2026 How to Master Injection Molding Techniques for Efficient Production?

Injection molding is a critical process in modern manufacturing. According to the Plastics Industry Association, this method accounts for over 30% of plastic products made globally. The efficiency of injection molding significantly influences production quality and costs. Many manufacturers overlook the importance of mastering their techniques. This often leads to high scrap rates and wasted materials.

Inefficient injection molding can result in defects and decreased output. A study by the American Society of Mechanical Engineers noted that up to 25% of production time is lost due to improper settings. Understanding how to optimize these settings is vital for improving productivity. Yet, many professionals still rely on outdated methods without reflecting on their impact.

In an industry constantly evolving with technology, staying updated on best practices is essential. Companies that invest in training and technology often outperform competitors. However, this requires commitment and openness to change. Increasing efficiency in injection molding is not just about machinery; it’s about people and processes too.

Understanding the Basics of Injection Molding in Manufacturing Processes

Injection molding is a crucial process in manufacturing. It allows for the efficient production of plastic parts, ranging from small components to large housings. Understanding the basics of this method can enhance productivity in various industries. At its core, injection molding involves melting plastic pellets and injecting them into a mold. This creates a solid object once cooled.

Tips: Always consider the material. Different plastics have unique melting points and cooling times. Testing various materials can lead to better choices for specific applications.

The success of injection molding relies on precision. Key factors include mold design, temperatures, and pressure settings. It is easy to overlook these details. A minor error in any variable can cause defects. Observing the cooling time is also critical. Too fast or too slow can affect the final product's strength.

Tips: Regular maintenance of equipment can prevent costlier downtime. Keep molds clean and checked to ensure consistent quality. Learning from failed runs can also provide insight, leading to improved techniques.

Key Materials Used in Injection Molding: Properties and Performance

Injection molding is a critical method in manufacturing. Understanding key materials used in this process is essential for efficiency. Thermoplastics dominate the market, constituting over 70% of materials. Polypropylene (PP) is particularly notable for its high versatility. It offers excellent fatigue resistance and is lightweight. Commonly used in automotive and consumer goods, PP shows great processing ease, which can reduce cycle times.

Another significant material is acrylonitrile butadiene styrene (ABS). This polymer is known for its toughness and impact resistance. ABS’s performance in various temperatures makes it suitable for many applications. Industry reports indicate that ABS has gained momentum, especially in electronics and toys. However, it can be challenging to process, requiring operators to maintain optimal conditions to avoid defects.

Additives play a vital role too. They can enhance properties like UV resistance or flame retardancy. However, choosing the wrong additive may lead to compromised performance. The market for injection molding materials is evolving. Analysts expect a 5% annual growth rate by 2027. This growth indicates the importance of material selection to meet changing demands. Failure to adapt can result in increased waste and production costs.

Optimal Machine Settings: Temperature, Pressure, and Speed for Efficiency

Mastering injection molding techniques requires a keen understanding of optimal machine settings. Key parameters such as temperature, pressure, and speed play a critical role in production efficiency. According to recent industry reports, a slight adjustment of temperature can affect cycle time by up to 30%. Maintaining a consistent melt temperature ensures quality and consistency in the final product. However, finding the precise temperature isn't straightforward. Overheating materials can create defects, highlighting the need for continuous monitoring.

Pressure settings also demand attention. Optimal injection pressure typically varies between 600 to 1,200 psi, depending on the material. Too much pressure can lead to warping, while too little may cause incomplete filling. Manufacturers must experiment within this range to find a sweet spot for their specific applications. A recent study revealed that improper pressure settings could reduce production output by nearly 20%. This discrepancy can result in significant financial losses if left unchecked.

Speed of injection is another crucial factor. A fast injection speed might improve cycle time, yet it can lead to quality issues. Balancing speed with quality requires careful analysis. Many factories still struggle with this balance, often yielding products that do not meet quality standards. Continuous refinement and testing of these parameters are vital for mastering injection molding. In this evolving industry, precision becomes a hallmark of success.

Optimal Machine Settings for Injection Molding Efficiency

This chart illustrates the optimal machine settings for injection molding. The blue bars represent the optimal settings for injection molding, while the red bars show typical settings. Adjusting the temperature, pressure, and speed according to these optimal values can enhance production efficiency.

Quality Control Measures in Injection Molding: Industry Standards and Metrics

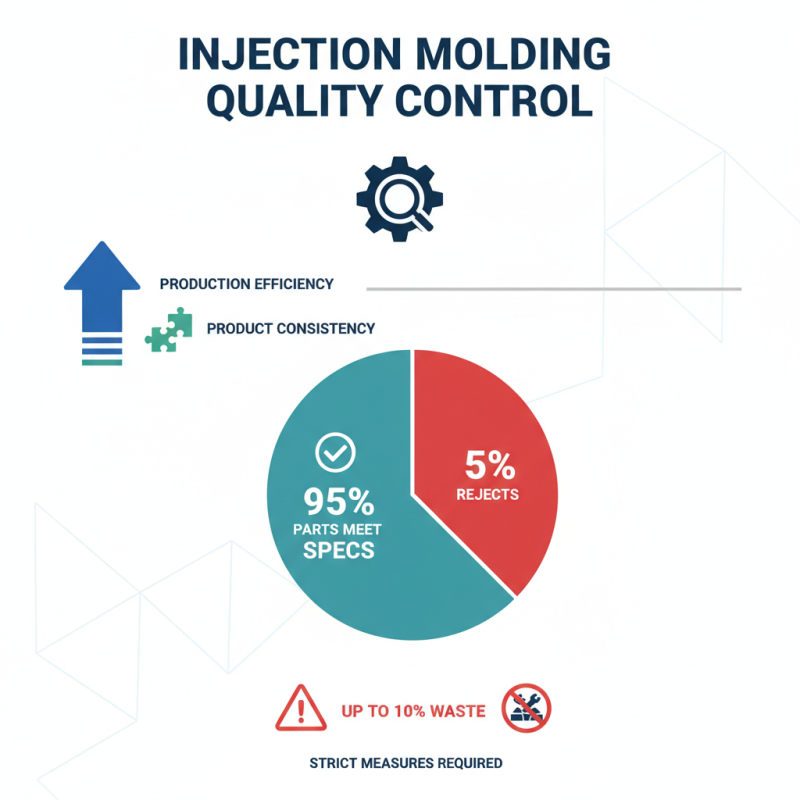

Quality control in injection molding is crucial. It directly impacts production efficiency and product consistency. The industry standard mandates that 95% of parts must meet dimensional specifications. Reports indicate that improper quality control can lead to a waste rate of up to 10%. This highlights the need for stringent measures.

Metrics are vital in quality assurance. Commonly used metrics include Cycle Time, Defect Rate, and First Pass Yield. Cycle Time should ideally be under 30 seconds per part. Yet, many factories report average times exceeding this. Defect Rates should stay below 2%. Still, some manufacturers face 5% or higher due to machine inconsistencies.

Training staff on quality control is often overlooked. Continuous education programs can improve awareness of standards. However, manufacturers sometimes fail to invest in this area. It's common to see employees unfamiliar with the latest practices. Regular audits and updates can bridge this knowledge gap. Investing in equipment is also essential. Accurate machinery can reduce errors, yet many industries operate outdated models. This creates a cycle of inefficiency that is hard to break.

Emerging Technologies in Injection Molding: Automation and Innovations

Injection molding is evolving rapidly. Automation is becoming a key player in this field. Robots are now handling complex tasks like material loading and part removal. This shift enhances efficiency and reduces human error.

Tips: Invest in training for your team. They need to understand these new technologies well. A skilled workforce can troubleshoot issues quickly. Additionally, simplify workflows to maximize productivity.

Innovations are also visible in mold design. 3D printing allows for faster prototyping and improvements. It pushes the boundaries of what can be achieved in mold making. However, some manufacturers may face challenges adapting to these technologies. Resistance to change can slow down implementation. Being open-minded is crucial for progress.

Tips: Regularly assess your production processes. Identify areas for improvement with automation. It can help save time and resources in the long run. Reflection is key. Embrace the possibility of making mistakes as a part of the learning curve.

2026 How to Master Injection Molding Techniques for Efficient Production? - Emerging Technologies in Injection Molding: Automation and Innovations

| Technique | Description | Advantages | Challenges | Emerging Technologies |

|---|---|---|---|---|

| Multi-material Injection Molding | Combining different materials in a single mold to achieve varied properties. | Enhanced product functionality and aesthetics. | Complex mold design and higher production costs. | Advanced robotics for precise layering. |

| 3D Printing of Injection Molds | Utilizing 3D printing technology to create molds quickly. | Reduced lead times and customization capabilities. | Material limitations and surface finish considerations. | Integration with CAD software for design. |

| Hot Runner Systems | Molds designed to keep plastic molten before injection. | Reduced waste and cycle time. | Higher initial investment and maintenance effort. | Smart temperature control systems. |

| Robotic Automation | Use of robots for handling and assembly processes. | Increased efficiency and reduced labor costs. | Higher upfront costs and technical expertise required. | AI and machine learning for process optimization. |

Related Posts

-

Why Is Injection Molding the Best Choice for Prototyping and Production

-

Why Injection Molding is Essential for Modern Manufacturing Success

-

Top 10 Benefits of Using Injection Molding Machines in Manufacturing

-

The Best 10 Tips for Optimizing Injection Tooling Efficiency

-

Top 10 Tips for Choosing the Best Plastic Injection Molding Machine

-

2026 Top Trends in Protomold Injection Molding Technology?