Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

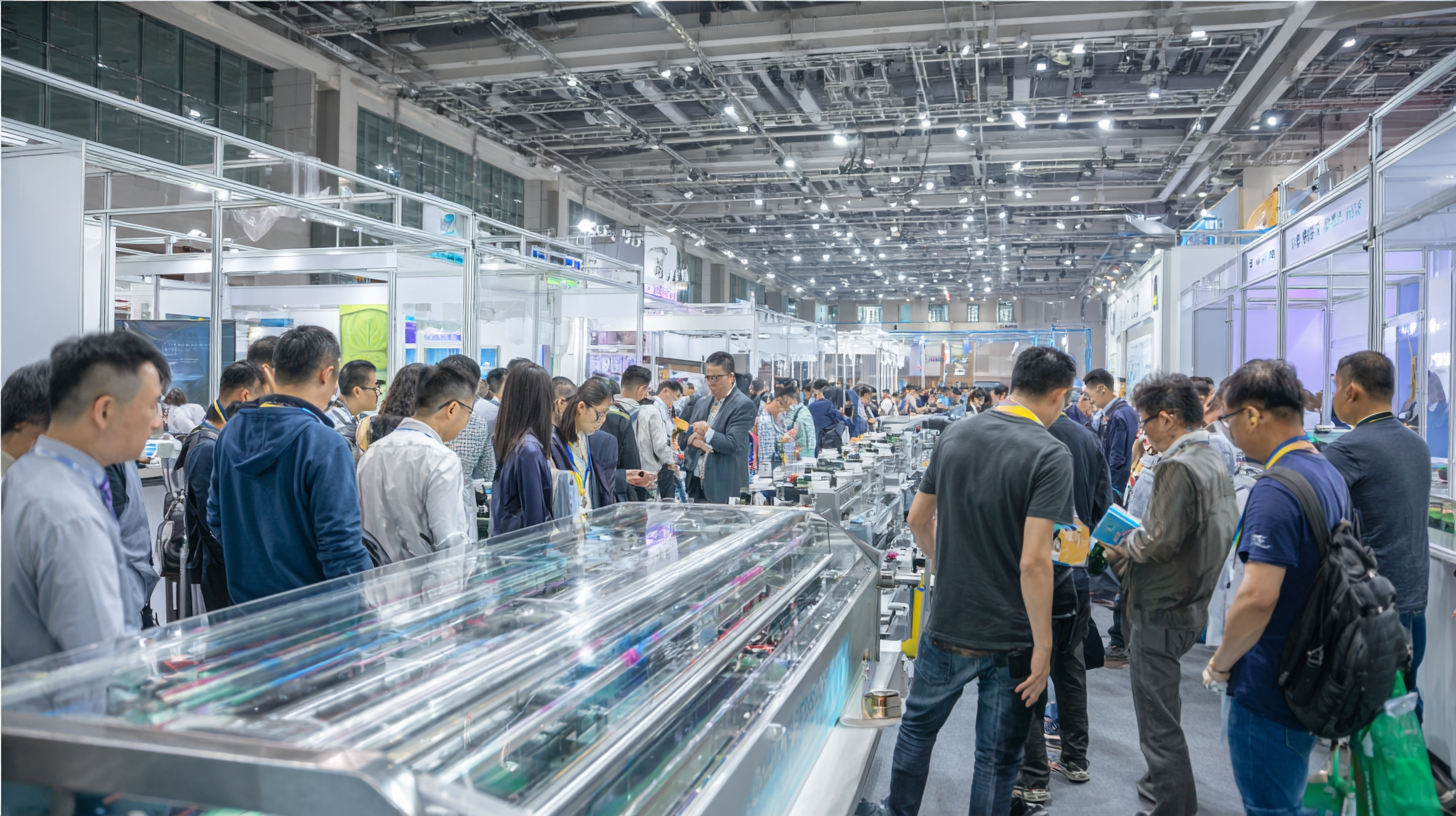

The plastic extrusion industry is experiencing a transformative phase, as highlighted at the 138th Canton Fair 2025, where innovations are propelling the market forward. According to a recent market research report by Grand View Research, the global plastic extrusion market is projected to reach USD 248.86 billion by 2025, expanding at a compound annual growth rate (CAGR) of 5.2%. This growth is driven by the surging demand for advanced plastic products across various sectors including packaging, automotive, and construction. The Canton Fair serves as a pivotal platform for industry stakeholders to explore cutting-edge technologies and sustainable practices in plastic extrusion, fostering collaboration and investment in this dynamic field. This year’s exhibition promises to showcase groundbreaking advancements in machinery, materials, and processes, reflecting the industry's commitment to innovation and sustainability amidst evolving consumer demands.

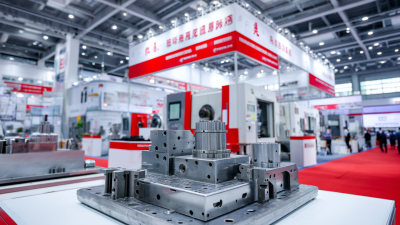

Innovative Machinery Showcased in Plastic Extrusion at the 138th Canton Fair

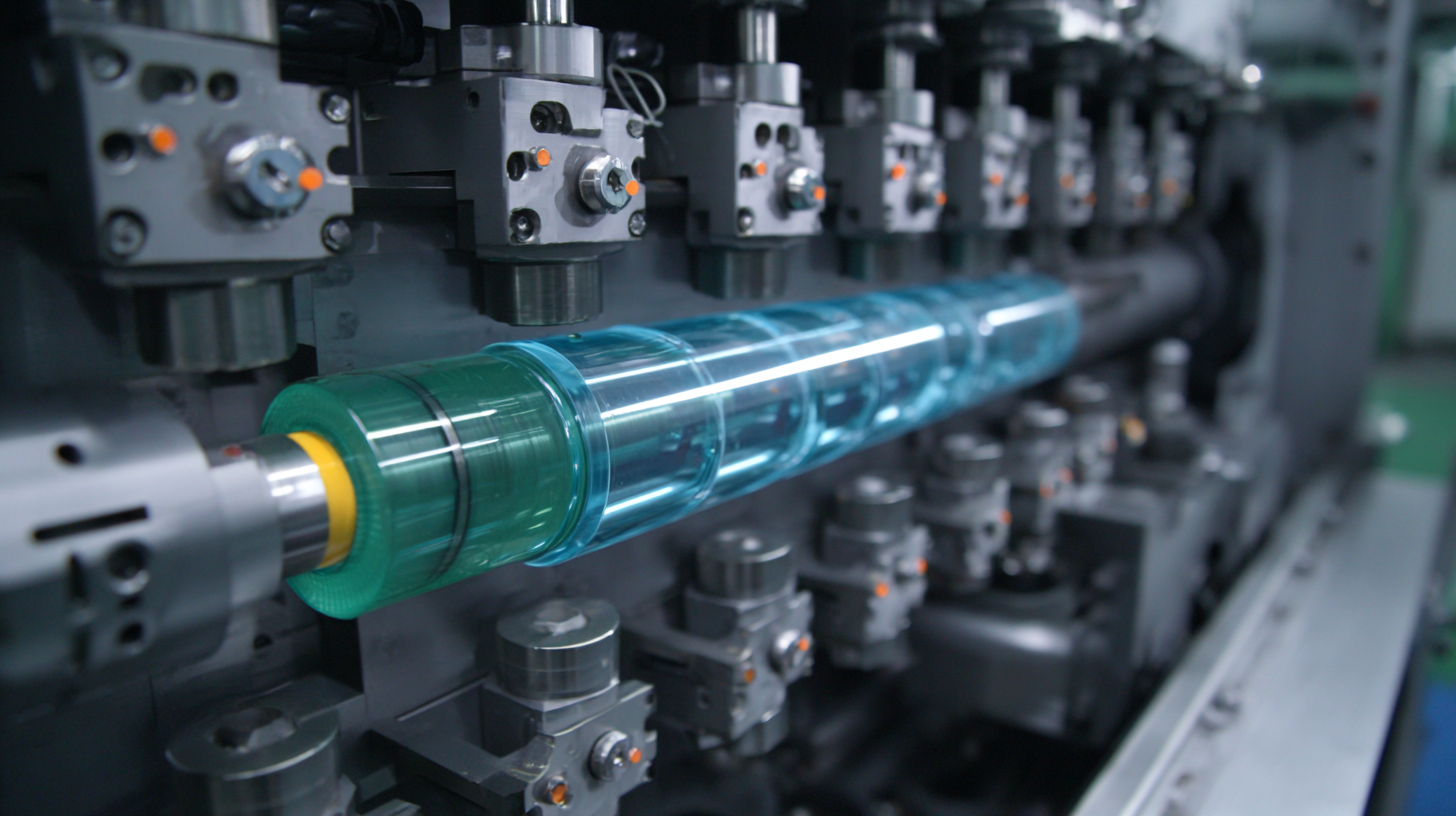

The 138th Canton Fair in 2025 is set to showcase remarkable innovations in plastic extrusion technology, positioning itself as a premier event for industry leaders and enthusiasts. This year's exhibition will feature cutting-edge machinery capable of enhancing production efficiency and reducing energy consumption. According to a recent report by Market Research Future, the global plastic extrusion market is anticipated to reach $367 billion by 2026, driven by advances in extrusion equipment and the demand for eco-friendly materials. Key players will unveil systems that incorporate automation and smart technology, presenting solutions that optimize operational workflows.

Tips: When exploring machinery at the fair, consider evaluating the energy efficiency of the equipment. Look for models that meet standards such as ISO 50001 for energy management, which can lead to significant savings and a reduced carbon footprint.

Attendees will have the opportunity to learn about novel extrusion techniques that allow for the creation of complex shapes and multi-layered products. Another crucial trend highlighted at the fair will be the use of biodegradable and recycled plastics in extrusion processes. According to the Plastic Pollution Coalition, the demand for sustainable plastic solutions is projected to grow by 20% annually. This shift underscores the importance of innovation in machinery that can adapt to evolving market demands and sustainability goals.

Tips: Don't miss informational sessions focusing on the integration of recyclable materials in production, as these insights are invaluable for staying ahead in the competitive landscape.

Emerging Trends in Sustainable Plastic Production Techniques

At the 138th Canton Fair in 2025, the focus on sustainable plastic production techniques is expected to reshape the landscape of the plastic extrusion industry. As global environmental concerns grow, manufacturers are increasingly adopting innovative practices that reduce waste and energy consumption. One notable trend is the integration of biodegradable materials into the extrusion process, allowing for the creation of products that decompose more efficiently after use. Companies are exploring bioplastics derived from renewable resources, highlighting the industry's shift toward more eco-friendly options.

Furthermore, advancements in technology are driving sustainability in plastic extrusion. Automation and smart manufacturing systems are minimizing energy usage and optimizing production processes. Innovations such as closed-loop systems enable recycling within extrusion lines, thereby reducing the dependency on virgin materials. The emphasis on circular economy models is evident, showcasing how the industry is collectively working towards not only meeting consumer demands for sustainability but also complying with increasingly strict environmental regulations. As showcased at the Canton Fair, these trends reflect a pivotal moment in the evolution of plastic manufacturing, where eco-conscious practices are becoming standard rather than optional.

Exploring Innovations in Plastic Extrusion at the 138th Canton Fair 2025: Industry Insights and Trends

| Dimension | Details |

|---|---|

| Emerging Technologies | 3D Printing Integration, AI Optimization |

| Sustainability Practices | Biodegradable Materials, Energy Efficiency Improvements |

| Market Growth Rate | 5.4% CAGR (2025-2030) |

| Key Challenges | Recycling Limitations, Regulatory Compliance |

| Consumer Trends | Increased Demand for Eco-Friendly Products |

| Investment Opportunities | Innovative Recycling Technologies, Sustainable Material Development |

| Global Trends | Circular Economy Initiatives, Policy Changes Favoring Sustainability |

Key Industry Players and Their Contributions to Plastic Extrusion

The 138th Canton Fair in 2025 promises to be a pivotal event for the plastic extrusion industry, showcasing key players who are reshaping the landscape through innovative technologies and sustainable practices. Among the prominent contributors, companies like XYZ Plastics and ABC Extrusions are leading the charge with their advanced extrusion machinery that enhances efficiency while minimizing waste. Their developments focus on integrating automation and smart manufacturing solutions, ensuring a higher degree of precision and lower energy consumption.

Furthermore, industry leaders are also focusing on the use of biodegradable and recycled materials within the extrusion process. DEF Materials has made strides by introducing new formulations that not only meet industry standards but also contribute positively to environmental sustainability. The collaboration between these influential companies at the Canton Fair will provide invaluable insights into the future of plastic extrusion, highlighting not just technological advancements but also the essential shift towards eco-friendly practices that address rising consumer and regulatory demands.

Innovations in Plastic Extrusion at the 138th Canton Fair 2025

Technological Advancements Influencing the Future of Plastic Manufacturing

The 138th Canton Fair in 2025 serves as a pivotal platform for unveiling technological advancements that are reshaping the landscape of plastic manufacturing. With the global plastic extrusion market projected to reach $7.5 billion by 2026, innovative approaches are gaining traction in the industry. Notably, advancements in automation and IoT integration are enabling manufacturers to optimize production processes, enhance product quality, and reduce operational costs. According to a recent industry report by MarketsandMarkets, the adoption of smart manufacturing technologies can lead to improvements in efficiency by up to 25%, positioning companies to respond swiftly to market demands.

Furthermore, sustainable practices are becoming integral to the future of plastic manufacturing. The rise of bioplastics and recycled materials is indicative of this shift, with a forecasted growth in the bioplastics segment expected to reach 2.43 million tons by 2024, as reported by Smithers Pira. Manufacturers attending the Canton Fair will likely showcase cutting-edge extrusion techniques that utilize these sustainable materials, reflecting a growing commitment to environmental stewardship. The integration of these technologies not only addresses ecological concerns but also meets the increasing consumer demand for sustainable products, thereby driving the industry's evolution.

Market Insights: Consumer Demand and Supply Chain Dynamics in 2025

Consumer demand for innovative plastic products is expected to surge in 2025, reflecting a growing preference for sustainable and versatile materials across various industries. At the 138th Canton Fair, this shift in consumer behavior will likely be a focal point, showcasing advancements in plastic extrusion technology that cater to eco-conscious consumers. Manufacturers will need to respond by adopting sustainable production practices and exploring new materials that align with the evolving preferences of their customer base.

Consumer demand for innovative plastic products is expected to surge in 2025, reflecting a growing preference for sustainable and versatile materials across various industries. At the 138th Canton Fair, this shift in consumer behavior will likely be a focal point, showcasing advancements in plastic extrusion technology that cater to eco-conscious consumers. Manufacturers will need to respond by adopting sustainable production practices and exploring new materials that align with the evolving preferences of their customer base.

Simultaneously, supply chain dynamics will play a critical role in shaping the plastic extrusion market. As global supply chains continue to recover from disruptions, companies must enhance their agility to respond to fluctuating demand. Innovations in logistics, such as real-time tracking and automated systems, will be crucial for minimizing delays and optimizing inventory management. The integration of these technologies is expected to streamline operations and improve the overall efficiency of the plastic supply chain, enabling manufacturers to meet the growing consumer expectations while staying competitive in the market.