Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

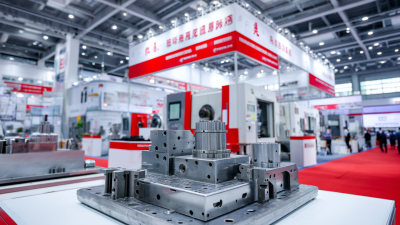

The landscape of injection molding materials is witnessing transformative innovations and trends that are poised to redefine the industry in the coming years. According to a recent market report by Mordor Intelligence, the global injection molding market is expected to reach USD 300 billion by 2027, driven by advancements in material technology and sustainability initiatives.

Notably, the use of bio-based plastics and recycled materials is on the rise, reflecting a growing demand for environmentally friendly solutions. Furthermore, the integration of smart materials and additive manufacturing techniques is revolutionizing traditional injection molding processes, enabling manufacturers to enhance product design and reduce waste. As we delve into the future of injection molding materials, it is essential to explore these pivotal developments that will not only improve efficiency but also contribute to a greener manufacturing landscape.

Notably, the use of bio-based plastics and recycled materials is on the rise, reflecting a growing demand for environmentally friendly solutions. Furthermore, the integration of smart materials and additive manufacturing techniques is revolutionizing traditional injection molding processes, enabling manufacturers to enhance product design and reduce waste. As we delve into the future of injection molding materials, it is essential to explore these pivotal developments that will not only improve efficiency but also contribute to a greener manufacturing landscape.

Innovative Materials Revolutionizing Injection Molding Processes

The injection molding industry is currently experiencing a remarkable transformation, driven by innovative materials that enhance the efficiency and sustainability of manufacturing processes. According to a report by Allied Market Research, the global injection molding market is projected to reach $450 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.8% from 2019 to 2026. This growth is largely attributable to advancements in polymer technology, such as the rise of bio-based and recycled materials, which are gaining traction in response to increasing environmental concerns.

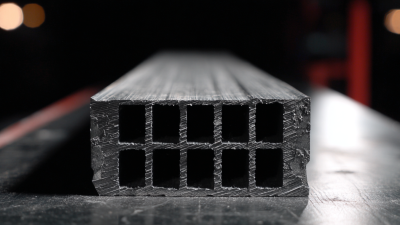

One notable trend is the development of high-performance thermoplastics, such as polyether ether ketone (PEEK) and polyamide (PA), which offer superior strength and thermal stability. These materials are setting new benchmarks in applications ranging from automotive to aerospace, where durability and weight reduction are paramount. Furthermore, innovations in additive manufacturing are inspiring the creation of hybrid materials that combine the benefits of multiple polymers, enhancing design flexibility and opening up new avenues for custom applications. A report by Grand View Research indicates that the biodegradable plastics segment is expected to see significant growth, with a forecasted CAGR of over 15% by 2027, showcasing the industry’s shift towards sustainable alternatives in injection molding.

Biodegradable Plastics: Paving the Way for Sustainable Manufacturing

Biodegradable plastics are emerging as a crucial innovation in the injection molding materials landscape, particularly in response to increasing environmental concerns. According to a report from Allied Market Research, the global biodegradable plastics market is projected to reach $6.94 billion by 2025, growing at a CAGR of 16.4%. This shift is driven by the demand for sustainable manufacturing processes that minimize environmental impact while maintaining product performance.

One of the most significant trends in the industry is the development of biopolymers derived from renewable resources. Materials such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are gaining traction for their lower carbon footprints compared to traditional petroleum-based plastics. For instance, the European Bioplastics Association estimates that the production capacity of biodegradable plastics is expected to increase significantly, potentially doubling by 2025. The integration of these materials in injection molding not only aligns with global sustainability goals but also offers manufacturers an opportunity to meet regulatory requirements and consumer preferences for eco-friendly products.

Smart Polymers: Enhancing Performance and Functionality in Products

The emergence of smart polymers is revolutionizing the injection molding industry by enhancing both performance and functionality of products. These advanced materials are engineered to respond dynamically to environmental stimuli such as temperature, pH levels, or light. As a result, they can change their shape, stiffness, or even color, offering unprecedented versatility and adaptability in end-use applications. Industries ranging from medical devices to consumer electronics are beginning to harness the capabilities of smart polymers, leading to more innovative, efficient, and user-friendly products.

Moreover, the integration of smart polymers in injection molding processes has significant implications for product design and manufacturing efficiency. By utilizing these materials, manufacturers can produce components that not only meet stringent performance criteria but also reduce waste and energy consumption during production. The ability of smart polymers to perform in challenging conditions and self-heal when damaged further extends their appeal. As research advances and technological developments continue to emerge, the potential for smart polymers to reshape the landscape of various industries is substantial, paving the way for smarter, more responsive products in the future.

3D Printing Integration: Bridging Traditional Molding with Additive Techniques

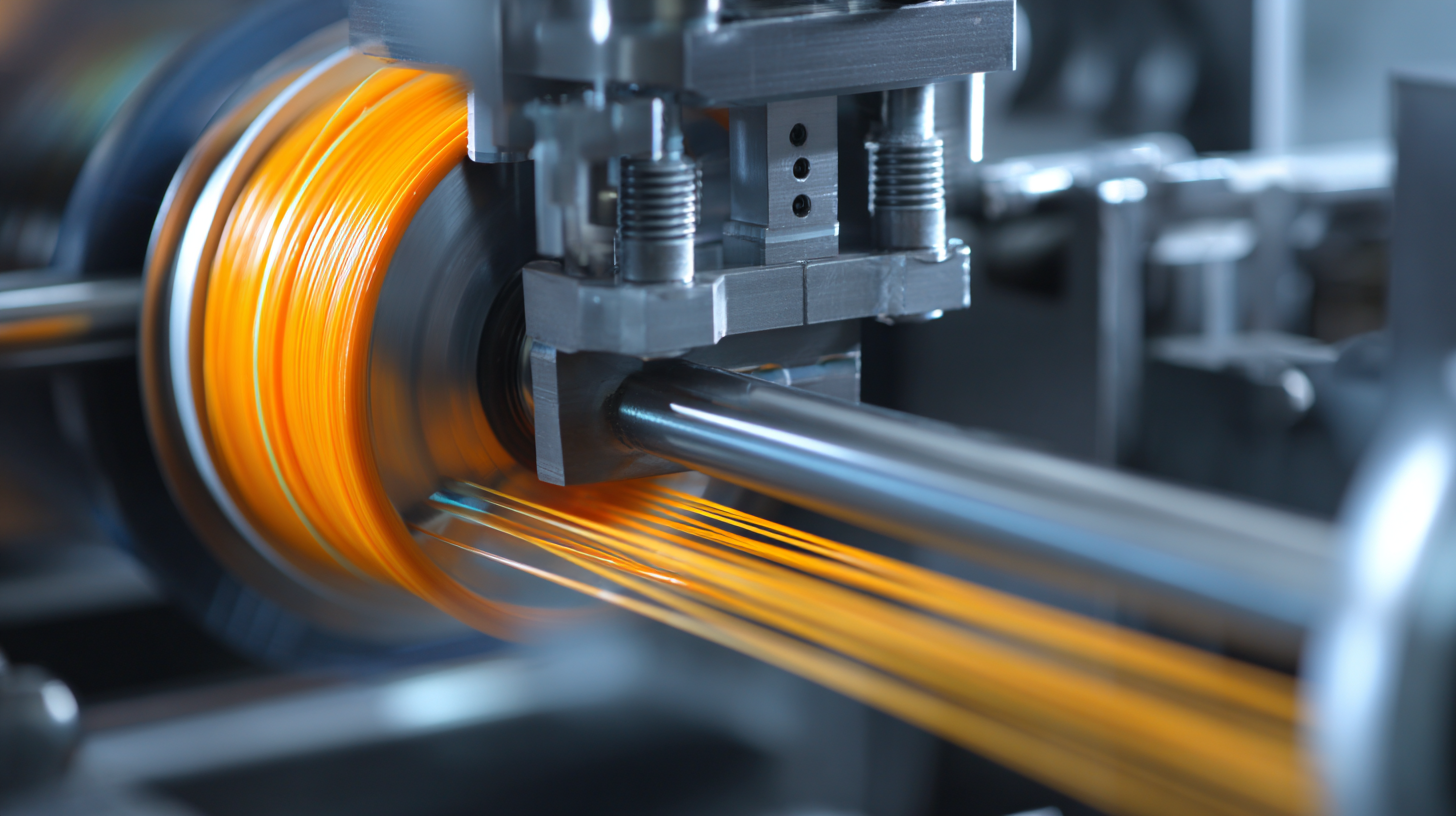

The integration of 3D printing with traditional injection molding techniques represents a transformative trend in the manufacturing industry. As companies seek to enhance efficiency and reduce production costs, the fusion of additive manufacturing and conventional molding processes allows for innovative solutions. 3D printing enables the rapid prototyping of molds, significantly shortening lead times and facilitating design modifications that were previously time-consuming and expensive. This method not only accelerates the design-to-production timeline but also fosters creativity and customization in product development.

Furthermore, this synergy opens up new avenues for utilizing advanced materials that were not feasible with traditional molding alone. For instance, engineers can explore complex geometries and lightweight structures that enhance performance without compromising strength. The ability to employ a diverse range of materials in conjunction with 3D printing allows manufacturers to adapt to market demands swiftly. As these technologies continue to evolve, the collaboration between injection molding and additive manufacturing will redefine production processes, paving the way for more sustainable practices and reduced material waste in the industry.

Exploring the Future of Injection Molding Materials: Innovations and Trends

Advanced Recycling Technologies: Transforming Waste into Valuable Resources

The landscape of injection molding materials is undergoing a significant transformation, driven largely by advancements in recycling technologies. As industries strive to adopt more sustainable practices, the ability to convert waste into valuable resources has become paramount.

Innovative processes, such as chemical recycling and advanced sorting techniques, are now enabling the recovery of polymers from post-consumer waste, making it possible to reintroduce these materials into the manufacturing cycle. This not only reduces the environmental footprint but also lowers costs associated with raw material procurement.

Innovative processes, such as chemical recycling and advanced sorting techniques, are now enabling the recovery of polymers from post-consumer waste, making it possible to reintroduce these materials into the manufacturing cycle. This not only reduces the environmental footprint but also lowers costs associated with raw material procurement.

Tips: When selecting injection molding materials, consider the recyclability of the materials. Opt for those that can be easily processed and remolded, as this will enhance your sustainability efforts. Additionally, stay informed about the latest recycling technologies; they can provide opportunities to incorporate reclaimed materials into your production processes.

Moreover, collaboration between manufacturers and recycling companies is essential in driving this trend forward. By pooling expertise and resources, these partnerships can facilitate the development of new materials that are not only sustainable but also maintain high performance standards. As these innovations take hold, they promise to reshape the future of the injection molding industry, paving the way for more eco-friendly production practices and a circular economy.

Related Posts

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends