10 Essential Tips for Effective Rapid Injection Molding Techniques?

In the realm of manufacturing, rapid injection molding has revolutionized the creation of plastic parts. Experts in the field, like Dr. Jane Smith, emphasize its significance: “Rapid injection molding is not just about speed. It's about efficiency and precision.” This technique allows for quick production cycles without sacrificing quality, attracting many manufacturers.

However, achieving excellence in rapid injection molding is not always straightforward. Complications can arise from material selection, mold design, or process parameters. Understanding these challenges is crucial. As the industry evolves, it becomes evident that continuous learning is a necessity. Mistakes can occur, and reflection on these experiences often leads to improvements.

In this dynamic landscape, mastering rapid injection molding techniques can define a company's success. The following tips aim to address common pitfalls and enhance production quality and efficiency. With careful attention, manufacturers can navigate this intricate process and harness the full potential of rapid injection molding.

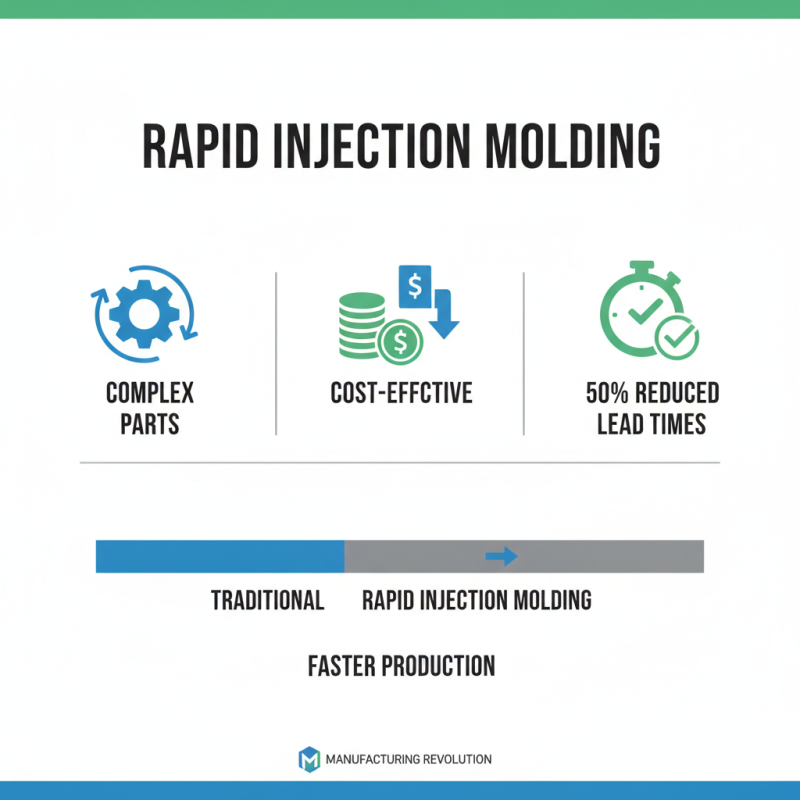

Understanding Rapid Injection Molding: Key Concepts and Advantages

Rapid injection molding is revolutionizing the manufacturing landscape. This method excels in producing complex parts quickly and cost-effectively. According to a recent industry report, rapid injection molding can reduce lead times by as much as 50%. This speed is crucial in markets that demand agility.

The advantages are substantial. Rapid injection molding allows engineers to create prototypes and production parts with precision. The typical cycle time is reduced to mere minutes, compared to hours in traditional molding. However, companies must remember to manage expectations. Not all designs are suitable for rapid techniques. Complex geometries may require careful design adjustments. It's vital to strike a balance between complexity and manufacturability.

Additionally, material selection plays a crucial role. High-quality thermoplastics can improve durability and performance. A report indicates that over 75% of manufacturers see a significant increase in product reliability when moving to this method. However, sourcing high-grade materials can sometimes present challenges. Companies should always assess their supply chain capabilities. The rapid injection molding process offers remarkable benefits, yet it is not without hurdles that demand continuous evaluation.

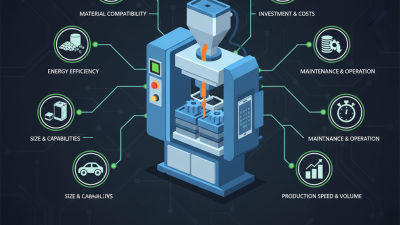

Essential Materials for Optimal Performance in Rapid Injection Molding

In rapid injection molding, the choice of materials is crucial. Selecting the right thermoplastics can make or break the production process. Commonly used materials like ABS and polypropylene are popular for their excellent balance of strength and flexibility. However, these may not always provide optimal results, depending on the product requirements. It's essential to consider specific project needs, like heat resistance or impact strength, when choosing materials.

Furthermore, not all materials perform equally well under rapid production conditions. Some may degrade or warp, leading to defective parts. It's important to test different materials under real-world conditions. Sometimes, using a more expensive yet high-performance polymer can save costs in the long run. This choice also enhances product durability and customer satisfaction.

The effectiveness of rapid injection molding often lies in experimenting. Understanding the unique properties of each material assists in fine-tuning the process. Observing real-time outcomes can lead to necessary adjustments. A successful molding operation requires careful consideration and sometimes trial and error in material selection. The right materials can elevate production quality, leading to better results over time.

Temperature Control Techniques for Enhanced Injection Molding Efficiency

Temperature control is crucial in injection molding. It affects the quality and efficiency of the final product. Maintaining the right temperature can prevent issues like warping or incomplete filling. A stable temperature also helps in reducing cycle times.

One effective tip is to use zone heating. This method ensures that different sections of the mold are at optimal temperatures. For instance, keep the injection zone and cooling channels at specific levels to aid flow and solidification. Adjusting the temperature based on the material used is vital. Not all plastics require the same heat settings.

Consider incorporating thermal imaging. This technique allows for real-time monitoring. Identifying hot spots can lead to quick adjustments. You might notice that some areas cool too quickly, impacting product quality. Have an analysis on hand to make regular adjustments. Don't overlook these tiny changes; they can make a significant difference. Experimenting with temperature settings can yield surprising results. Don't hesitate to test different scenarios. This approach can enhance efficiency and product integrity over time.

Achieving High Precision: Best Practices for Molding Parameters

Achieving high precision in rapid injection molding requires keen attention to molding parameters. Temperature control is crucial. The melt temperature should be optimized to prevent degradation and ensure uniformity. A consistent barrel temperature reduces the risk of material inconsistencies. If temperatures fluctuate, it can lead to defects. Keeping a close eye on these variables is essential for success.

Another key factor is injection speed. Fast injection rates can enhance the fill, but they also increase shear heating. This can negatively affect the accuracy of dimensions. Slow down when necessary and determine the right balance. Poor control of injection speed can result in flash or voids in the final product.

It's also vital to monitor cooling times. Overly short cooling periods can lead to warping. Conversely, excessive cooling can extend cycle times unnecessarily. Finding the optimal cooling time takes practice and observation. Reflecting on past molds helps identify what adjustments could yield better results. Continuous improvement is necessary in mastering these parameters.

Quality Assurance: Testing and Validation Methods in Injection Molding

Quality assurance in injection molding is crucial. It ensures products meet specific standards. A report by the Plastic Industry Association indicates that 30% of defects arise from inadequate testing methods. This highlights the need for effective validation protocols.

Testing and validation should begin at the design phase. Using simulations can identify potential issues early. The Use of finite element analysis (FEA) can predict material behavior under stress. This technology helps avoid costly errors. Moreover, physical testing, like tensile and impact tests, can verify material strength. A recent study showed that products tested at multiple stages have a 50% higher success rate.

However, even rigorous processes may not eliminate all defects. The risk of human error remains high during production. Many defects go unnoticed until they reach the consumer. Implementing a robust feedback loop can address this. Gathering data from end-users provides insights for improvement. Regular audits and process reviews should be a standard practice. This proactive approach can significantly reduce the rate of defective products.

10 Essential Tips for Effective Rapid Injection Molding Techniques

| Tip No. | Tip Description | Expected Outcome | Validation Method |

|---|---|---|---|

| 1 | Choose the right material for your application. | Improved product durability and performance. | Material testing and performance analysis. |

| 2 | Optimize mold design to enhance flow. | Reduced cycle time and better part quality. | Flow analysis simulations. |

| 3 | Implement precise temperature control. | Consistent part dimensions and properties. | Thermal imaging and temperature logging. |

| 4 | Use simulation software to predict outcomes. | Enhanced decision-making in the design phase. | Simulation validation against physical testing. |

| 5 | Regularly maintain and inspect molds. | Increased mold lifespan and reliability. | Systematic inspection and maintenance log review. |

| 6 | Utilize real-time monitoring systems. | Immediate identification of anomalies. | Data logging and statistical process control. |

| 7 | Train staff on best practices and safety. | Safer work environment and improved productivity. | Training program evaluation and feedback. |

| 8 | Conduct thorough pre-production testing. | Reduction in production errors and defects. | Prototype testing and evaluation reports. |

| 9 | Optimize cycle times without compromising quality. | Increased output and reduced costs. | Cycle time analysis and comparison. |

| 10 | Incorporate feedback for continuous improvement. | Long-term enhancements in production processes. | Feedback analysis and improvement workshops. |

Related Posts

-

10 Best Plastic Injection Molding Machines for Quality Production?

-

The Best 10 Tips for Optimizing Injection Tooling Efficiency

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development