Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

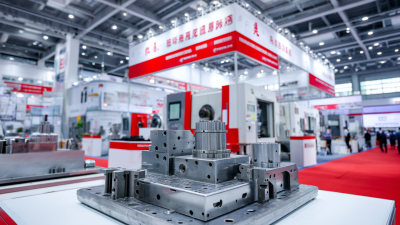

As the manufacturing landscape continues to evolve, understanding the future of injection molding materials becomes increasingly crucial for industries striving for innovation and efficiency. Injection molding, a widely used process for shaping plastics and other materials, demands a keen awareness of emerging trends and technological advancements. In this article, we will explore the key innovations in injection molding materials that are shaping the industry, including advancements in bioplastics, composites, and smart materials. By examining the latest research, market trends, and sustainability efforts, we aim to provide valuable insights for manufacturers and engineers looking to adapt and thrive in a competitive environment.

Embracing these developments not only enhances product performance but also contributes to a more sustainable future, making it essential for professionals to stay informed about the dynamic world of injection molding materials.

Emerging Materials in Injection Molding: Key Innovations to Watch

The landscape of injection molding is rapidly evolving, driven by advancements in materials technology. Key innovations are emerging that promise to enhance performance, sustainability, and versatility. For instance, bio-based plastics are gaining traction, with market reports indicating that the global market for bioplastics in injection molding is projected to reach $8.6 billion by 2025. As consumer demand for eco-friendly products rises, manufacturers are turning to sustainable materials that not only reduce environmental impact but also meet stringent regulatory standards.

Another area to watch is the development of high-performance thermoplastics. Materials such as polyether ether ketone (PEEK) and polyphenylene sulfide (PPS) are becoming increasingly popular for their exceptional thermal and chemical resistance properties. According to a recent industry analysis, the high-performance thermoplastics market is expected to grow at a CAGR of over 10% through 2030. This trend opens up new possibilities for applications in aerospace, automotive, and medical industries, where reliability is paramount.

Tips: When exploring new materials for injection molding, consider not only their performance characteristics but also the sustainability aspects. Conduct a life-cycle analysis to gauge the environmental impact of the materials you choose. Additionally, staying updated with industry reports will help you identify which innovative materials are gaining traction in the market, allowing your business to remain competitive.

Sustainability in Injection Molding: Eco-Friendly Material Alternatives

Sustainability has become a cornerstone of innovation in the injection molding industry, leading to the rise of eco-friendly material alternatives. According to a recent report by Research and Markets, the global biodegradable plastics market is projected to reach $20 billion by 2025, driven by increasing regulatory pressures and consumer demand for sustainable products. These biodegradable materials, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), not only reduce environmental impact but also offer comparable performance to traditional plastics, making them viable options for diverse applications.

Moreover, advancements in recycling technologies are enhancing the feasibility of using recycled materials in injection molding processes. A study from the Plastics Industry Association indicates that the recycling rate of plastic products rose to nearly 9% in the United States in 2022, creating a greater availability of recycled content for manufacturers. Companies are increasingly adopting practices such as using post-consumer recycled (PCR) plastics, which not only help in waste reduction but also align with the growing consumer preference for sustainable sourcing. As the industry embraces these innovations, the shift towards eco-friendly materials in injection molding is anticipated to significantly reshape production methodologies and promote environmental stewardship.

Smart Materials: The Role of IoT in Injection Molding Advancements

The integration of IoT technology into the injection molding industry is revolutionizing the production process by enhancing efficiency and enabling smart materials. IoT devices facilitate real-time monitoring and data collection, allowing manufacturers to optimize their operations. According to a recent report by Mordor Intelligence, the global smart materials market is projected to reach $150 billion by 2025, highlighting the growing emphasis on incorporating advanced materials in manufacturing processes. These innovations not only improve product quality but also reduce waste and energy consumption, aligning with industry sustainability goals.

Moreover, IoT-enabled smart materials are offering solutions that enhance the performance of injection molded products. For instance, materials that can adapt to environmental changes or user interaction create opportunities for more dynamic applications in various fields, from automotive to consumer goods. Research from MarketsandMarkets indicates that the demand for intelligent injection molding solutions is expected to grow at a CAGR of 12.5% over the next five years, underscoring the critical importance of staying ahead in this competitive landscape. As manufacturers increasingly adopt these technologies, the future of injection molding looks to be not only smarter but also more sustainable.

Cost-Effectiveness vs. Performance: Balancing Trends in Material Selection

The balance between cost-effectiveness and performance in material selection is increasingly critical in the injection molding industry as innovations emerge. With the growing demand for advanced materials, companies are exploring options that not only reduce costs but also enhance performance characteristics. For instance, the global PVC market is poised to grow significantly, indicating a trend towards material choices that offer both affordability and durability. This trend reflects the industry's shift toward sustainable practices while maintaining product integrity.

Additionally, as electric vehicles gain traction, the demand for high-performance materials in power electronics has surged. The innovations in materials such as tungsten-copper alloys, which are projected to see a steady compound annual growth rate, showcase the industry's eagerness to invest in new technologies that can deliver better efficiency and reliability. The emphasis on advanced materials like bioplastics and high-performance composites illustrates the ongoing efforts to find solutions that meet both performance standards and cost targets, underscoring a pivotal trend in the future of injection molding materials.

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

| Material Type | Cost per kg (USD) | Mechanical Properties | Thermal Stability (°C) | Sustainability Score (1-5) |

|---|---|---|---|---|

| Polypropylene (PP) | 1.20 | Tensile Strength: 30 MPa | 110 | 4 |

| Acrylonitrile Butadiene Styrene (ABS) | 2.00 | Tensile Strength: 40 MPa | 100 | 3 |

| Polyethylene Terephthalate (PET) | 1.80 | Tensile Strength: 50 MPa | 70 | 5 |

| Polycarbonate (PC) | 3.00 | Tensile Strength: 70 MPa | 130 | 2 |

| Nylon (PA) | 2.50 | Tensile Strength: 60 MPa | 90 | 3 |

Future-Proofing Injection Molding: Adapting to Market Demands with New Materials

As the injection molding industry continues to evolve, adapting to market demands becomes crucial for manufacturers. New materials are at the forefront of this transformation, offering enhanced properties, sustainability, and specificity for various applications. By investing in innovative materials, companies can not only improve product performance but also respond swiftly to consumer trends, ensuring they remain competitive in a rapidly changing landscape.

**Tips:** Consider conducting regular market research to identify emerging trends in materials science. This proactive approach allows you to stay ahead of competitors and align your production processes with market expectations. Collaborating with material suppliers can also provide insights into the latest advances that may benefit your operations.

Moreover, sustainability is becoming a non-negotiable factor in material selection. Manufacturers should explore bioplastics and recycled materials that not only meet functional requirements but also appeal to environmentally-conscious consumers. Implementing these materials can significantly enhance your brand’s reputation while contributing positively to the planet.

**Tips:** Evaluate your current material usage and explore alternatives that offer sustainability without compromising quality. Engaging with your supply chain partners can facilitate the transition to more sustainable practices, positioning your business as a leader in eco-friendly manufacturing solutions.

Understanding Material Innovations in Injection Molding (2023)

This bar chart illustrates the market demand for various innovative materials used in injection molding for 2023. As sustainability takes precedence in manufacturing, biodegradable and recycled plastics lead the demand, while high-performance polymers and composites are gaining traction for specialized applications.