Understanding the Injection Molding Process for Sustainable Product Development

The injection molding process is a pivotal technique in the manufacturing landscape, particularly as industries pivot towards sustainable product development. According to a report by Allied Market Research, the global injection molding market is projected to reach $410 billion by 2027, driven by the increasing demand for lightweight and durable materials. This process, characterized by its efficiency in producing high-precision parts, significantly reduces waste compared to traditional manufacturing methods.

Moreover, as companies increasingly commit to sustainable practices, innovations within the injection molding process—such as the use of biodegradable plastics and energy-efficient machinery—are becoming paramount. By harnessing these advancements, manufacturers not only enhance their productivity but also contribute positively to environmental conservation. Understanding the nuances of the injection molding process is thus essential for businesses striving to align with eco-friendly initiatives while maintaining competitive advantage in the marketplace.

Moreover, as companies increasingly commit to sustainable practices, innovations within the injection molding process—such as the use of biodegradable plastics and energy-efficient machinery—are becoming paramount. By harnessing these advancements, manufacturers not only enhance their productivity but also contribute positively to environmental conservation. Understanding the nuances of the injection molding process is thus essential for businesses striving to align with eco-friendly initiatives while maintaining competitive advantage in the marketplace.

Exploring the Basics of Injection Molding for Eco-Friendly Products

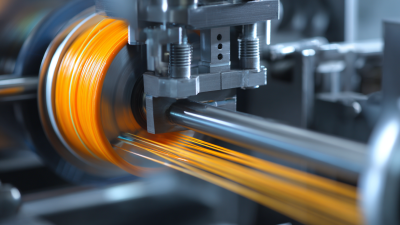

Injection molding is a widely utilized manufacturing process known for its efficiency and versatility, particularly in producing eco-friendly products. This technique involves injecting molten materials, typically plastics, into a mold to create precise shapes. Understanding the basics of injection molding is crucial for designers and manufacturers aiming to develop sustainable products that minimize waste and energy consumption.

Injection molding is a widely utilized manufacturing process known for its efficiency and versatility, particularly in producing eco-friendly products. This technique involves injecting molten materials, typically plastics, into a mold to create precise shapes. Understanding the basics of injection molding is crucial for designers and manufacturers aiming to develop sustainable products that minimize waste and energy consumption.

Tips: When selecting materials for injection molding, consider using recycled plastics or bio-based alternatives. These materials not only reduce environmental impact but also meet the growing consumer demand for sustainability. Additionally, optimizing the design of the molds can significantly decrease material usage and enhance production efficiency, leading to a lower carbon footprint.

Furthermore, the injection molding process allows for innovative design solutions that can incorporate features like lightweight structuring and multi-material components. Utilizing this flexibility can lead to the development of products that are not only eco-friendly but also durable and functional. By embracing these principles in product development, businesses can play a pivotal role in promoting sustainability in manufacturing practices.

Evaluating Material Choices for Sustainable Injection Molding

Sustainable product development increasingly hinges on the material choices made during the injection molding process. With growing awareness of environmental impact, manufacturers seek to incorporate eco-friendly materials into their production lines. This involves evaluating options such as polymer matrix composites, specifically focusing on materials like polyethylene (PE) and polypropylene (PP), which are widely used due to their favorable properties and recyclability.

Sustainable product development increasingly hinges on the material choices made during the injection molding process. With growing awareness of environmental impact, manufacturers seek to incorporate eco-friendly materials into their production lines. This involves evaluating options such as polymer matrix composites, specifically focusing on materials like polyethylene (PE) and polypropylene (PP), which are widely used due to their favorable properties and recyclability.

The type of application—whether it be through injection molding, blow molding, or profile extrusion—also plays a crucial role in material selection. For instance, using PE in injection molding not only provides excellent flexibility and toughness but also supports sustainability initiatives by being easily recycled. Similarly, PP offers a balance of performance and environmental benefits, making it another prime candidate for sustainable manufacturing practices. By prioritizing these materials, companies can effectively reduce their carbon footprint while meeting consumer demand for greener products.

Optimizing the Injection Molding Process for Energy Efficiency

The injection molding process, a cornerstone of modern manufacturing, can significantly benefit from optimization strategies aimed at increasing energy efficiency. According to a report by the American Society of Mechanical Engineers (ASME), energy consumption in injection molding operations can account for up to 70% of operational costs. By targeting energy-intensive phases of the process, manufacturers can implement techniques such as advanced heating systems and real-time monitoring to reduce their environmental footprint while simultaneously cutting costs.

One effective approach is the use of energy-efficient machines that incorporate servo motors instead of traditional hydraulic systems. Research indicates that servo-driven injection molding machines can reduce energy consumption by up to 50% compared to conventional machines (Plastics Technology, 2020). Additionally, optimizing cycle times and reducing material waste through improved mold design not only enhances productivity but also contributes to sustainable practices. By embracing these strategies, manufacturers can align with growing industry standards that emphasize sustainability, potentially attracting eco-conscious clients and securing a competitive edge in the market.

Energy Efficiency in Injection Molding Process

This chart illustrates the energy consumption (in kWh) during different stages of the injection molding process. The aim is to highlight the potential areas for energy optimization to support sustainable product development.

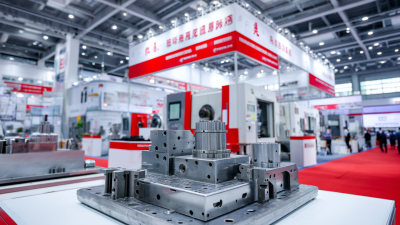

Design Strategies to Enhance Sustainability in Molding Products

Incorporating sustainable design strategies into the injection molding process is crucial for reducing environmental impact while meeting consumer demands. One effective approach is to utilize biodegradable and recycled materials, which can help minimize waste and resource depletion. By selecting polymers that can decompose or are made from post-consumer waste, manufacturers not only contribute to a circular economy but also enhance the appeal of their products to eco-conscious consumers.

Another essential strategy involves optimizing the design of molded products to reduce material usage and energy consumption during production. Techniques such as using advanced CAD software for simulation and testing can lead to lightweight designs that require less raw material without compromising functionality. Furthermore, integrating modular designs allows for easier repairs and upgrades, extending the product's lifecycle. Overall, these design strategies not only enhance the sustainability of molded products but also offer competitive advantages in an increasingly environmentally-focused market.

Understanding the Injection Molding Process for Sustainable Product Development

| Design Strategy | Materials Used | Sustainability Impact | Energy Efficiency |

|---|---|---|---|

| Use of Recycled Materials | Post-consumer recycled plastics | Reduces landfill waste and carbon footprint | Lower energy consumption in material processing |

| Design for Disassembly | Modular components | Facilitates recycling and reuse of components | Optimizes energy use in end-of-life processing |

| Incorporation of Bioplastics | PLA, PHA | Reduces reliance on fossil fuels | Varies based on source of bioplastic |

| Use of Energy Efficient Machines | Low energy hydraulic presses | Reduces operational energy costs | Up to 30% less energy consumption |

| Eco-friendly Mold Design | Aluminum molds | Longer lifespan and less material usage | Improved thermal dynamics for energy savings |

Assessing the Impact of Injection Molding on the Circular Economy

The injection molding process plays a pivotal role in the advancement of a circular economy by enabling the efficient production of sustainable products. By utilizing thermoplastics and bioplastics, manufacturers can create items designed for longevity and recyclability. This approach not only reduces waste but also emphasizes the need for materials that can be reprocessed at the end of their life cycle, thus minimizing the impact on the environment.

Furthermore, the integration of sustainable practices within the injection molding industry can significantly lower the carbon footprint associated with product development. Utilizing recycled materials as feedstock not only conserves resources but also reduces energy consumption during production. Additionally, advancements in technology have allowed for more precise molding techniques, reducing excess material use and improving overall efficiency. By aligning injection molding processes with circular economy principles, companies can contribute to a more sustainable future while meeting growing consumer demand for eco-friendly products.

Related Posts

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023