Top 10 Benefits of Using Injection Molding Machines in Manufacturing

The use of injection molding machines in manufacturing has revolutionized production processes. According to industry expert John Smith, “Injection molding allows for precision and efficiency that other methods simply cannot match.” This technology brings numerous benefits to manufacturers, making it a preferred choice in various sectors.

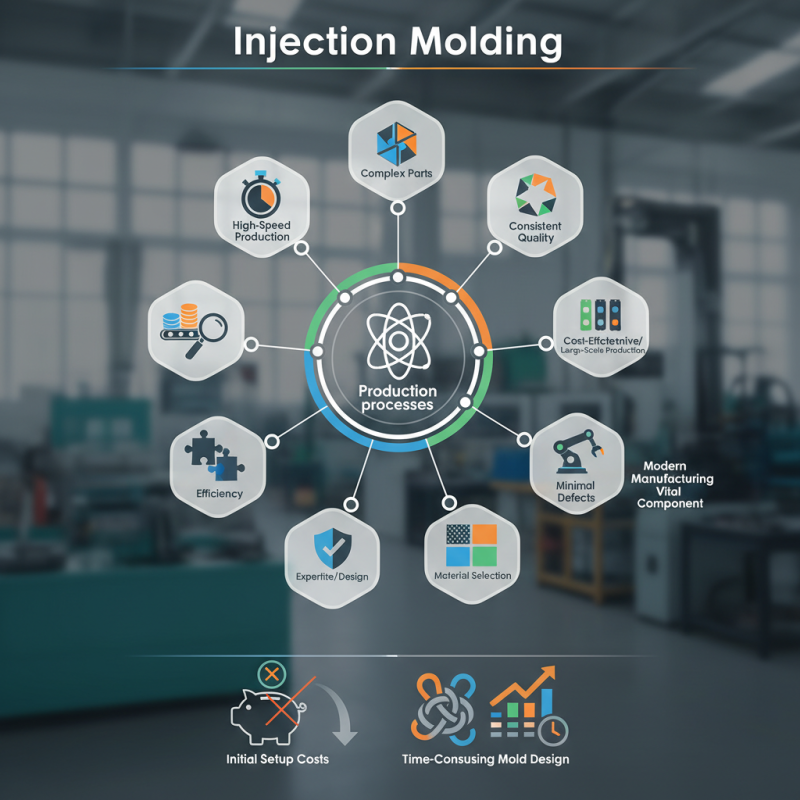

Injection molding machines enable high-speed production of complex parts. These machines can create items with intricate designs and fine details. Manufacturers appreciate that they can achieve consistent quality with minimal defects. Additionally, the cost-effectiveness of large-scale production cannot be ignored. Yet, some companies struggle with initial setup costs, which can be substantial.

While injection molding is efficient, it is not without its challenges. For example, designing molds can be time-consuming and requires expertise. Companies must also be cautious about material selection to avoid performance issues. Nevertheless, the advantages of using injection molding machines make them a vital component in modern manufacturing.

Advantages of Injection Molding Machines for High Production Volumes

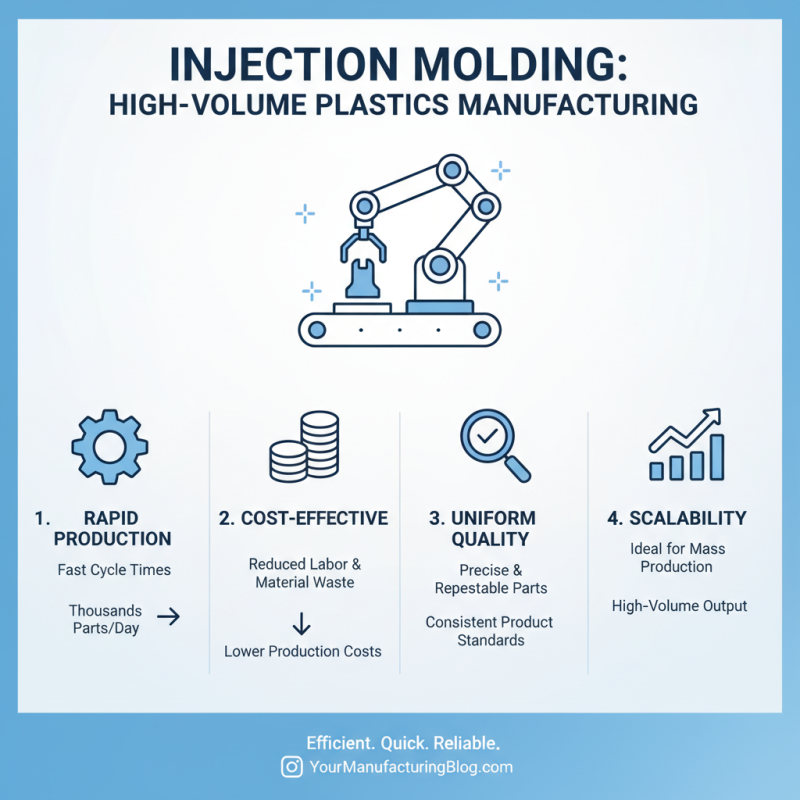

Injection molding machines are essential in manufacturing. They excel in producing large quantities of plastic parts quickly and efficiently. This method is ideal for high production volumes. With fast cycle times, injection molding can output thousands of units in a single day. This efficiency significantly lowers production costs and time.

To optimize your production, consider using advanced materials. Some materials enhance strength and durability, while others improve flexibility. Choosing the right material can lead to better product performance. Experiment with different resin types to find what works best for your designs.

For those looking to innovate, incorporating automation can boost productivity. Automating processes minimizes human error and increases consistency. However, training staff to manage automated systems is crucial. Always be open to adjustments in your workflow. It’s a learning process, and each adjustment can lead to greater efficiency.

Enhanced Design Flexibility with Injection Molding Technology

Injection molding technology significantly enhances design flexibility in manufacturing. This method allows engineers to create intricate shapes that were once difficult to achieve. The versatility of injection molding supports a wide range of materials. Designers can experiment with various polymers, metals, and composites. This adaptability can lead to innovative products that meet specific needs.

With injection molding, the complexity of designs has no bounds. Multi-component designs enable the integration of different functions into one piece. This reduces assembly costs and improves product performance. However, creating these designs requires careful planning. The accuracy of mold design must be perfect to avoid costly errors during production.

Understanding limitations is critical too. Injection molding may not be ideal for very large parts, or small production runs. These aspects deserve attention and reflection. Balancing design ambition with practical constraints is essential for success. Ultimately, the beauty of injection molding lies in its power to combine creativity and functionality.

Cost Efficiency in Material Usage through Injection Molding

Injection molding provides significant advantages in material usage. This manufacturing process offers cost efficiency that many industries seek. According to a report by Grand View Research, injection molding applications are expected to reach $329.5 billion by 2028. This growth highlights the value manufacturers place on this technology.

The ability to recycle materials plays a crucial role in cost savings. Data indicates that about 50% of the material can be reused in subsequent production cycles. This reduces waste and overall expenses. In addition, injection molding often uses less energy compared to traditional methods. The Energy Information Administration notes that injection molding machines are 30% more energy-efficient than other manufacturing processes.

Challenges remain, though. Not all materials can be easily molded, leading to potential waste. The initial setup cost can also deter smaller manufacturers from adopting this method. Furthermore, quality must be continuously monitored to ensure efficiency. Each of these factors requires careful consideration in the manufacturing process, making it essential for companies to balance cost and material efficiency.

Cost Efficiency in Material Usage through Injection Molding

Improved Product Consistency and Quality Control in Manufacturing

Injection molding machines play a critical role in manufacturing, particularly regarding product consistency and quality control. A recent industry report indicates that over 80% of manufacturers using injection molding see improved product repeatability. This technology allows for precise control over material flow and temperature, resulting in uniform products with minimal defects. In contrast, traditional manufacturing methods often yield inconsistent results, creating challenges in meeting customer expectations.

Moreover, the automation inherent in injection molding contributes to quality assurance. Sensors can monitor processes in real-time, ensuring that each cycle meets predefined standards. A study revealed that companies employing these machines reduced defect rates by up to 30%. However, reliance on automated systems can lead to overconfidence. If not regularly calibrated, machines may produce faulty items undetected. Such oversights remind us of the importance of routine checks and maintenance in manufacturing.

Despite these advancements, challenges remain. Variability in raw materials can affect final product quality. Even minor fluctuations can compromise consistency. Manufacturers must invest in high-quality materials and rigorous testing to mitigate these issues. Balancing automation with manual oversight is key. This approach helps maintain high standards without sacrificing production efficiency. It’s a complex yet necessary dance in modern manufacturing.

Reduced Lead Times and Faster Time-to-Market with Injection Molding

Injection molding is a game-changer in manufacturing. One of its main benefits is reduced lead times. According to industry reports, using injection molding can shorten production cycles by 30% to 50%. This efficiency allows companies to respond more quickly to market demands. A project that would typically take weeks can often be completed in days with advanced machines.

The faster time-to-market improves competitiveness. In industries like automotive and consumer goods, every second counts. Companies that embrace injection molding can launch products 20% faster, leading to increased market share. This speed doesn't just mean quicker product availability; it also reduces inventory costs. Holding less stock is a great way to cut overhead.

However, the process isn't without challenges. High initial costs and the need for skilled operators can deter some manufacturers. Companies must weigh these risks against potential gains. The learning curve can be steep for new users. Regular maintenance is critical, too. Neglecting this can lead to longer downtimes. Balancing these factors is essential for success in leveraging injection molding technologies.

Related Posts

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

Why Is Injection Molding the Best Choice for Prototyping and Production

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

-

Why Plastic Injection Molding is Essential for Modern Manufacturing Success

-

Top 10 Tips for Choosing the Best Plastic Injection Molding Machine