Exploring the Future of Rubber Injection Molding: Innovations and Applications in 2024

The rubber injection molding industry is on the brink of transformative advancements as we venture into 2024. This innovative manufacturing process, which allows for precise and efficient production of rubber components, is anticipated to grow significantly. According to a report by MarketsandMarkets, the global rubber injection molding market is projected to reach $20.1 billion by 2026, with a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth is fueled by the increasing demand for lightweight and durable materials across various industries, including automotive, aerospace, and consumer goods.

As we explore the future of rubber injection molding, several cutting-edge technologies and applications are emerging. For instance, advancements in automation and Industry 4.0 are enabling manufacturers to enhance production efficiency and reduce waste. Furthermore, the integration of advanced materials such as thermoplastic elastomers (TPEs) is expanding the versatility of rubber injection molding, making it suitable for a broader range of applications. These innovations not only optimize operational workflows but also address sustainability concerns by promoting the use of recyclable materials.

In conclusion, the future of rubber injection molding is poised for remarkable developments, driven by technological advancements and evolving market demands. By leveraging these innovations, businesses in the rubber manufacturing sector can position themselves at the forefront of industry trends, ensuring competitive advantage and growth in the coming years.

Innovative Materials Transforming Rubber Injection Molding in 2024

In 2024, the landscape of rubber injection molding is set to be transformed by innovative materials that enhance both functionality and application potential. The introduction of advanced materials, such as biocompatible and electro-conductive liquid silicone rubber, is pivotal for the development of modern healthcare devices.

These innovations not only ensure safety for medical applications but also facilitate the integration of electronic components, leading to smarter and more efficient health monitoring solutions.

The injection molding market itself continues to expand, with projections indicating significant growth in the coming years. By 2033, the market is anticipated to reach USD 580.44 billion, reflecting a 4.74% CAGR. This growth is driven by the rising demand for high-performance rubber components across various sectors, including automotive and consumer goods. Additionally, the recent developments showcased at industry events highlight the ongoing commitment to sustainability and innovation within the sector, ensuring that the future of rubber injection molding remains bright and impactful.

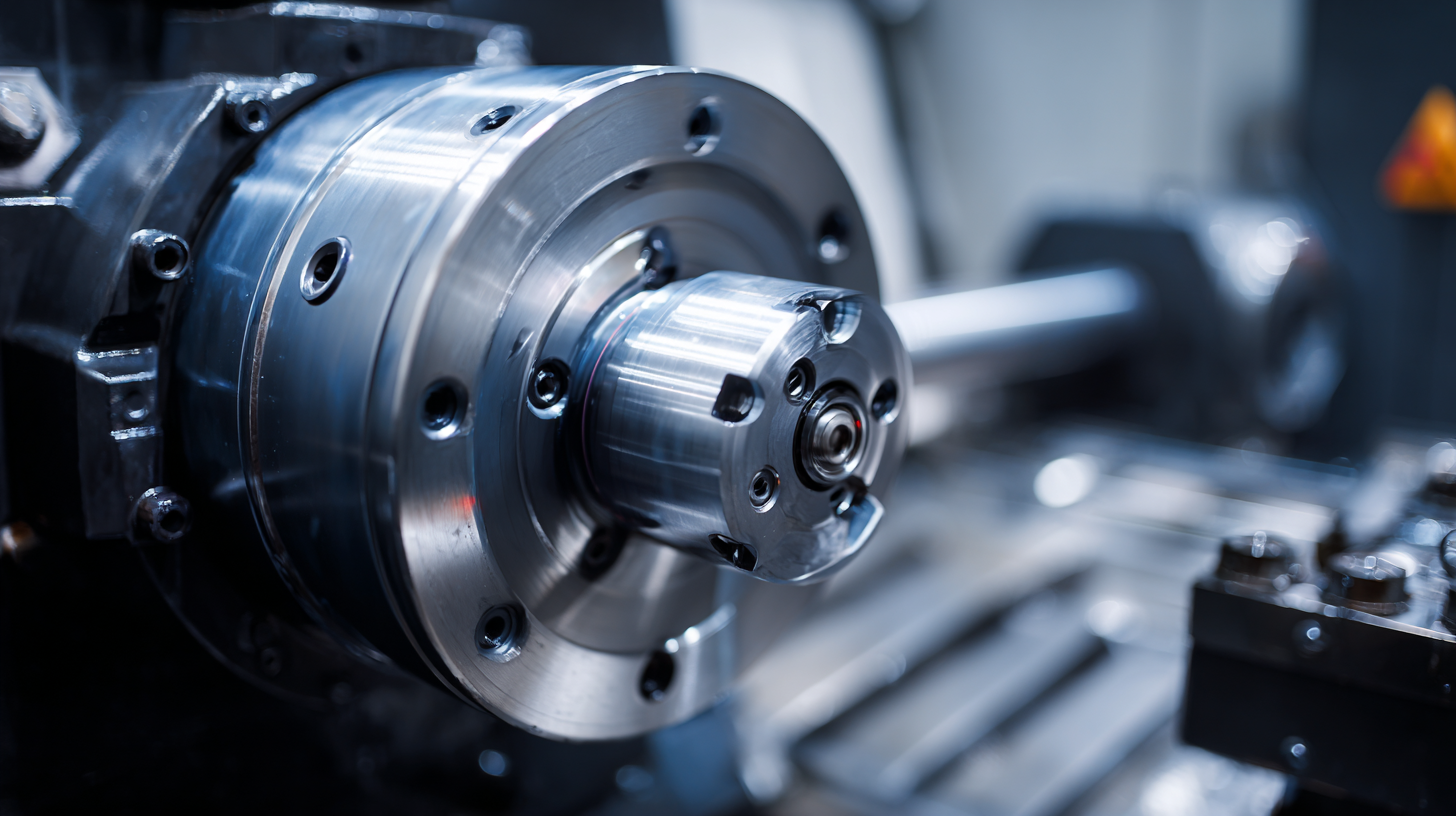

Key Technological Advancements Shaping the Future of Rubber Injection Molding

The rubber injection molding industry is poised for significant growth, driven by technological advancements that enhance efficiency and product quality. With the injection molding market projected to grow from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, innovations in machine automation and material science are crucial. Key advancements include the integration of smart technologies like IoT, which allows for real-time monitoring and predictive maintenance, thus minimizing downtime and optimizing production processes.

In the medical sector, experts highlight how advancements in rubber injection molding are vital. Technologies such as high-precision molding and biocompatible materials are steering the evolution of medical devices. As discussed in a recent industry dialogue, adopting advanced molding techniques can significantly impact design flexibility and product reliability, catering to the stringent demands of the healthcare market.

Tip: When considering rubber injection molding solutions, it's essential to evaluate the latest technologies that not only improve efficiency but also ensure compliance with regulatory standards, especially in sensitive sectors like healthcare. Staying updated on market trends and forecast reports can provide insights into the best practices for adopting these innovations effectively.

Sustainable Practices and Their Impact on Rubber Injection Molding Applications

In 2024, the rubber injection molding industry is set to witness substantial transformation, primarily driven by innovations focused on sustainability. The global healthcare rubber sales market is projected to reach a value of $900 million by 2024, with a compound annual growth rate (CAGR) of 4.8% through 2033. This growth is largely fueled by the demand for medical-grade materials, particularly liquid silicone rubber (LSR), which meets stringent safety and quality standards. The emphasis on using eco-friendly materials aligns with broader trends in manufacturing, making sustainable practices not just an ethical imperative but a competitive advantage.

Moreover, the global rubber injection molding machine market is expected to grow significantly, reflecting a wider market dynamic. The estimated market size in 2019 was approximately $15.39 billion, with projections indicating that it will reach around $25.39 billion by 2032, translating to a CAGR of 3.9%. This growth hints at increasing investments in technologies that enhance process efficiency while also prioritizing lower environmental impact. By integrating sustainable practices, manufacturers can not only meet regulatory requirements but also appeal to a growing consumer base that values sustainability, paving the way for innovative applications in various sectors.

Innovations and Applications in Rubber Injection Molding: Sustainability Impact (2024)

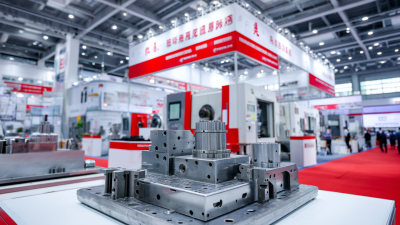

Emerging Market Trends Influencing Rubber Injection Molding in Diverse Industries

The rubber injection molding industry is undergoing significant transformations, driven by emerging market trends in various sectors. As industries increasingly seek to customize their products, the demand for innovative solutions is on the rise, particularly in regions like China and India. The injection molding market is expected to grow substantially, reaching USD 382.53 billion in 2025 and potentially hitting USD 580.44 billion by 2033, indicating a robust 4.74% CAGR. This surge is attributed to the rapid adoption of personalized products, exemplified by the increasing demand for customized 3D PVC rubber patches.

In India, the market for injection molding machines is projected to experience a commendable growth rate of 8.0% CAGR from 2025 to 2035, with the industry's value reaching USD 830.9 million. This growth is spurred by advancements in technology and manufacturing processes, allowing for greater efficiency and cost-effectiveness. As businesses leverage these innovations to meet consumer demands for tailored products, the rubber injection molding landscape is poised for dynamic evolution in 2024 and beyond, impacting diverse industries significantly.

Exploring the Future of Rubber Injection Molding: Innovations and Applications in 2024 - Emerging Market Trends Influencing Rubber Injection Molding in Diverse Industries

| Application Area | Innovation Trend | Market Growth (%) | Key Technologies | Sustainability Focus |

|---|---|---|---|---|

| Automotive | Lightweight Materials | 8.5% | 3D Printing, Recycled Rubber | High |

| Medical Devices | Customization for Precision | 10% | Bio-compatible Materials | Medium |

| Consumer Electronics | Integration with Smart Tech | 12% | Smart Materials, Sensors | Low |

| Construction | Durability Enhancements | 7.2% | High-performance Elastomers | High |

| Aerospace | Advanced Composite Use | 9% | Thermoplastic Elastomers | Medium |

Future Challenges and Opportunities in Rubber Injection Molding Processes

The rubber injection molding industry is poised for significant transformation as it faces various challenges and opportunities in the coming years. One of the most notable trends is the application of digital technologies, particularly machine learning, which is expected to revolutionize polymer research and enhance efficiency in molding processes. As companies strive to adopt sustainable practices, low-pressure injection molding emerges as a promising innovation that not only reduces material waste but also lowers energy consumption—making it an attractive option for environmentally-conscious manufacturers.

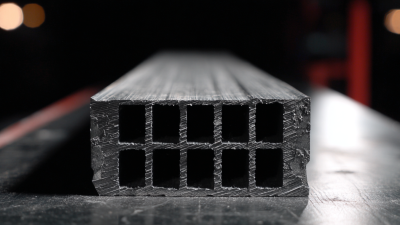

Additionally, the expansion of markets, particularly in regions like India, indicates a robust growth trajectory for injection molding machines driven by increased demand across diverse sectors. This growth is accompanied by advancements in material science, such as the incorporation of natural fibers to enhance the mechanical properties of rubber composites. These developments not only present opportunities for new product innovations but also challenge traditional manufacturing approaches to adapt and integrate sustainable practices into their operations.

Related Posts

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Innovative Plastic Profiles Shaping the Future of Construction and Design with 30 Percent Increased Durability

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025