10 Essential Tips for Working with Injection Moldable Plastics

Injection moldable plastics play a crucial role in modern manufacturing, enabling the production of complex and durable parts across various industries. According to a report by Markets and Markets, the global market for injection molded plastics is projected to reach $335 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.0% from 2021 to 2026. This growth highlights the increasing demand for efficient and cost-effective materials in industries such as automotive, consumer goods, and electronics.

As experts in the field note, understanding the intricacies of working with injection moldable plastics can significantly impact production efficiency and product quality. Dr. Emily Hart, a leading authority on polymer technology, emphasizes, "Mastering the fundamentals of injection moldable plastics is essential for any manufacturer looking to innovate and stay competitive in today's fast-paced market." With this in mind, implementing best practices when handling these materials becomes imperative for achieving optimal results and maintaining a competitive edge.

In this guide, we will explore ten essential tips that can help manufacturers successfully navigate the complexities of injection moldable plastics, ensuring quality outputs and enhanced operational efficiency. By focusing on proper selection, processing techniques, and design considerations, stakeholders can unlock the full potential of these versatile materials.

Understanding the Basics of Injection Moldable Plastics for Effective Design

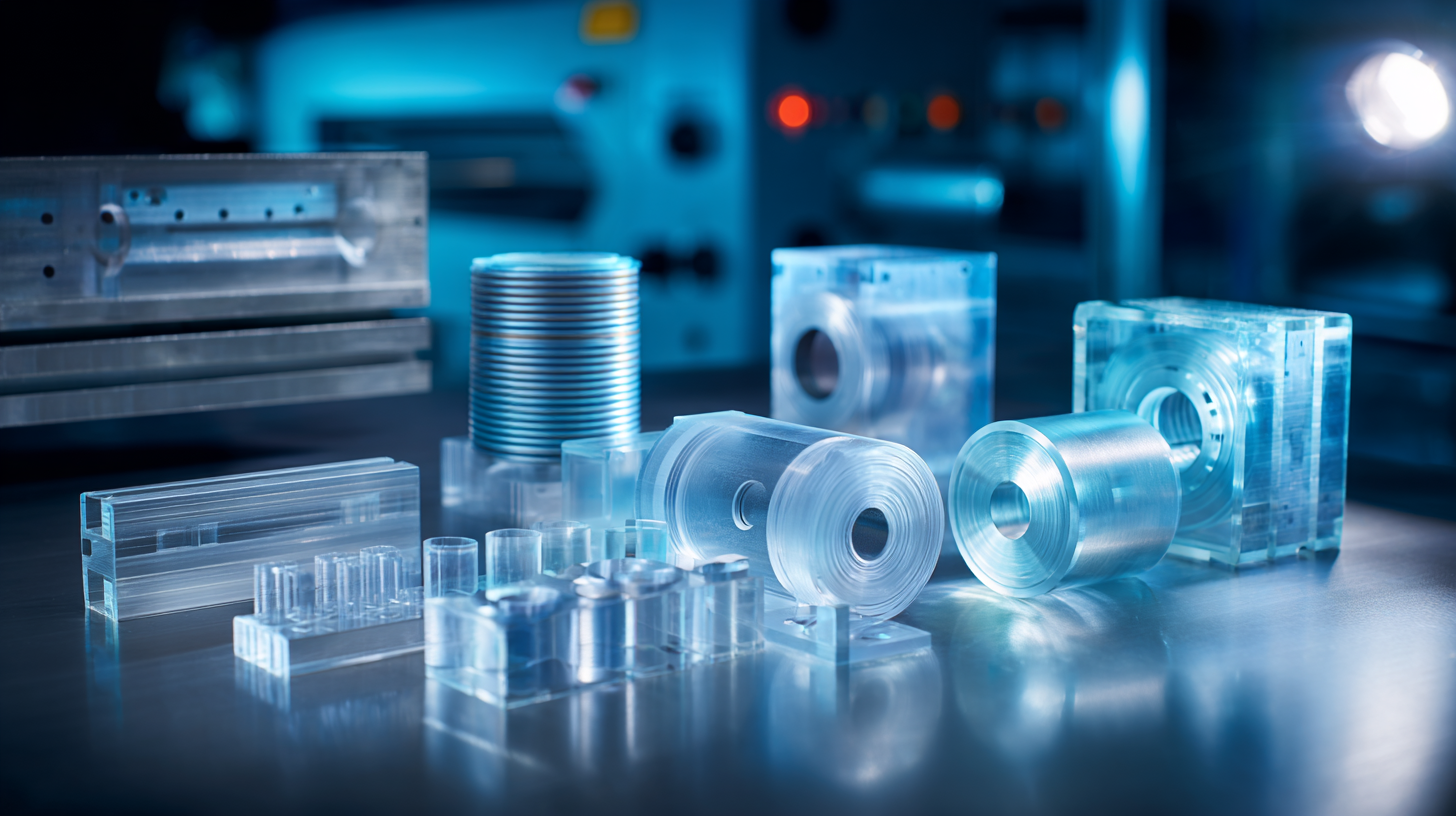

When working with injection moldable plastics, understanding the fundamental properties and processing techniques is crucial for effective design. The selection of materials impacts not only the physical attributes of the final product but also the efficiency of the manufacturing process. Familiarizing yourself with the basics of injection molding can streamline design efforts and minimize common errors.

One essential tip for designing with injection moldable plastics is to prioritize simplicity in part geometry. Avoid intricate shapes that complicate the molding process and increase the likelihood of defects. Additionally, ensure that appropriate venting is incorporated into the mold design. This is often overlooked, yet proper venting allows gases to escape during injection, preventing issues like burn marks and incomplete filling.

Another key consideration is validating the molding process. Proper validation ensures that the plastic parts meet the intended specifications and performance criteria. Each step, from material selection to mold design, plays a vital role in achieving successful outcomes. Regularly revisiting these foundational principles can lead to improved efficiency and product quality in injection molding endeavors.

Key Factors Influencing the Selection of Injection Moldable Plastics

When selecting injection moldable plastics, several key factors come into play that can significantly influence the choice of material. One of the primary considerations is the mechanical properties required for the finished product. According to a report by the Plastics Industry Association, up to 65% of parts produced via injection molding require materials that can withstand high tensile strength and impact resistance. Therefore, engineers often turn to high-performance plastics like ABS and polycarbonate, which offer exceptional durability and resilience.

Another crucial factor to consider is the thermal stability of the material, especially for applications exposed to varying temperature conditions. The same report highlights that nearly 30% of manufacturers encounter issues related to dimensional stability when using low-grade plastics under thermal stress. Selecting materials with a high Heat Distortion Temperature (HDT) can mitigate such risks. Additionally, processing characteristics, including melt flow index and cooling rates, are essential as they directly affect cycle times and ultimately production efficiency; for instance, materials like polypropylene are favored for their excellent flow properties in complex mold designs, enabling faster production cycles.

10 Essential Tips for Working with Injection Moldable Plastics

Common Challenges in Injection Molding and How to Overcome Them

Injection molding can present various challenges that may impact the efficiency and quality of the final product. One common issue is warping, which occurs when the molded part cools unevenly or when it is removed from the mold too soon. To mitigate this, it is crucial to maintain a consistent temperature in the mold and to ensure that the cooling system is properly designed and maintained. Additionally, implementing a controlled cooling cycle can help minimize the stresses on the part during the solidification process.

Another prevalent challenge in injection molding is short shots, where the mold is not completely filled with plastic. This often happens due to insufficient material flow or incorrect settings on the injection molding machine. To overcome this, processors should ensure that the machine is calibrated correctly, the material is of high quality, and the gating system is appropriately designed to facilitate better flow. Adjusting the injection speed and pressure can also contribute to achieving complete fills, thereby enhancing the overall production efficiency. Addressing these challenges is essential for achieving optimal results in injection moldable plastics.

Best Practices for Optimizing Injection Molding Processes

Optimizing injection molding processes is crucial for enhancing efficiency and product quality in the plastics industry. According to a 2022 report by the Plastics Industry Association, proper mold design and maintenance can reduce cycle times by up to 20%. Implementing advanced simulation software during the design phase allows engineers to predict flow patterns and make informed adjustments, ultimately improving material usage and reducing scrap rates.

Optimizing injection molding processes is crucial for enhancing efficiency and product quality in the plastics industry. According to a 2022 report by the Plastics Industry Association, proper mold design and maintenance can reduce cycle times by up to 20%. Implementing advanced simulation software during the design phase allows engineers to predict flow patterns and make informed adjustments, ultimately improving material usage and reducing scrap rates.

Another pivotal aspect of optimization is temperature control during the injection molding process. The American Injection Molding Institute emphasizes that maintaining consistent temperatures can decrease part defects by approximately 15%. Incorporating real-time monitoring systems for temperature and pressure not only enhances product integrity but also enables manufacturers to respond swiftly to variations, ensuring a seamless production flow. Adopting these best practices leads to significant cost savings and increased throughput, making it essential for companies striving to maintain competitive advantage in the injection molding market.

Sustainable Approaches in the Use of Injection Moldable Plastics

When it comes to working with injection moldable plastics, sustainability is a crucial factor that manufacturers and designers should prioritize. One of the primary approaches is to utilize biodegradable plastics, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA). These materials not only reduce the environmental impact of plastic waste but also provide viable alternatives for various applications. By choosing these sustainable options, companies can align their practices with eco-friendly standards and cater to the growing consumer demand for environmentally responsible products.

Another important aspect is the implementation of recycling and closed-loop systems in the injection molding process. Utilizing recycled plastics in the injection molding process can significantly cut down material waste and energy consumption. Moreover, designing products for disassembly allows for easy recycling at the end of their life cycle, ensuring that valuable materials can be recovered and reused. By adopting these sustainable approaches, businesses can contribute to a more circular economy while also enhancing their brand's reputation for environmental stewardship.

Related Posts

-

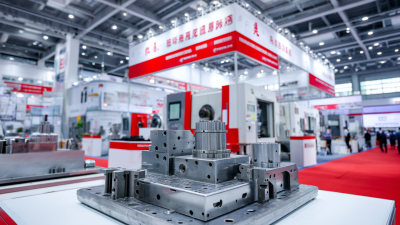

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development