Understanding the Different Types of Plastic Extruders and Their Applications

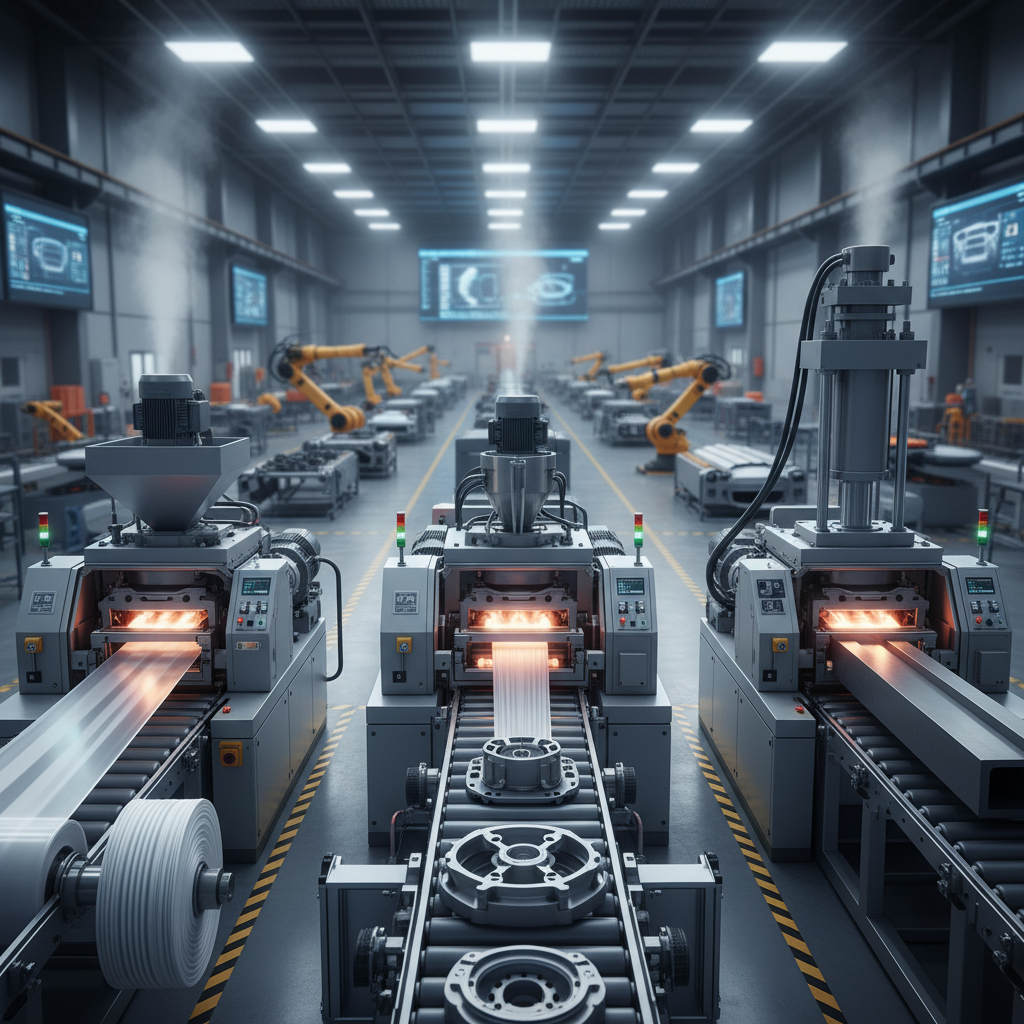

In the world of manufacturing, plastic extruders play a pivotal role in transforming raw materials into a plethora of useful products. These machines are essential for creating various plastic shapes and forms that are integral to numerous industries, including automotive, construction, and consumer goods. According to a report by MarketsandMarkets, the global plastic extrusion market is expected to reach $56.87 billion by 2025, growing at a CAGR of 4.8%. This growth is driven by the increasing demand for lightweight and durable materials, making the understanding of different types of plastic extruders and their applications more crucial than ever.

Industry expert Dr. John Smith, a renowned figure in polymer engineering, once stated, "The versatility of plastic extruders allows manufacturers to innovate and adapt to the changing market needs rapidly." This underscores the importance of knowing the various types of plastic extruders available and their specific applications to maximize efficiency and productivity. Understanding these differences not only aids in selecting the right extruder for a given task but also plays a significant role in optimizing production processes and material usage across various sectors. In this context, we delve into the "Top 10" plastic extruders and their applications, shedding light on their unique functionalities and industry relevance.

Types of Plastic Extruders: A Comprehensive Overview

Plastic extruders are essential machines in the manufacturing industry, transforming raw plastic materials into a variety of shapes and products. Understanding the different types of plastic extruders is crucial for selecting the right equipment for specific applications. The main types include single-screw extruders, twin-screw extruders, and blow mold extruders, each offering unique advantages based on the desired end product.

Single-screw extruders are widely used for their simplicity and cost-effectiveness, making them suitable for applications like film and sheet production. Twin-screw extruders, on the other hand, offer enhanced mixing capabilities and are ideal for compounding and processing materials that require a homogeneous blend. Blow mold extruders focus on hollow products, utilizing air to expand the plastic into specific molds, commonly found in packaging applications.

**Tips:** When choosing a plastic extruder, consider the material properties and the desired production volume. A thorough understanding of the characteristics of polymer materials can lead to better processing results. Additionally, regularly maintaining the extruder can significantly reduce downtime and operational costs, ensuring efficiency in production.

Understanding the Different Types of Plastic Extruders and Their Applications - A Comprehensive Overview

| Type of Extruder | Application | Material Processed | Key Features |

|---|---|---|---|

| Single Screw Extruder | Film, Sheet and Pipe Production | Polyethylene, PVC | Simple design, Efficient for thermoplastics |

| Twin Screw Extruder | Compounding and Masterbatch Production | Nylon, Polycarbonate, ABS | High mixing efficiency, Better control over material properties |

| Single Screw Extruder with Gear Pump | High-precision applications | Polypropylene, PET | Stable output, Excellent melt pressure stability |

| Co-rotating Twin Screw Extruder | Blending and Filling Applications | Polymer Blends, Additives | Enhanced mixing, Versatile processing capabilities |

| Counter-rotating Twin Screw Extruder | Devolatilization and Biopolymer Processing | PLA, PHA | Efficient devolatilization, Suitable for heat-sensitive materials |

Key Features of Single Screw Extruders and Their Uses

Single screw extruders are widely recognized for their efficiency and versatility in the plastic processing industry. These machines typically consist of a single rotating screw housed within a cylindrical barrel, which enables the continuous feeding, melting, and shaping of various thermoplastic materials. According to a report by Grand View Research, the single screw extruder market is expected to reach USD 5.8 billion by 2025, highlighting its critical role in production lines across sectors.

One of the key features of single screw extruders is their adaptability to a range of materials, including polyethylenes, polystyrenes, and polypropylenes. This versatility allows manufacturers to adjust processing parameters such as temperature, screw speed, and feed rate to optimize output and ensure quality. A study by the Polymer Processing Society indicates that effective parameter control can improve throughput by up to 30%, making single screw extruders a preferred choice for large-scale production.

Furthermore, their relatively simple design facilitates easier maintenance and operational efficiency, reinforcing their status as a fundamental component in modern plastic manufacturing.

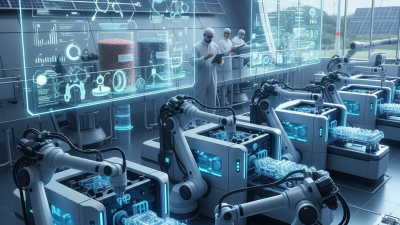

Exploring Twin Screw Extruders: Benefits and Applications

Twin screw extruders are increasingly recognized for their versatility and efficiency in various plastic processing applications. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that allow for better mixing, compounding, and pumping capabilities. This unique design not only enhances the dispersion of additives within the polymer matrix but also facilitates greater control over the material's thermal and mechanical properties. As a result, twin screw extruders are often favored in applications requiring high quality and precision, such as the production of specialty polymers, food packaging materials, and engineering plastics.

The benefits of twin screw extruders extend beyond their operational capabilities. They are well-suited for processing a wide range of materials, including thermoplastics, elastomers, and even biodegradable plastics. Their ability to handle various feed materials permits manufacturers to innovate and create tailored resin formulations that meet specific industry demands. Moreover, the scalability of twin screw extruders allows for easy transition from laboratory-scale formulations to full-scale production, making them an invaluable asset across industries such as automotive, medical devices, and consumer goods. As sustainability becomes increasingly important in material science, twin screw extruders are poised to play a pivotal role in advancing eco-friendly manufacturing processes.

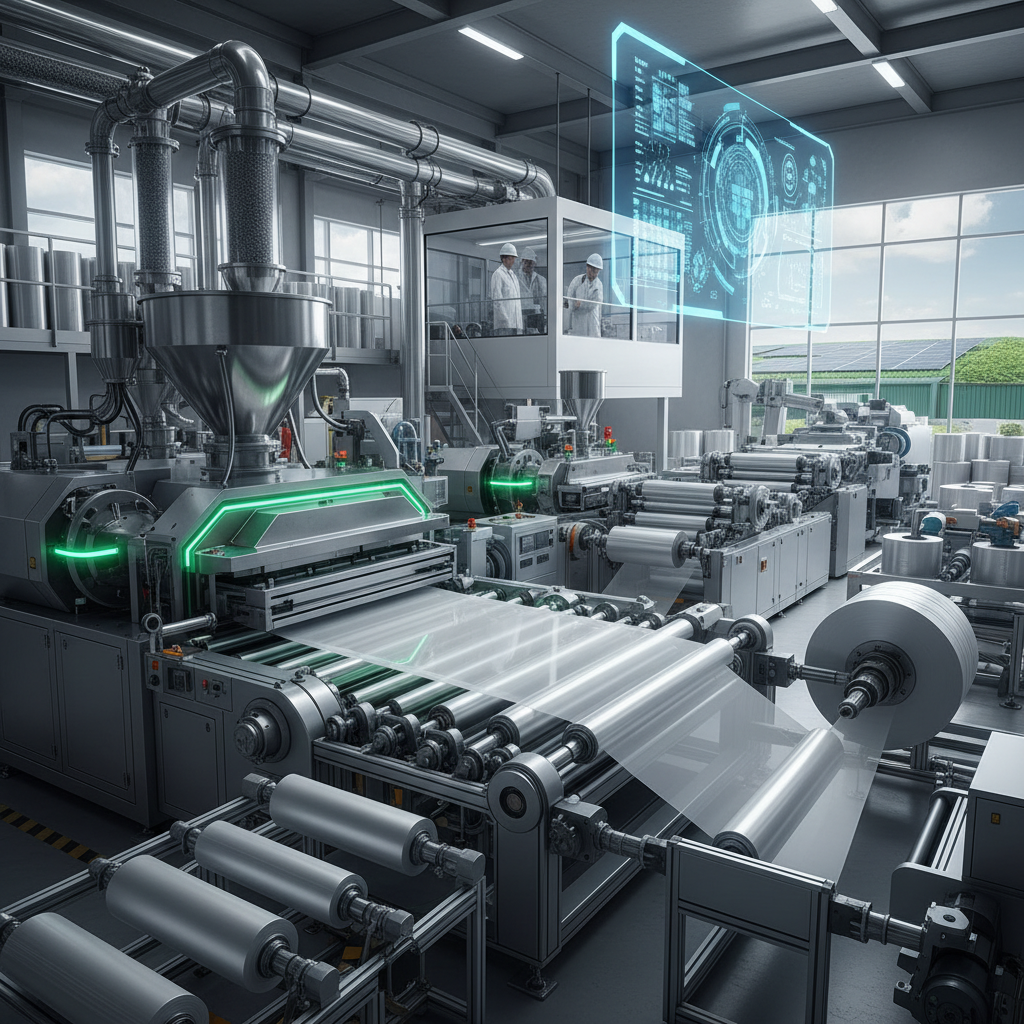

Understanding Sheet and Film Extruders in Plastic Production

In the realm of plastic production, sheet and film extruders play a pivotal role in shaping the industry. Recent advancements highlight this sector's evolution, notably with new technologies aimed at enhancing efficiency and sustainability in production. The global market for plastics extruded is projected to reach USD 259.21 billion by 2034, growing from USD 182.91 billion noted for 2025, indicating a robust demand for innovatively engineered materials.

Kuhne GmbH's recent launch of a U.S. branch underscores a strategic move to expand their footprint in the film and sheet extrusion market. This expansion complements MEAF Machines' unveiling of the Xtender technology at K 2025, which promises to revolutionize the processing of recycled PET for films and sheets. Additionally, advancements in thickness control systems for extruded plastics are emerging, showcasing the industry's commitment to precise manufacturing and quality enhancements.

As industry leaders continue to innovate, the future of sheet and film extrusion seems bright, paving the way for more sustainable practices and increased production capacities.

The Role of Blown Film Extruders in Packaging Solutions

Blown film extruders play a crucial role in the production of packaging materials due to their unique ability to create thin films of plastic. This process involves melting plastic resin and forcing it through a circular die to form a continuous bubble of film. As the film cools and solidifies, it is subsequently flattened and wound into rolls, making it ideal for various packaging needs. The versatility of blown film extruders allows for the production of different film gauges and properties, catering to a wide range of applications, from grocery bags to heavy-duty industrial packaging.

In recent years, advancements in blown film technology have further enhanced its significance in the packaging sector. Innovations such as multi-layer blown film structures enable manufacturers to combine different materials, improving barrier properties and extending shelf life for food products. This has made blown film extruders invaluable in an age where sustainability and efficiency are paramount. Manufacturers can now create films that reduce plastic waste while still offering superior protection, demonstrating the essential role of blown film extruders in modern packaging solutions.

Related Posts

-

Why Plastic Extrusion is the Key to a $300 Billion Manufacturing Sector Growth?

-

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

-

2025 Top 10 Innovations Revolutionizing the Injection Molding Process

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production