consumer preferences and regulatory requirements for eco-friendly products. A study by Grand View Research indicates that the global bioplastics market is expected to exceed $25 billion by 2028, further reflecting the sector's shift toward sustainable practices. This transition not only aligns with global environmental goals but also opens up new market opportunities, reinforcing the critical role of plastic extrusion in driving the sector's growth within this dynamic landscape.

Innovative Applications of Extruded Plastics Across Various Industries

The use of extruded plastics is rapidly transforming various industries, paving the way for innovative applications that drive manufacturing growth. The global market for extruded flat plastic mesh beds, which was valued at $2.24 billion in 2024, is projected to reach $3.38 billion by 2033, highlighting the demand for tailored and efficient production processes. This surge reflects a broader trend where manufacturers are increasingly adopting extrusion technology to produce specialized materials, such as lightweight and durable polypropylene foams, that meet the ever-evolving needs of consumers.

Moreover, events like the CHINAPLAS 2026 showcase the pivotal role of extrusion in the plastic industry. As leading companies unveil advancements in plastic machinery and sustainable materials, the emphasis on high-quality and eco-friendly production methods becomes more pronounced. Applications of extruded plastics extend beyond traditional sectors, permeating areas such as automotive, consumer products, and even sports equipment, reinforcing their significance in a $300 billion manufacturing sector aimed at innovation and growth.

Sustainability Challenges and Solutions in Plastic Extrusion

Plastic extrusion has emerged as a pivotal process in the manufacturing sector, particularly with the increasing focus on sustainability challenges. The plastic extrusion market is projected to reach approximately $300 billion by 2025, as reported by Grand View Research. However, the industry faces significant hurdles regarding environmental impact, with the production and disposal of plastic contributing greatly to pollution. A vital aspect of addressing these sustainability challenges lies in adopting more eco-friendly practices, such as utilizing biodegradable materials and improving recycling processes within extrusion operations.

To combat the environmental footprint, manufacturers can implement advanced technologies, such as industrial 3D printing, which reduces waste and optimizes material use. Furthermore, leveraging recycled plastics, which have seen a surge in usage, can not only reduce reliance on virgin materials but also enhance the sustainability of the extrusion process. According to a study by the Plastic Pollution Coalition, increasing the use of recycled plastic could minimize plastic waste by over 50%, transforming the industry while meeting growing consumer demand for sustainable products.

**Tip**: Consider integrating a closed-loop system in your manufacturing process to recycle waste material back into production, enhancing sustainability while also cutting costs.

**Tip**: Stay informed about the latest innovations in bioplastics and sustainable materials to keep your business ahead in the competitive extrusion market.

Future Trends Shaping Plastic Extrusion Technology by 2025

The trends shaping plastic extrusion technology in the coming years are critical for the growth of the industry, particularly as markets expand significantly. The global plastic extruded grid mattress market is projected to soar from $2.24 billion in 2024 to an impressive $3.38 billion by 2033, highlighting the rising demand for innovative materials in consumer products. This growth reflects not only consumer preferences but also the increasing focus on sustainable and efficient manufacturing processes.

Additionally, the low-density polyethylene (LDPE) market is expected to see notable expansion. From a valuation of $37.62 billion in 2025, it is anticipated to reach $46.16 billion by 2034, with a modest annual growth rate of 2.3%. This trajectory emphasizes the importance of advancements in plastic extrusion technology, which is continuously evolving to meet industry standards and environmental regulations. Emerging technologies and strategic innovations are paving the way for a more sustainable and resilient manufacturing sector, underlining plastic extrusion's pivotal role in future industrial developments.

Related Posts

-

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting