Top 5 Benefits of Using Plastic Molding in Modern Manufacturing Processes

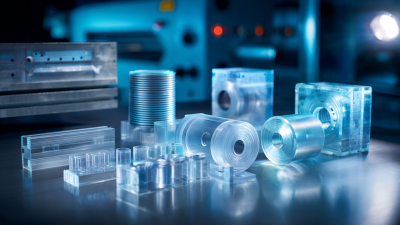

In the rapidly evolving landscape of modern manufacturing, plastic molding has emerged as a pivotal technique that drives efficiency and innovation. According to industry expert Dr. Emily Carter, a leading figure in the field of polymer science, "The adaptability and precision of plastic molding not only enhance production speed but also allow for greater design flexibility." This insight underscores the transformative potential of plastic molding in today’s manufacturing processes, where the demand for high-quality, cost-effective solutions is ever-increasing.

As businesses seek to stay competitive in a global market, the advantages of incorporating plastic molding into their production strategies become unmistakable. From reducing material waste to enabling intricate designs that were previously unattainable, plastic molding paves the way for more sustainable and functional products. By focusing on the top benefits of this manufacturing method, we can better understand its vital role in advancing production capabilities and responding to consumer needs in 2025 and beyond. Embracing these innovations not only supports operational excellence but also propels manufacturers toward a more eco-friendly future.

Advantages of Cost Efficiency in Plastic Molding Compared to Traditional Methods

In today’s manufacturing landscape, plastic molding has emerged as a cost-effective alternative to traditional production methods. The efficiency of plastic molding not only streamlines production timelines but also significantly reduces material waste. Traditional manufacturing techniques often require extensive labor and time, leading to higher overhead costs. In contrast, plastic molding allows for automated processes that can rapidly produce consistent parts, lowering labor costs and increasing production rates.

Moreover, the versatility of plastic molding methods, such as injection molding and blow molding, further enhances cost efficiency. These techniques can accommodate complex designs and large volumes, eliminating the need for expensive machining setups common in traditional manufacturing. This adaptability means manufacturers can respond quickly to market demands without incurring substantial expenses, making plastic molding a smart choice for businesses looking to optimize their production processes while maintaining financial prudence.

Enhancement of Production Speed Through Advanced Plastic Molding Techniques

In the rapidly evolving realm of modern manufacturing, the enhancement of production speed through advanced plastic molding techniques has emerged as a pivotal advantage. According to a report by the Society of Plastics Engineers, the implementation of innovative plastic molding methods can increase production efficiency by up to 30%. These techniques allow manufacturers to produce complex components at a significantly faster rate, minimizing lead times and maximizing resource utilization.

Advanced injection molding, for instance, utilizes real-time monitoring and automation to facilitate quicker cycle times. Data from the Plastics Industry Association indicates that businesses adopting automated molding processes can reduce cycle times by 20-50%, thereby enhancing throughput without compromising product quality. Moreover, such advancements in technology enable manufacturers to respond swiftly to market demands, allowing for more frequent updates in design and an increase in the variety of offerings. In this competitive landscape, leveraging these sophisticated plastic molding techniques is essential for maintaining a robust production tempo and achieving overall operational excellence.

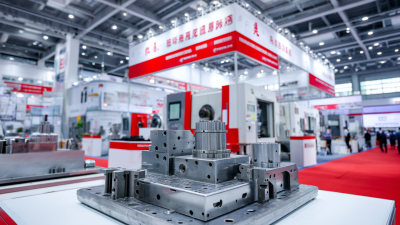

Diverse Applications of Plastic Molding Across Multiple Industries

Plastic molding technology is increasingly becoming a cornerstone in various industries, showcasing its versatility across numerous applications. In the automotive sector, high melt strength polypropylene (HMS PP) is gaining traction due to its lightweight properties and cost-effectiveness, making it the preferred choice for components such as interior panels and structural parts. The automotive industry’s demand for this material is expected to contribute significantly to its growth, with market projections estimating an increase from $177.9 billion in 2025 to $239.4 billion by 2032.

In addition to automotive applications, plastic molding plays a crucial role in sectors like packaging, healthcare, and construction. The diverse manufacturing processes including injection molding, blow molding, and extrusion provide tailored solutions that meet specific performance requirements for various products. For instance, innovative materials such as nylon, or polyamide, are revolutionizing the production of durable goods, while specialized plastic alloys, like PPO/PS, are expanding possibilities in electronic and consumer products. As industries continue to adopt advanced plastic molding techniques, the potential for growth and innovation remains substantial across multiple sectors.

Top 5 Benefits of Using Plastic Molding in Modern Manufacturing Processes

The Role of Plastic Molding in Reducing Waste in Manufacturing Processes

Plastic molding has emerged as a pivotal technique in modern manufacturing, particularly in its role in waste reduction. By utilizing advanced molding technologies, manufacturers can produce highly intricate components with minimal excess material. This efficiency not only conserves resources but also significantly lowers production costs, allowing companies to allocate their budgets more effectively.

One notable event highlighting the innovations in this field is the upcoming Plastics & Rubber Indonesia exhibition, scheduled from November 19-22, 2025. This exhibition serves as a platform for showcasing cutting-edge machinery, materials, and processing technologies that emphasize sustainable practices. As industries gather to collaborate and inspire, the emphasis on reducing waste through improved manufacturing processes is expected to take center stage.

**Tip:** Consider adopting precision molding techniques to minimize scrap and optimize material usage. Further, integrating recycling processes within plastic molding can also enhance sustainability efforts. Evaluating the entire supply chain for waste reduction opportunities can lead to significant improvements in efficiency and environmental impact.

Improved Design Flexibility and Customization Opportunities with Plastic Molding

Plastic molding offers remarkable design flexibility and customization opportunities that modern manufacturing processes greatly benefit from. With plastic's adaptability, manufacturers can create intricate shapes and tailored designs to meet specific needs. This is particularly advantageous in industries like healthcare, where customized 3D-printed prosthetics provide patients with better fitting solutions that are both cost-effective and expedient. The ability to rapidly prototype and modify designs ensures that products can be optimized for performance and user satisfaction.

Tips: When considering plastic molding for your next project, focus on the material selection that aligns with your design requirements. Materials such as thermoplastics or elastomers can offer various properties suitable for different applications. Additionally, leveraging advanced technologies like ultraviolet curing can expedite the mold-making process, allowing for quicker turnarounds and enabling the use of complex designs that enhance product functionality.

As the demand for customized solutions grows across various sectors, the importance of design flexibility in plastic molding cannot be overstated. Companies should explore innovative approaches and equipment that enhance their production capabilities while catering to the ever-evolving market trends. Embracing this technology not only elevates product quality but also strengthens market competitiveness.

Top 5 Benefits of Using Plastic Molding in Modern Manufacturing Processes - Improved Design Flexibility and Customization Opportunities with Plastic Molding

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Design Flexibility | Allows for complex shapes and designs that would be difficult or impossible with other manufacturing methods. | Reduces design constraints, leading to innovative product solutions. |

| Cost Efficiency | Lower material and labor costs due to reduced waste and streamlined production processes. | Increases overall profitability through reduced overhead. |

| Customization Options | Facilitates the production of tailored products to meet specific customer requirements. | Enhances customer satisfaction and market competitiveness. |

| Speed of Production | Rapid production times compared to traditional manufacturing methods. | Faster time-to-market for new products. |

| Durability and Strength | Produces parts that are often lighter yet stronger than those made from metals or ceramics. | Improves product lifespan and reduces the need for frequent replacements. |

Related Posts

-

10 Essential Tips for Working with Injection Moldable Plastics

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Understanding Plastic Injection Tooling: The Key to Optimizing Manufacturing Efficiency in 2023

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair