Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

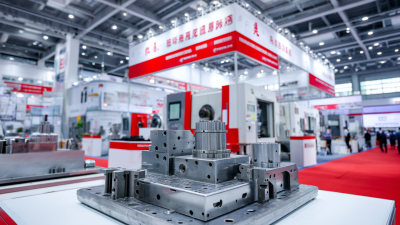

In 2023, the landscape of manufacturing continues to be reshaped by advancements in technology, particularly in the realm of injection molding machines. These machines are pivotal in the production of complex plastic components, serving diverse sectors from automotive to consumer goods. Recent industry reports indicate that the global injection molding machine market is expected to reach $14.78 billion by 2025, driven by the rising demand for lightweight and durable materials. Key innovations such as energy-efficient servo motors and enhanced automation are significantly improving efficiency and reducing cycle times, offering manufacturers a competitive edge.

As companies strive for sustainability, the integration of smart technologies enables real-time monitoring and analytics, streamlining operations and minimizing waste. Understanding these trends is crucial for stakeholders aiming to leverage the full potential of injection molding machines in an increasingly dynamic marketplace.

Key Innovations in Injection Molding Machines: A 2023 Perspective

The field of injection molding machines has undergone significant transformation in 2023, driven by several key innovations aimed at enhancing efficiency and sustainability. One of the most notable advancements is the integration of smart technology and IoT capabilities, allowing for real-time monitoring and predictive maintenance. This technology enables manufacturers to optimize machine performance, reduce downtime, and minimize waste. By utilizing data analytics, operators can make informed decisions that improve production flow and energy consumption.

Another crucial innovation is the development of advanced materials and eco-friendly polymers. These materials not only enhance the quality of molded products but also contribute to environmental sustainability. Innovations in machine design, such as faster clamping systems and precision injection techniques, further streamline the manufacturing process. As a result, companies are now able to increase production rates while maintaining higher quality standards. Collectively, these innovations are setting new benchmarks in the injection molding industry, paving the way for more efficient and sustainable production practices in 2023.

Integrating Smart Technology: How AI and IoT Enhance Molding Processes

The integration of smart technology into injection molding machines in 2023 marks a significant revolution in manufacturing efficiency. By employing artificial intelligence (AI) and the Internet of Things (IoT), manufacturers can now achieve unprecedented control and optimization over their molding processes.

AI algorithms analyze vast amounts of data in real-time, enabling predictive maintenance that minimizes downtime and enhances machine longevity. This proactive approach not only reduces costs but also ensures a seamless production flow.

AI algorithms analyze vast amounts of data in real-time, enabling predictive maintenance that minimizes downtime and enhances machine longevity. This proactive approach not only reduces costs but also ensures a seamless production flow.

Moreover, IoT devices facilitate a more connected environment, allowing for the monitoring of machine performance from remote locations. This connectivity enables manufacturers to gather insights on operational efficiency and identify potential bottlenecks before they escalate into significant issues. The result is an agile production system that can quickly adapt to changing demands. By harnessing the power of smart technologies, the injection molding industry is poised to enhance productivity, reduce waste, and improve overall product quality, setting new standards for excellence in 2023.

Energy Efficiency in Injection Molding: Measuring the Impact of Latest Systems

In 2023, the injection molding industry is witnessing a significant shift towards energy efficiency, largely influenced by advancements in machine technology. Recent data from the Plastics Industry Association indicates that modern injection molding machines can reduce energy consumption by up to 40% compared to their predecessors. This is largely due to innovations such as servo-electric drives and advanced hydraulic systems, which enhance performance while minimizing energy usage. These systems allow manufacturers to optimize production cycles, resulting in not only lower operational costs but also a reduced carbon footprint.

Tips: To maximize energy efficiency, manufacturers should consider regular maintenance of their machines. Ensuring that all parts are functioning optimally can prevent energy waste that occurs from overworked or malfunctioning components. Additionally, investing in machine upgrades can lead to significant savings in the long run.

Furthermore, employing real-time monitoring solutions enables operators to track energy usage and identify inefficiencies in the production process. According to a report by Allied Market Research, the adoption of smart technology in injection molding is projected to grow, bolstering both efficiency and sustainability efforts. This data highlights a trend where companies are not only improving their bottom line but also contributing to a more sustainable environment.

Tips: Implementing energy management systems can help in analyzing consumption patterns and making informed decisions to further enhance energy efficiency.

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

| Year | Innovation | Impact on Energy Efficiency (%) | Feature Description |

|---|---|---|---|

| 2021 | Hybrid Technology | 25% | Combines electric and hydraulic systems for better control and efficiency. |

| 2022 | Smart Monitoring Systems | 30% | Uses IoT technology to monitor energy consumption and optimize usage. |

| 2023 | Advanced Cooling Techniques | 20% | Improves cycle times and reduces energy loss during cooling phases. |

| 2023 | AI-Powered Optimization | 35% | Utilizes machine learning algorithms to optimize machine settings dynamically. |

The Role of Advanced Materials in Revolutionizing Molding Techniques

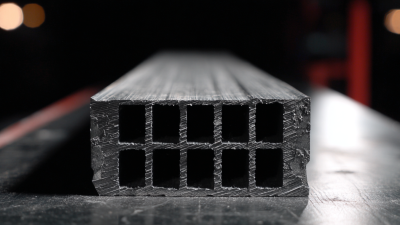

The evolution of injection molding machines in 2023 is significantly influenced by the integration of advanced materials, transforming traditional molding techniques. Recent industry reports highlight that approximately 60% of manufacturers are now adopting high-performance polymers and composites to meet the increasing demand for lightweight and durable products. These materials not only enhance the final product's strength but also ensure greater design flexibility, enabling the production of complex geometries previously deemed unfeasible.

Moreover, the incorporation of smart materials like thermoplastics and bio-based resins is revolutionizing the sustainability aspect of molding processes. According to a market analysis by Research and Markets, the global bio-based polymer market is expected to grow at a CAGR of 20% from 2021 to 2028, indicating a significant shift toward more environmentally friendly practices in the industry. This transition not only reduces waste but also aligns with regulatory trends focusing on sustainability and eco-friendliness.

Tip: When selecting materials for injection molding, consider the long-term performance and recyclability. Utilizing advanced materials can often offset initial costs due to their durability and efficiency in production.

Tip: Keep abreast of emerging material technologies and innovations to stay competitive. Adapting to new advancements not only improves product quality but can also optimize production costs in the long run.

Cost Reduction Strategies: Innovations Leading to Lower Production Expenses

In 2023, the landscape of injection molding machines is being dramatically reshaped by innovative cost reduction strategies that promise to enhance production efficiency. Companies are increasingly utilizing advanced technologies, including artificial intelligence, to streamline their operations. For instance, breakthroughs in generative AI have enabled firms to cut marketing content production costs by 30% to 50%. Such innovations not only reduce expenses but also allow for quicker turnaround times in manufacturing processes.

In addition to technological advancements, the injection molding industry is also responding to the growing pressure of high raw material costs. With commodities like copper and gold significantly impacting production costs, manufacturers are exploring alternative materials and processes to alleviate financial burdens. The emphasis on developing new techniques, such as the “direct deamination” strategy in pharmaceuticals, illustrates a broader trend within various sectors to innovate ways that substantially lower production expenses without compromising quality. As these cost-effectiveness methods proliferate, the injection molding machine industry is poised for significant transformation, driving both sustainability and efficiency in production.

Understanding the Evolution of Injection Molding Machines: Innovations Driving Efficiency in 2023

This chart illustrates the impact level of various key innovations driving efficiency in injection molding machines in 2023. Each innovation contributes significantly to reducing production costs and enhancing operational efficiency.

Related Posts

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing