Understanding the Benefits of Prototype Injection Molding for Fast Product Development

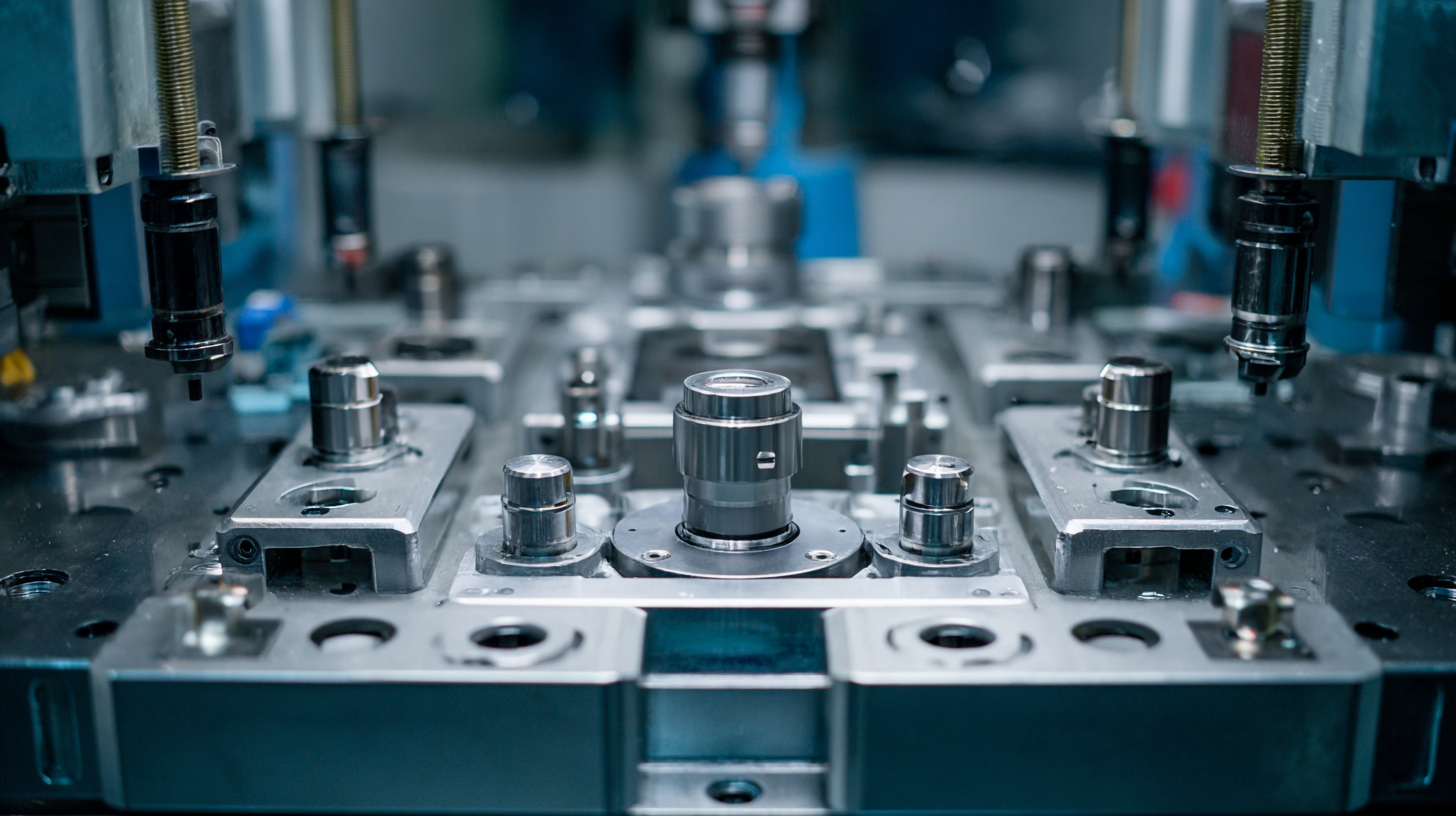

In the fast-paced world of product development, businesses are continually seeking innovative approaches to enhance efficiency and reduce time to market. One such method gaining popularity is prototype injection molding, a powerful technique that allows companies to create high-quality prototypes rapidly and economically. This process not only provides tangible models for testing and evaluation but also facilitates early design iterations, ensuring that products meet market demands more effectively.

By embracing prototype injection molding, organizations can significantly cut development costs while maintaining the ability to refine their designs through real-world feedback. As we delve into the myriad benefits of this technique, it becomes clear how prototype injection molding serves as a cornerstone for achieving accelerated product development in today’s competitive landscape.

Advantages of Prototype Injection Molding in Accelerating Product Development

Prototype injection molding offers significant advantages in accelerating product development, especially in the fast-paced landscape of modern manufacturing. By enabling rapid design iterations, companies can quickly transition from concept to tangible prototypes, allowing for timely testing and feedback. Recent advancements highlight the integration of 3D printing technologies in prototype injection molding, where techniques such as Stereolithography (SLA) have been crucial in developing microfluidic devices. These devices are pivotal in the pharmaceutical and biomedical sectors, streamlining the process from development to quality control.

Moreover, as industries increasingly gravitate towards sustainable practices, the synergy between prototype injection molding and 3D printing facilitates eco-friendly solutions. For instance, the application of 3D-printed molds allows companies to produce nearly indistinguishable prototypes that mirror final products, thereby reducing waste and production time.

According to industry reports, rapid prototyping technologies can cut product development timelines by over 50%, enabling manufacturers to bring innovative designs to market with unprecedented speed. This combination of efficiency and innovation positions prototype injection molding as a vital strategy for companies aiming to stay competitive and responsive to market demands.

Key Factors to Consider When Utilizing Prototype Injection Molding

When utilizing prototype injection molding for fast product development, several key factors must be taken into consideration to ensure the process is efficient and effective. One primary aspect is material selection. According to a report by Grand View Research, the global injection molded plastics market is expected to reach $440 billion by 2025, indicating that choosing the right material can significantly impact the quality and durability of your prototypes. Common materials such as ABS and polycarbonate offer different benefits, from strength to flexibility, and selecting the best one for your project is crucial.

Another critical consideration is mold design. A well-designed mold can greatly reduce production time and costs. Consider the insights from a study published in the Journal of Manufacturing Processes, which states that optimizing mold designs can lead to a 20-30% reduction in cycle times. Investing time in initial design and simulation can yield better prototype outcomes and enhance the overall development process.

**Tip:** Always begin with a thorough design review and simulation to identify potential issues before moving to production.

Furthermore, communication with your injection molding partner can streamline the development process. Establishing clear expectations and timelines will help in avoiding misunderstandings and delays. Ensure that your partner has a proven track record with prototypes in your industry, as this can dramatically reduce trial and error phases.

**Tip:** Regular check-ins during the development phase can help navigate challenges swiftly and keep the project on track.

Benefits of Prototype Injection Molding for Fast Product Development

This chart illustrates the perceived benefits of prototype injection molding in various key areas such as cost efficiency, speed to market, design flexibility, material variety, and quality assurance. Each benefit is rated on a scale from 1 to 10, highlighting the strengths of this approach in fast product development.

Cost-Effectiveness of Prototype Injection Molding for Rapid Prototyping

Prototype injection molding offers a remarkable cost-effective solution for rapid prototyping in product development. According to a report by the Plastics Industry Association, the global market for prototype injection molding is expected to grow by 7.9% annually, reflecting the increasing demand for quick and efficient product testing and development. This process allows manufacturers to create high-quality prototypes in a shorter timeframe, significantly reducing the overall costs associated with traditional manufacturing methods.

One of the standout benefits of prototype injection molding is its ability to produce parts that are not only functional but also accurate to the final product specifications. A study by Grand View Research indicates that utilizing prototype injection molding can decrease development timelines by approximately 50%. By enabling designers to iterate on their concepts quickly, businesses can avoid the expenses tied to prolonged development cycles and extensive revisions. This fosters a faster go-to-market strategy, which is crucial in industries where timing can dictate market success.

Maximizing Efficiency with Advanced Materials in Injection Molding

Advanced materials play a crucial role in enhancing efficiency in prototype injection molding, a method renowned for its speed and precision in product development. Utilizing high-performance polymers and composites can significantly improve the mechanical properties of the prototypes, allowing for more robust and lighter designs. These advanced materials not only reduce cycle times during production but also facilitate the creation of complex geometries that would be challenging with traditional manufacturing processes. As a result, engineers and designers can iterate their designs more rapidly, leading to faster time-to-market and increased competitive advantage.

Moreover, the integration of advanced materials in injection molding enables better thermal stability and chemical resistance, catering to a broader range of applications across industries. For instance, the use of thermoplastic elastomers can enhance flexibility and durability, making prototypes suitable for rigorous testing in real-world conditions. This adaptability ensures that the prototypes are not only representative of the final product but also undergo practical assessments during the development phase, leading to more informed decision-making and refinement of designs before mass production begins. By embracing these innovative materials, companies can streamline their product development processes while ensuring high-quality outputs that meet market demands.

Understanding the Benefits of Prototype Injection Molding for Fast Product Development - Maximizing Efficiency with Advanced Materials in Injection Molding

| Benefit | Description | Material Used | Development Time (Weeks) | Cost Efficiency |

|---|---|---|---|---|

| Rapid Prototyping | Allows testing of designs quickly before full-scale production. | Nylon 6 | 2-3 | High |

| Design Flexibility | Facilitates modifications and design changes during the prototype phase. | ABS Plastic | 3-4 | Moderate |

| High Precision | Provides accurate parts that are close to the final product. | Polycarbonate | 4-5 | High |

| Material Variety | Offers a wide range of material choices for different properties. | Silicone | 2-3 | Moderate |

| Cost-Effective | Reduces overall costs compared to traditional methods. | Polypropylene | 1-2 | Very High |

Tips for Selecting the Right Injection Molding Partner for Prototyping

When embarking on a fast product development journey, selecting the right injection molding partner for prototyping is critical to success. A capable partner will not only bring technical expertise but also a deep understanding of your design requirements and target market. Start by assessing their experience in your specific industry. A partner with a proven track record in producing prototypes similar to your product can provide invaluable insights and accelerate the development process.

Communicating effectively with potential partners is also essential. Before making a decision, inquire about their prototyping techniques and technology capabilities. This is crucial because advanced equipment can influence both the quality of the prototype and the speed of production. Additionally, consider their commitment to quality assurance. A reliable partner will have strict quality controls in place and be willing to share their testing procedures to ensure that the prototypes meet your specifications and standards.

Lastly, evaluate their ability to provide ongoing support throughout the prototyping process. A responsive partner who is open to collaboration can adapt to changes swiftly and help refine your design. Look for partners that offer flexible terms and a collaborative approach, which can facilitate smoother project execution and lead to a successful end product.

Related Posts

-

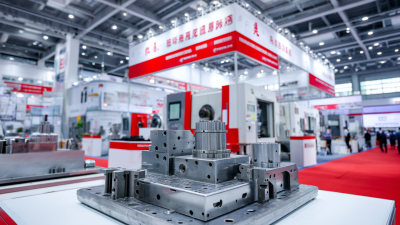

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing