Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023

In the fast-evolving landscape of manufacturing, understanding plastic injection tooling is critical for driving efficiency and reducing production costs. According to a report by MarketsandMarkets, the plastic injection molding market is projected to reach $370.41 billion by 2026, growing at a CAGR of 5.3%. This growth underscores the importance of optimizing the tooling process, as advanced tooling designs can significantly reduce cycle times and enhance product quality. Efficient plastic injection tooling not only minimizes waste but also maximizes production throughput, which is essential for industries aiming to stay competitive. As manufacturers increasingly adopt automation and smart technologies, the role of precise and innovative tooling solutions becomes more pronounced, making it imperative for businesses to invest in high-quality plastic injection tooling to meet the rising demands of the market.

Key Considerations for Selecting the Right Plastic Injection Tooling for Your Production Needs

When selecting the right plastic injection tooling for your production needs, several key considerations can significantly enhance manufacturing efficiency in 2023. One major factor is the integration of advanced technologies such as intelligent data-driven systems that leverage reinforcement learning and knowledge graphs. These innovations allow for personalized optimization in mold manufacturing, ensuring that the tooling is tailored precisely to meet specific production requirements.

Tips for selecting tooling include evaluating the impact of energy-efficient models, which have been increasingly developed to reduce operational costs. Additionally, consider the market trends indicating a growing demand in industries like automotive and packaging, which can influence the choice of materials and design for injection molds. It's essential to choose tools that not only meet current needs but are also adaptable to future market demands.

Furthermore, staying informed about market projections is crucial. The global injection molding machines market is expected to show substantial growth, making it vital to select tools that align with long-term business goals. By prioritizing advanced tooling solutions and understanding industry trends, manufacturers can optimize their production processes and drive efficiency.

Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023 - Key Considerations for Selecting the Right Plastic Injection Tooling for Your Production Needs

| Consideration | Description | Impact on Efficiency | Example Tools |

|---|---|---|---|

| Material Selection | Choosing the right plastic type based on application requirements. | Improves part strength and reduces waste. | ABS, Polypropylene, Nylon |

| Tool Design | The configuration and details of the mold design. | Enhances cycle time and precision of parts. | Hot runner, Cold runner systems |

| Machining Tolerances | Precision in mold creation for consistency. | Reduces rework and improves product quality. | CNC machining, EDM |

| Production Volume | Determining the quantity of units produced over time. | Affects cost per part and tool lifecycle. | Short-run vs Long-run tools |

| Maintenance Plan | Scheduled upkeep and servicing of tools. | Extends tool life and reduces downtime. | Preventive vs Predictive Maintenance |

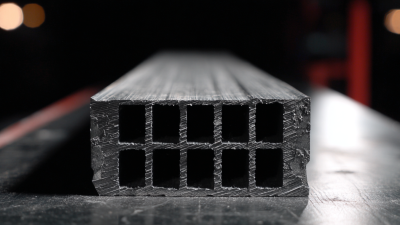

Innovative Materials in Plastic Injection Tooling: Improving Durability and Reducing Costs

In 2023, the landscape of plastic injection tooling is evolving rapidly, mainly due to the innovative materials that are being integrated into manufacturing processes. Recent industry reports indicate that utilizing advanced materials, such as carbon fiber-reinforced polymers and high-performance thermoplastics, has the potential to enhance the durability of molds by up to 30%, while also reducing overall production costs by 15% or more. These materials not only prolong the tool lifespan but also facilitate faster cycle times, which is essential for meeting the increasing demand for high-quality plastic products.

Tips for Manufacturers: Consider transitioning to innovative materials that provide superior strength and thermal resistance. This change can lead to significant savings in both maintenance and material costs, improved product quality, and a more sustainable manufacturing process.

Furthermore, the adoption of additive manufacturing techniques in producing tooling components is being embraced to optimize efficiency. Reports suggest that companies employing 3D printing for molding parts can achieve lead times reduced by 50% compared to traditional methods. This agility in manufacturing aligns with the current market trend towards customization and rapid prototyping, allowing manufacturers to respond swiftly to client demands.

Tips for Implementation: Invest in training staff on the latest 3D printing technologies to ensure that your team can leverage these advancements effectively, making your production processes not just faster, but more flexible and adaptive to changes in the market.

Implementing Advanced Technologies in Injection Molding: Automation and Its Impact on Efficiency

The injection molding industry is at the forefront of technological advancements, with automation playing a crucial role in enhancing manufacturing efficiency. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach $345.2 billion by 2023, driven significantly by the adoption of automated systems. Automation in injection molding encompasses the use of robotics and smart manufacturing technologies, which streamline production processes and minimize human error, resulting in higher output rates and improved quality control.

Incorporating advanced technologies such as Industry 4.0 principles—IoT, AI, and machine learning—has transformed traditional practices. A study published by Deloitte highlights that manufacturers implementing automation can achieve efficiency gains of up to 30% while reducing operational costs by approximately 20%. These innovations not only enhance the speed and precision of the injection molding process but also provide real-time data analytics, enabling manufacturers to optimize workflows and anticipate maintenance needs. As the industry embraces these advancements, the focus on enhancing efficiency through automation will remain a pivotal factor in maintaining competitiveness in 2023 and beyond.

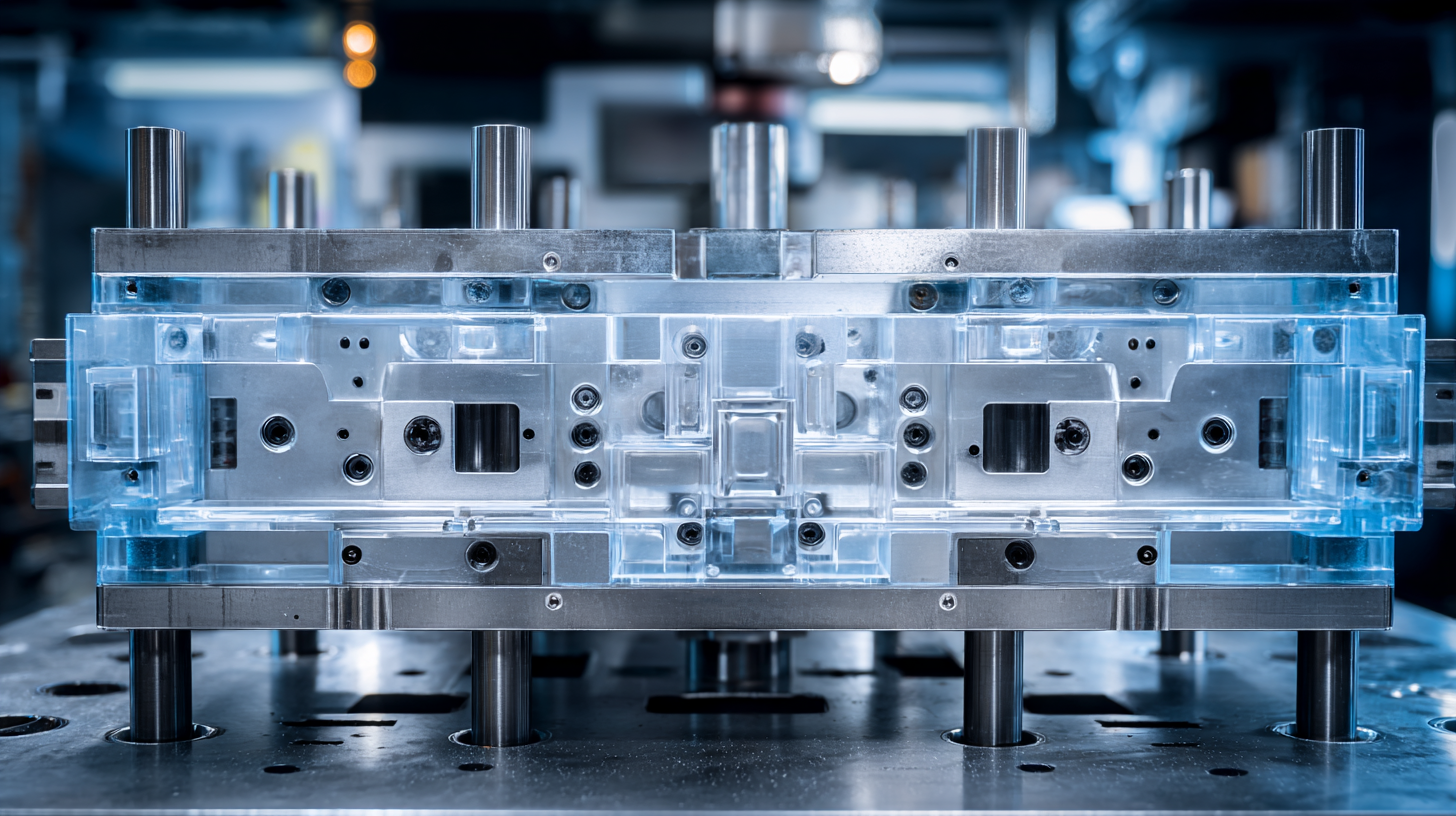

Understanding the Design Process of Injection Mold Tools: Best Practices for Optimal Performance

The design process of injection mold tools is crucial for achieving optimal performance in manufacturing. A well-structured approach can significantly enhance product quality and reduce cycle times. First and foremost, a thorough understanding of the product requirements and material properties is essential. This allows designers to tailor the mold design to suit specific needs, whether it's for intricate details or robust components.

**Tip:** Always engage in iterative design processes. Prototype and test different designs to evaluate performance before finalizing the tooling. This not only minimizes costly errors but also improves the overall efficiency of the manufacturing process.

In addition, incorporating features such as cooling channels and venting systems can drastically improve cycle times and product consistency. Designers should focus on creating molds that facilitate rapid heat transfer and promote effective air escape during the injection process.

**Tip:** Utilize simulation software to predict flow characteristics and identify potential issues during the design phase. This proactive approach will save time and resources, ensuring that the final mold performs at its best.

By adhering to these best practices, manufacturers can optimize their injection molding processes, leading to improved efficiency and product quality in 2023.

Measuring the ROI of Upgrading Injection Tooling: Industry Benchmarks and Performance Metrics

Upgrading injection tooling is crucial for manufacturers looking to optimize production efficiency and enhance product quality in 2023. To measure the return on investment (ROI) of these upgrades, it is essential to establish industry benchmarks and performance metrics. A well-defined ROI framework typically includes parameters such as cycle time reduction, scrap rate improvement, and enhanced dimensional accuracy. By closely monitoring these metrics, manufacturers can identify the direct financial benefits arising from their tooling investments.

For instance, a reduction in cycle time can lead to increased output without the need for additional resources, directly impacting profitability. Additionally, minimizing scrap rates not only saves material costs but also enhances sustainability efforts, aligning production practices with environmental standards. Companies should regularly assess their performance against industry benchmarks to gauge the effectiveness of their tooling upgrades. This systematic approach enables manufacturers to make informed decisions, ensuring that their investments in injection tooling yield significant and measurable returns.

Related Posts

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability