Why Plastic Injection Molding is Essential for Modern Manufacturing Success

In the ever-evolving landscape of modern manufacturing, plastic injection molding has emerged as a pivotal process that drives efficiency, precision, and innovation. As manufacturing challenges grow increasingly complex, industry experts emphasize the significance of adopting advanced techniques. John Smith, a renowned authority in the plastic injection molding sector, states, “The ability to create high-quality, intricate parts at scale is what sets successful manufacturers apart.” This quote encapsulates the essence of why plastic injection molding is not just a method but a cornerstone of competitive advantage in various industries.

The process of plastic injection molding allows for the rapid production of components with remarkable accuracy, facilitating a quick turnaround that is essential in today’s fast-paced market. As manufacturers strive to meet the demands of consumers who are always expecting more in terms of quality and sustainability, the strategic implementation of plastic injection molding becomes crucial. By understanding its benefits—such as reduced waste, lower labor costs, and the capability for complex designs—companies can harness this technology to streamline operations and enhance product offerings. Thus, embracing plastic injection molding is not merely an option; it is an essential strategy that underpins modern manufacturing success.

The Fundamentals of Plastic Injection Molding in Manufacturing

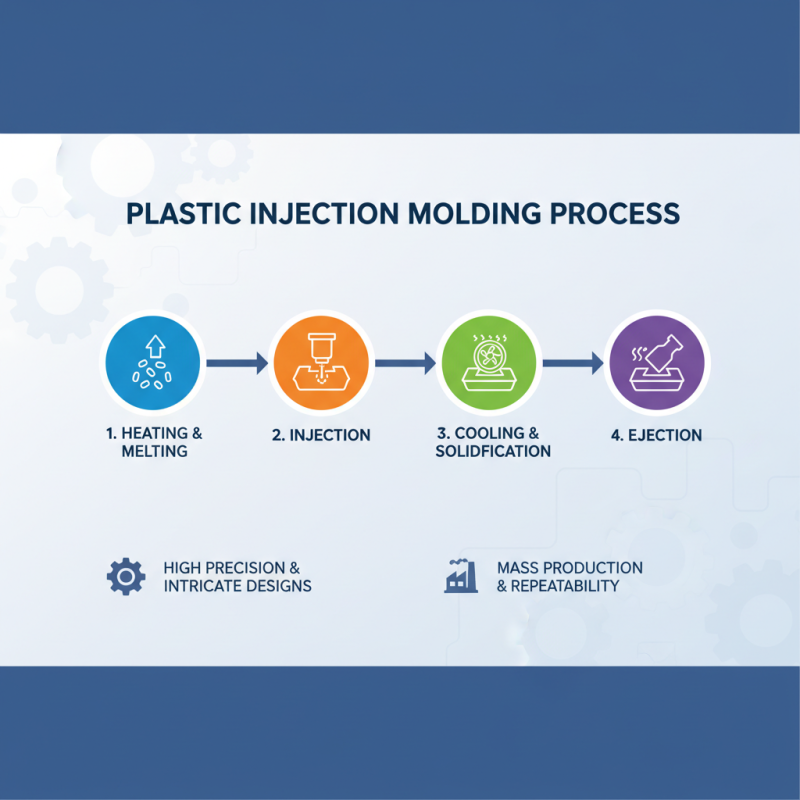

Plastic injection molding is a crucial process in modern manufacturing, serving as a backbone for the production of a wide range of plastic components used in various industries. The fundamentals of this technique involve the heating of plastic pellets until they melt and become malleable. This molten plastic is then injected into a mold under high pressure, allowing it to take the shape of the desired product. Once cooled, the mold is opened, and the solidified piece is ejected. This method not only enables intricate designs but also ensures high precision and repeatability, making it ideal for mass production.

Moreover, plastic injection molding offers significant advantages in terms of efficiency and material usage. The process allows for rapid production cycles, which can drastically reduce lead times compared to traditional manufacturing methods. Additionally, the ability to create complex geometries with minimal waste makes it an environmentally friendly choice. Manufacturers can also select from a vast array of thermoplastics and thermosetting materials to best meet the performance requirements of their products, from lightweight components to high-strength applications. With these fundamentals in place, plastic injection molding remains an essential strategy for companies seeking to innovate and maintain competitiveness in the fast-paced manufacturing landscape.

Key Advantages of Plastic Injection Molding Over Traditional Methods

Plastic injection molding has become a cornerstone of modern manufacturing due to its numerous advantages over traditional production methods. One significant benefit is the efficiency it offers in large-scale production. According to a report by Grand View Research, the global plastic injection molding market size was valued at over $320 billion in 2021, reflecting an annual growth rate of approximately 5.8%. This efficiency stems from the ability to produce thousands of identical parts quickly, which drastically reduces labor costs and production time compared to manual or smaller-scale fabrication methods.

In addition to efficiency, plastic injection molding allows for a higher level of design complexity and precision. The process enables manufacturers to create intricate shapes and fine details that are often challenging to achieve through conventional processes like machining or casting. A study published by the American Injection Molding Institute indicates that the dimensional accuracy of injection-molded parts can achieve tolerances as tight as ±0.001 inches. This precision not only enhances product quality but also minimizes material wastage, making injection molding a more sustainable choice in the long run. As industries seek greater customization and rapid prototyping capabilities, the superior adaptability of plastic injection molding bolsters its status as an essential manufacturing technique.

Applications of Plastic Injection Molding in Various Industries

Plastic injection molding is a versatile manufacturing process that plays a crucial role across various industries. In the automotive sector, it is widely used to produce complex components, such as dashboards, interior trim, and various housings, due to its ability to create intricate designs with high precision. This method not only enhances the performance and aesthetic appeal of vehicles but also contributes to reducing production time and costs, making it essential for meeting the fast-paced demands of the automotive market.

In the consumer goods industry, plastic injection molding is instrumental in producing everyday items like containers, toys, and household appliances. The process allows for high-volume production with consistent quality and detail, ensuring that products meet the expectations of consumers. Furthermore, the technology enables the use of a diverse range of materials, facilitating the creation of lightweight, durable items that are easy to manufacture and assemble. As sustainable practices become increasingly important, innovations in injection molding are leading to the development of eco-friendly materials, further broadening its application and significance in modern manufacturing.

Why Plastic Injection Molding is Essential for Modern Manufacturing Success

| Industry | Application | Material Type | Production Volume (Units/Year) |

|---|---|---|---|

| Automotive | Interior Components | Polypropylene | 5,000,000 |

| Consumer Electronics | Casing and Housings | ABS Plastic | 2,000,000 |

| Medical Devices | Syringes and Containers | Polycarbonate | 1,500,000 |

| Packaging | Containers and Bottles | Polyethylene | 10,000,000 |

| Toys | Playsets and Action Figures | PVC | 3,000,000 |

The Role of Technology in Advancing Injection Molding Techniques

The advancement of technology has drastically transformed the landscape of plastic injection molding, making it a cornerstone of modern manufacturing. Cutting-edge innovations like computer-aided design (CAD) and computer-aided manufacturing (CAM) create intricate models and streamline the injection molding process. These technologies enable manufacturers to optimize mold designs, enhance precision, and reduce production times. As a result, businesses can produce complex components with tighter tolerances and higher efficiency, significantly improving their production capabilities and reducing waste.

Moreover, the integration of automation and robotics into injection molding processes has revolutionized the operational dynamics of manufacturing facilities. Automated systems can perform repetitive tasks with consistency and speed, minimizing human error and enhancing overall safety. This technological synergy not only boosts production rates but also allows for greater flexibility in manufacturing. Companies can quickly adapt to changing market demands and customize products on a larger scale, ensuring they stay competitive in the ever-evolving industrial environment. The role of technology in injection molding techniques continues to expand, paving the way for innovative applications and sustainable practices within the manufacturing sector.

Future Trends and Innovations in Plastic Injection Molding Processes

The field of plastic injection molding is undergoing a significant transformation driven by emerging trends and groundbreaking innovations. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $370 billion by 2025, growing at a CAGR of 3.8% from 2020. This growth is largely attributed to the increasing demand for lightweight, durable materials in various industries, including automotive, consumer goods, and medical sectors. Manufacturers are now investing heavily in automation, incorporating advanced technologies such as robotics and artificial intelligence to enhance efficiency and precision in the injection molding process.

Furthermore, sustainability has become a critical focus, with many companies shifting towards eco-friendly materials and processes. A study from Grand View Research indicates that the bioplastics market is expected to reach $27 billion by 2025, which highlights the industry's transition towards more sustainable practices. Innovations such as 3D printing in conjunction with traditional injection molding are also emerging, allowing for rapid prototyping and customization. This integration not only reduces material waste but also shortens the production cycle, enabling manufacturers to respond swiftly to market demands. These trends indicate a promising future for plastic injection molding, positioning it as a central pillar of modern manufacturing success.

Related Posts

-

Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development

-

How to Choose the Right Plastic Molding Machine for Your Production Needs

-

Understanding the Different Types of Plastic Extruders and Their Applications