How to Create High Quality Injection Molded Parts in 2025

In the rapidly evolving landscape of manufacturing, the production of high-quality injection molded parts is becoming increasingly crucial. As we look towards 2025, industry experts highlight the necessity of adopting advanced techniques and technologies to enhance efficiency and product quality. Dr. Emily Chen, a leading expert in injection molding, states, “The future of injection molded parts lies in innovation, precision, and the ability to anticipate market demands.” Her insights underline a pivotal shift in how manufacturers must approach production processes.

With the integration of smart technologies such as AI and machine learning, the methods of designing and creating injection molded parts are set to transform dramatically. These technologies not only promise to reduce waste but also improve consistency in quality, which has historically been a challenge in the industry. As companies strive to meet the expectations of an increasingly discerning market, understanding the fundamental principles that govern the creation of these parts will be key to successful outcomes.

As we delve into the methodologies for crafting high-quality injection molded parts, it becomes evident that collaboration across engineering, design, and manufacturing disciplines will be essential. By harnessing the collective expertise of the industry and embracing a culture of continuous improvement, manufacturers can look forward to a new era of precision and excellence in injection molded parts production.

Understanding Injection Molding: An Overview of the Process in 2025

Injection molding is a widely used manufacturing process that enables the production of complex plastic parts with high precision and efficiency. In 2025, the process continues to evolve, integrating advanced technologies such as automation, artificial intelligence, and improved material formulations. The primary steps in injection molding include material preparation, injection of the molten material into a mold cavity, cooling, and ejection of the finished part. By ensuring optimal temperature control and pressure during these stages, manufacturers can enhance the quality and consistency of the molded components.

The injection molding process begins with the careful selection and preparation of raw materials, typically plastic resins. These materials undergo heating until they reach a molten state before being injected into specially designed molds. In recent years, innovations in mold design have allowed for faster cooling and shorter cycle times, significantly impacting production efficiency. Additionally, incorporating smart sensors and data analytics throughout the injection process has paved the way for real-time monitoring and adjustments, leading to improved product quality and reduced waste.

As manufacturers strive to meet rising demand for high-quality, sustainable products, the development of biodegradable and recycled materials is gaining momentum in the injection molding sector. This shift not only addresses environmental concerns but also opens up new avenues for innovation. As we look toward 2025, understanding these advancements in injection molding is crucial for optimizing production processes and ensuring the delivery of high-quality parts that meet the needs of various industries.

Key Advantages of High-Quality Injection Molded Parts in Modern Manufacturing

In modern manufacturing, the demand for high-quality injection molded parts continues to rise, driven by the need for efficiency, precision, and durability. High-quality injection molded components play a pivotal role in various industries, including automotive, aerospace, and consumer electronics. A recent industry report indicated that the global injection molding market is expected to reach approximately $320 billion by 2025, highlighting the growing significance of advanced molding technologies that produce superior parts.

One of the key advantages of high-quality injection molded parts is their ability to reduce production costs and cycle times significantly. Advanced materials and processing technologies enable manufacturers to produce complex geometries with tight tolerances, thereby minimizing waste and enhancing product performance. Data suggests that manufacturers adopting state-of-the-art injection molding techniques can achieve a 30% reduction in labor costs while increasing production efficiency by up to 40%. This shift not only accelerates time-to-market but also improves product quality, leading to higher customer satisfaction and reduced return rates.

Moreover, the sustainability aspect of high-quality injection molded parts cannot be overlooked. With an increasing emphasis on eco-friendly manufacturing, the adoption of recyclable materials and energy-efficient processes has become essential. Reports indicate that the use of such materials in injection molding can lead to a 50% decrease in carbon emissions compared to traditional methods. As industries move toward greener practices, the integration of high-quality injection molded components will be vital in driving innovation while meeting environmental standards.

Materials Used in Injection Molding: Trends and Innovations for 2025

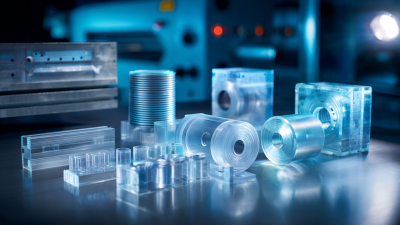

In 2025, the landscape of materials used in injection molding is set to experience significant transformation driven by innovations and sustainability. A major trend is the increased adoption of bio-based and recyclable materials that reduce the environmental impact of manufacturing. Materials such as biodegradable plastics and biopolymers are gaining traction, offering appealing alternatives to traditional petroleum-based options. These materials not only provide similar mechanical properties but also cater to the growing consumer demand for eco-friendly products.

Additionally, advancements in material formulations are enhancing the performance characteristics of injection molded parts. The development of high-performance thermoplastics, such as reinforced nylon and polycarbonate blends, allows for the creation of lighter, stronger components that can withstand more demanding applications. Coupled with innovations in additive manufacturing techniques, these materials enable designers to push the boundaries of what is possible in terms of part complexity and functionality. Emphasizing the ability to customize properties like heat resistance, flexibility, and durability, the materials of 2025 are setting the stage for a new era of injection molded products.

Materials Used in Injection Molding: Trends and Innovations for 2025

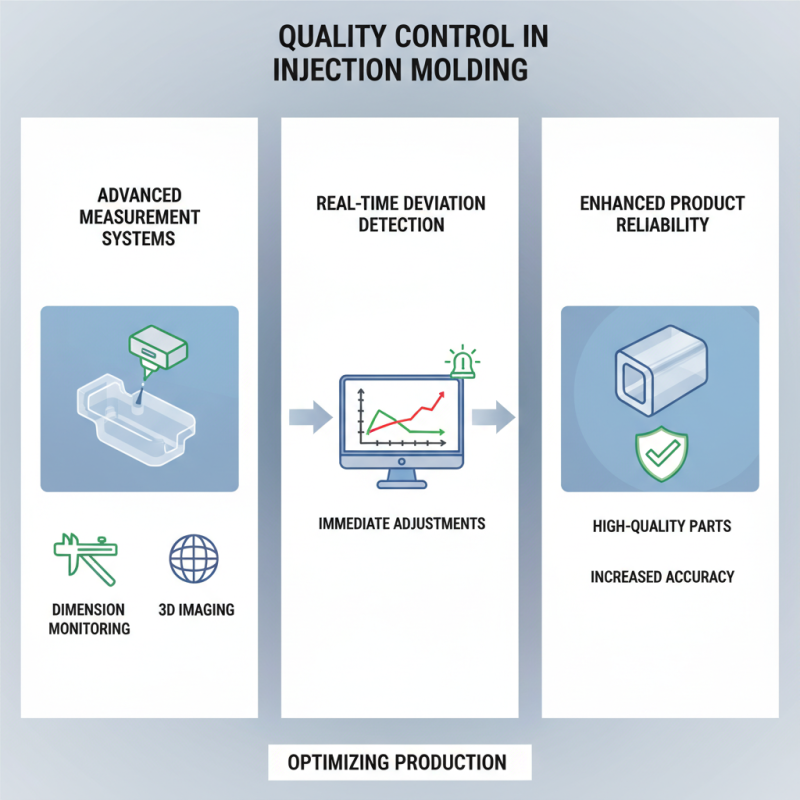

Quality Control Techniques for Improving Injection Molding Accuracy

Quality control is a critical aspect of the injection molding process, particularly when aiming to produce high-quality parts. One of the primary techniques to enhance accuracy is the implementation of advanced measurement systems. These systems utilize precision instruments to monitor dimensions and tolerances throughout the production cycle. By incorporating technologies such as laser scanning and 3D imaging, manufacturers can detect deviations from specifications in real-time, allowing for immediate adjustments that enhance the final product's reliability.

Another effective quality control technique involves the use of statistical process control (SPC). This method involves collecting data on production variables and using statistical analysis to identify trends and variations. By applying SPC, manufacturers can ensure that the injection molding process remains within predetermined limits. This proactive approach not only minimizes defects but also fosters continuous improvement initiatives, enabling teams to refine processes based on empirical evidence. As a result, the combination of advanced measurement tools and SPC can significantly boost the accuracy and quality of injection molded parts, paving the way for a more efficient manufacturing landscape in 2025.

Sustainability in Injection Molding: Eco-Friendly Practices for 2025

In 2025, sustainability will be at the forefront of injection molding practices. As industries seek to reduce their environmental impact, integrating eco-friendly methods in the injection molding process is crucial. Utilizing biodegradable materials, such as bioplastics, can significantly lessen reliance on fossil fuels and decrease carbon footprints. Additionally, recycling and reusing scrap materials will become standard practice, helping manufacturers minimize waste while supporting a circular economy.

Tips for achieving sustainability in injection molding include optimizing your production processes to reduce energy consumption. Consider investing in energy-efficient machines that consume less electricity without compromising output quality. Engaging in regular maintenance schedules will also ensure machines operate at peak efficiency, thereby minimizing energy waste. Another effective strategy is to implement a comprehensive waste management system that emphasizes recycling and material recovery during production.

Finally, collaborating with suppliers who prioritize sustainable practices can enhance the eco-friendliness of your products. Choosing partners that focus on ethically sourced materials and environmentally responsible practices ensures that your supply chain aligns with your sustainability goals. By adopting these eco-friendly practices in injection molding, manufacturers can lead the way in producing high-quality parts while protecting the planet.

Related Posts

-

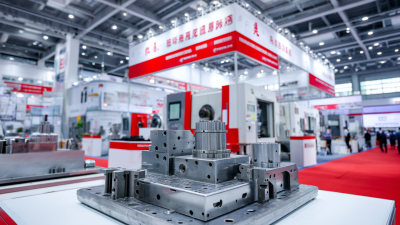

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

10 Essential Tips for Working with Injection Moldable Plastics

-

Top 5 Benefits of Using Plastic Molding in Modern Manufacturing Processes

-

What is Medical Injection Moulding and its Benefits in Healthcare

-

Why Is Injection Molding the Best Choice for Prototyping and Production

-

Why Injection Molding is Essential for Modern Manufacturing Success