2025 Top 10 Innovations Revolutionizing the Injection Molding Process

The injection molding process has long been a cornerstone of manufacturing, enabling the efficient production of complex plastic parts across various industries. As we approach 2025, rapid advancements in technology are set to transform this traditional method into a more streamlined and innovative practice. This article explores the top 10 innovations that are revolutionizing the injection molding process, showcasing how these breakthroughs are enhancing efficiency, reducing costs, and improving product quality.

In this rapidly evolving landscape, key innovations such as automation, advanced materials, and digital integration are driving significant changes. These advancements not only optimize production cycles but also ensure sustainability and adaptability in manufacturing practices. By embracing these cutting-edge technologies, manufacturers can achieve greater precision and flexibility, ultimately leading to a more competitive edge in the market.

As we delve into the details of these innovations, we will uncover how they are reshaping the injection molding process for the future. From the integration of artificial intelligence to the development of eco-friendly materials, the next wave of innovations promises to redefine not just the process itself, but also the very possibilities of what can be achieved in manufacturing.

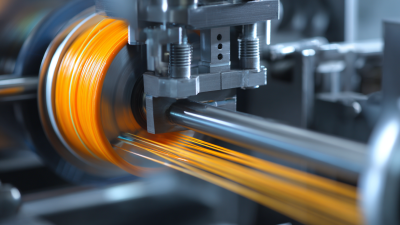

Revolutionary 3D Printing Integration in Injection Molding Processes

The integration of revolutionary 3D printing technologies into injection molding processes is poised to transform the manufacturing landscape significantly. As we look forward to 2025, 3D printing is expected to play a crucial role in enhancing design flexibility and reducing production lead times. Techniques like Continuous Fiber Injection Processing (CFIP) enable the reinforcement of 3D printed components with continuous fibers, offering unprecedented strength and durability. This innovation not only improves the performance of molded parts but also aligns with the growing demand for sustainable manufacturing practices.

Moreover, the combination of low-pressure injection molding with 3D printing allows for a more efficient production of complex geometries, reducing material waste and energy consumption. As industries strive to embrace smart manufacturing and sustainability, the adoption of 3D printing within injection molding becomes increasingly critical. By 2030, the anticipated growth of the 3D printing sector, projected to surpass $40 billion, underscores the transformative potential of these technologies in making injection molding a more agile and eco-friendly process.

2025 Innovations Revolutionizing Injection Molding Process

Smart Sensors Enhancing Real-Time Monitoring and Quality Control

The automotive sector is witnessing transformative changes, particularly through the integration of smart sensors focused on enhancing real-time monitoring and quality control. These advanced sensors enable manufacturers to closely monitor air quality within vehicle cabins, providing real-time data that can lead to significant improvements in user experience and safety. As the automotive cabin air quality sensor market is projected to grow from $849.2 million in 2025 to $1.4215 billion by 2032, the demand for sophisticated monitoring solutions continues to rise.

Tips for implementing smart sensors effectively include ensuring that your sensors are calibrated correctly for accuracy and responsiveness. Furthermore, leveraging data analytics can enhance the effectiveness of these sensors by identifying trends over time and enabling proactive measures to mitigate risks related to air quality.

Additionally, as technology evolves, the integration of Edge AI with smart sensors can facilitate real-time processing of data, making monitoring systems more efficient. This synergy not only optimizes the manufacturing process but also significantly contributes to maintaining high standards of product quality and safety in automotive applications.

Sustainable Materials Transforming the Eco-Friendliness of Injection Molding

Sustainable materials are at the forefront of transforming the injection molding process, making it more eco-friendly than ever before. According to a recent report by Smithers Pira, sustainable materials are projected to account for 40% of the global injection molding market by 2025. This shift is driven by rising environmental concerns and the strict regulations imposed on waste management and carbon emissions.

Biopolymers, recycled plastics, and biodegradable materials are being integrated into manufacturing processes, significantly reducing the ecological footprint of injection molding.

Tips: When choosing sustainable materials, consider the lifecycle assessment of your products to understand their environmental impact better. Look for certifications that verify the sustainability of materials to ensure compliance with eco-friendly practices.

Moreover, manufacturers are adopting innovative methods such as using advanced composite materials, which not only enhance product performance but also facilitate the use of recycled content. As highlighted in a report by Mordor Intelligence, the adoption of recycled plastics in injection molding can cut production costs by up to 20%, all while maintaining high quality and durability. This innovation not only helps in waste reduction but also caters to an increasingly eco-conscious consumer base.

Tips: Collaborate with suppliers who specialize in sustainable materials to stay updated on new options and innovations that can enhance your production capabilities.

AI-Driven Predictive Analytics for Optimizing Production Efficiency

As the injection molding industry continues to evolve, AI-driven predictive analytics is becoming a game-changer in optimizing production efficiency. Recent reports from the International Plastics Association indicate that manufacturers who implement predictive analytics have seen a 20-30% reduction in downtime. This technology utilizes machine learning algorithms to analyze historical data, identify patterns, and forecast potential machine failures before they occur, thus minimizing disruptions in the production line.

Moreover, AI-driven solutions can optimize maintenance schedules based on actual usage and performance metrics, rather than relying solely on predetermined timelines. For instance, a case study conducted by Deloitte found that factories using advanced analytics achieved a 15% increase in overall equipment effectiveness (OEE). This not only leads to cost savings but also allows for a more agile production process that can quickly adapt to market demands.

Tip: To effectively harness predictive analytics, invest in a robust data infrastructure that can collect real-time information from every stage of the injection molding process. This foundation will facilitate more accurate predictions and improve decision-making.

Tip: Train your workforce in data interpretation and the use of AI tools, as fostering a tech-savvy environment is crucial to fully realize the benefits of predictive analytics in injection molding operations.

Advanced Robot Automation Streamlining the Injection Molding Workflow

The injection molding process has seen significant advancements, particularly through the integration of advanced robot automation. These innovations streamline workflows, reduce cycle times, and ensure consistency in production. By employing robotic systems, manufacturers can not only enhance precision but also minimize manual labor, leading to a more efficient and safer working environment. Automation is transforming traditional methods, allowing for rapid adaptation to changing demands without compromising quality.

Tip: When considering automation for your injection molding processes, evaluate the specific tasks that can be optimized. Tasks such as loading, unloading, and quality inspections are prime candidates for robotic solutions, enhancing both speed and accuracy.

Furthermore, advanced automation systems enable real-time monitoring and data collection, providing insights into production trends and potential bottlenecks. This data-driven approach not only aids in immediate problem-solving but also supports long-term continuous improvement initiatives.

Tip: Implementing a modular robotic system can provide flexibility. These systems can be reconfigured easily to accommodate different molds and products, ensuring your investment remains relevant as market demands evolve.

Related Posts

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

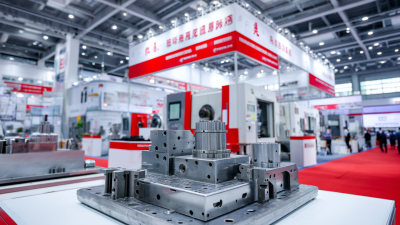

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair