Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

As the demand for advanced manufacturing continues to surge in Canada, the injection molding industry is poised for significant growth and transformation. According to a recent report by Mordor Intelligence, the Canadian injection molding market is projected to reach USD 5.6 billion by 2025, driven by a robust automotive sector and increasing applications in consumer goods and healthcare. Innovations in technology, such as automation and improved materials, are reshaping the landscape of injection molding Canada, enhancing efficiency and sustainability. Furthermore, the rise of Industry 4.0 is introducing data-driven practices that optimize production processes and reduce waste. This evolving environment not only reflects changing consumer demands but also highlights the critical role of collaboration between businesses and technology providers in driving forward the next generation of injection molding solutions. As we explore the future of this industry, it is essential to understand the key trends and innovations that will define its trajectory in the coming years.

Understanding the Basics of Injection Molding Technology in Canada

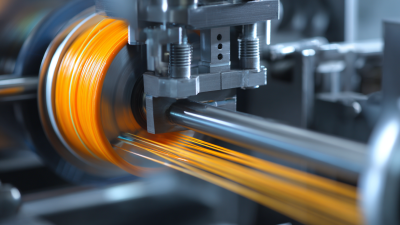

Injection molding technology is a critical aspect of Canada’s manufacturing landscape, providing versatile and efficient methods for producing plastic components. Understanding the basics of this technology involves recognizing the importance of key machine components and performance evaluations. As highlighted in recent discussions about machine evaluations, it's essential to conduct regular tests on injection molding machines to ensure optimal functionality. By assessing components such as the injection unit, clamping unit, and control systems, manufacturers can maintain the integrity and longevity of their equipment.

Injection molding technology is a critical aspect of Canada’s manufacturing landscape, providing versatile and efficient methods for producing plastic components. Understanding the basics of this technology involves recognizing the importance of key machine components and performance evaluations. As highlighted in recent discussions about machine evaluations, it's essential to conduct regular tests on injection molding machines to ensure optimal functionality. By assessing components such as the injection unit, clamping unit, and control systems, manufacturers can maintain the integrity and longevity of their equipment.

In the context of the latest industry developments, companies are increasingly focusing on energy efficiency and cutting-edge innovations. New special edition machines have been developed to provide greater energy savings, reflecting a trend towards sustainability in the manufacturing process. Additionally, advancements in product offerings, such as the introduction of twin-screw technologies, are expanding the capabilities of injection molding, enabling more intricate designs and faster production cycles. These trends not only enhance the efficiency of manufacturing processes but also position Canada as a competitive player in the global injection molding market.

Identifying Key Innovations Transforming Injection Molding Processes

The injection molding industry in Canada is undergoing significant transformation, driven by key innovations that promise to enhance efficiency and reduce costs. One of the most notable advancements is the integration of automation technologies. According to a report by Grand View Research, the global injection molding market is expected to reach USD 395.5 billion by 2027, with automation being a primary factor in this growth. Manufacturers are increasingly adopting robotic systems to streamline operations, ensuring precision while simultaneously improving cycle times.

Another critical innovation reshaping the industry is the adoption of advanced materials, including biodegradable plastics and lightweight composites. A study by Market Research Future indicates that the demand for sustainable materials is gaining momentum, with a projected compound annual growth rate (CAGR) of over 8% in the next five years. This shift not only meets the growing consumer demand for eco-friendly products but also allows manufacturers to comply with tighter regulations aimed at reducing environmental impact. By leveraging these innovations, the Canadian injection molding sector is poised to enhance product quality and operational efficiency, driving the industry towards a more sustainable future.

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

| Innovation | Description | Impact | Trend Adoption Rate (%) |

|---|---|---|---|

| Additive Manufacturing Integration | Combining traditional injection molding with 3D printing for rapid prototyping and reduced lead times. | Increases design flexibility and accelerates product development. | 45 |

| Biodegradable Materials | Use of eco-friendly polymers that reduce environmental impact. | Meets consumer demand for sustainable products and complies with regulatory standards. | 60 |

| Smart Factories | Implementation of IoT and AI to monitor and optimize production processes. | Enhances efficiency, reduces waste, and lowers operational costs. | 50 |

| Enhanced Cooling Systems | Advanced cooling techniques that improve cycle times and part quality. | Increases production speed and reduces defects, leading to better overall efficiency. | 55 |

| Automation and Robotics | Use of automated systems for handling, assembling, and quality control. | Reduces labor costs and enhances precision in manufacturing processes. | 65 |

Assessing the Impact of Sustainability on Canadian Injection Molding Practices

Sustainability has become a central theme in the evolution of injection molding practices in Canada, driven by both regulatory pressures and market demand for environmentally friendly products. Manufacturers are increasingly adopting sustainable materials, such as bio-based plastics and recycled compounds, to reduce their carbon footprint. This shift not only helps in conserving resources but also aligns with the growing consumer preference for eco-conscious products. As innovation in material science advances, more sustainable options are becoming viable, propelling the industry towards greener practices.

Moreover, injection molding companies are integrating energy-efficient technologies into their processes. This includes the use of advanced machinery that minimizes energy consumption and waste generation. Automation and smart manufacturing also play a crucial role in enhancing efficiency and reducing the overall environmental impact of production. By investing in sustainable practices, Canadian injection molding firms can not only comply with environmental regulations but also gain a competitive edge in a market increasingly influenced by sustainability criteria. This dual focus on eco-friendliness and innovation positions the injection molding industry in Canada for significant growth while addressing pressing environmental challenges.

Exploring Emerging Trends in Materials and Design for Injection Molding

The injection molding industry in Canada is experiencing a transformative phase driven by emerging trends in materials and design. With the growing emphasis on sustainability, manufacturers are increasingly adopting biodegradable and recycled polymers, which not only reduce environmental impact but also align with consumer preferences for eco-friendly products. Innovations in material science are leading to high-performance thermoplastics that offer superior strength, flexibility, and durability, making them suitable for a wide array of applications in automotive, consumer goods, and healthcare sectors.

The injection molding industry in Canada is experiencing a transformative phase driven by emerging trends in materials and design. With the growing emphasis on sustainability, manufacturers are increasingly adopting biodegradable and recycled polymers, which not only reduce environmental impact but also align with consumer preferences for eco-friendly products. Innovations in material science are leading to high-performance thermoplastics that offer superior strength, flexibility, and durability, making them suitable for a wide array of applications in automotive, consumer goods, and healthcare sectors.

In addition to advancements in materials, design innovations play a crucial role in shaping the future of injection molding. The integration of advanced computer-aided design (CAD) software and simulation tools allows engineers to optimize mold designs for efficiency and precision. This results in reduced cycle times and improved product quality. Furthermore, the trend towards personalized manufacturing is being facilitated by techniques such as 3D printing and additive manufacturing, enabling the production of custom molds and components with unparalleled accuracy. As these trends converge, they are not just enhancing the capabilities of the injection molding process, but also setting the stage for a more dynamic and responsive manufacturing landscape in Canada.

Evaluating the Role of Automation and Digitalization in the Industry’s Future

The future of injection molding in Canada is set to be significantly influenced by automation and digitalization. According to a recent report by MarketsandMarkets, the global injection molding market is projected to reach USD 379.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.7% from 2020 to 2025. A substantial portion of this growth is attributed to advancements in automation technologies, which enhance efficiency, reduce production costs, and minimize human error. Canadian manufacturers are increasingly investing in robotic systems and automated machinery, allowing for faster cycle times and improved productivity.

Moreover, the integration of digital technologies such as the Internet of Things (IoT) and artificial intelligence (AI) is reshaping the injection molding landscape. The 2022 Deloitte report highlights that 66% of Canadian manufacturers are already implementing or planning to adopt Industry 4.0 technologies. These advancements enable real-time monitoring of production processes, predictive maintenance, and enhanced quality control. By leveraging big data analytics, companies can gain deeper insights into operational efficiency and customer preferences, allowing them to innovate and adapt more swiftly in a competitive market.

Related Posts

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development