What is Medical Injection Moulding and its Benefits in Healthcare

Medical injection moulding is revolutionizing the healthcare industry by providing precise and efficient manufacturing solutions for medical devices and components. According to a recent report by Research and Markets, the global medical injection molding market is projected to reach USD 6.2 billion by 2025, growing at a compound annual growth rate (CAGR) of 8.4%. This growth is driven by the increasing demand for high-quality, low-cost medical products that can be produced at scale, which medical injection moulding uniquely offers.

The benefits of medical injection moulding extend far beyond mere cost-effectiveness. This technology allows for the production of complex geometries and high tolerance components essential for medical applications, such as surgical instruments, drug delivery systems, and diagnostic devices. In addition, a study by the Medical Device Manufacturers Association highlights that the capability of injection moulding to ensure consistent quality and reproducibility significantly reduces the risk of defects, which is critical in a field where precision can be a matter of life and death. Furthermore, the process supports the integration of multiple functions into a single component, ultimately streamlining manufacturing and minimizing waste. As the healthcare sector continues to evolve, medical injection moulding remains at the forefront, shaping the future of medical device manufacturing.

What is Medical Injection Moulding?

Medical injection moulding is a precise manufacturing process used to produce components and devices specifically for healthcare applications. This method involves injecting molten plastic or other materials into a mould to create intricate and highly detailed medical products. Common examples include syringes, surgical instruments, and various types of medical packaging. One of the key advantages of medical injection moulding is its ability to produce items in high volumes while maintaining consistent quality, making it essential for medical facilities that require reliable and disposable products.

Tips: When considering medical injection moulding for your healthcare product, it’s crucial to collaborate with experienced manufacturers who understand the specific regulatory requirements of the medical industry. Ensure that they implement stringent quality control measures throughout the production process to meet safety standards.

Moreover, the versatility of medical injection moulding allows for the use of various materials, which can be specially formulated for specific applications, such as biocompatibility for implants. This adaptability means that new innovations can be quickly prototyped and mass-produced, significantly speeding up the time it takes to bring new healthcare solutions to market. Keeping abreast of the latest advancements in materials and moulding technology can also enhance product performance and patient safety.

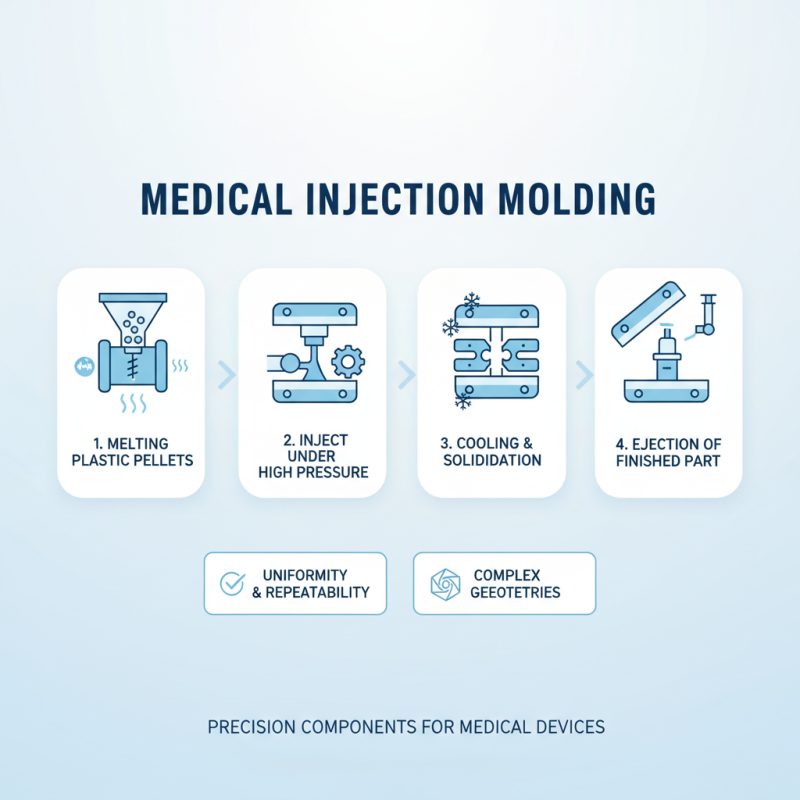

The Process of Medical Injection Moulding Explained

Medical injection moulding is a crucial manufacturing process in the healthcare sector, allowing for the production of intricate and high-precision plastic components used in medical devices and tools. The process begins with the melting of plastic pellets, which are then injected into a mould under high pressure. Once cooled, the mould is opened to release the finished part. This method not only ensures uniformity and repeatability but also facilitates the creation of complex geometries that are often required in medical applications.

Tips for successful medical injection moulding include ensuring proper quality control measures are in place throughout the process. This includes regular inspections of the moulds to prevent defects and maintaining optimal temperature and pressure settings for the injected material. Additionally, choosing the right type of polymer is essential as it can impact the durability, safety, and performance of the final product.

Another important aspect is maintaining cleanroom standards during production. Contaminants can compromise the sterility of medical devices, making it vital to have rigorous cleaning protocols and controlled environments in place. By following these best practices, manufacturers can enhance the quality and reliability of their medical products, ultimately benefiting patient care.

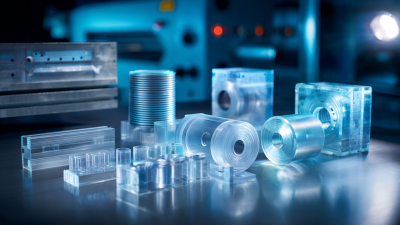

Key Materials Used in Medical Injection Moulding

Medical injection moulding is a critical process in the healthcare industry, providing precision-engineered plastic components for various applications. Key materials used in this process include thermoplastics and thermosetting polymers, which are selected for their biocompatibility, strength, and flexibility. For example, polystyrene and polycarbonate are popular choices due to their excellent clarity and impact resistance, making them ideal for medical devices such as syringes and IV components.

Reports from industry analysts indicate that the global medical injection moulding market is projected to reach approximately USD 5.4 billion by 2025, with a compound annual growth rate (CAGR) of around 7%. This growth is driven by the increasing demand for cost-effective and high-quality medical devices. Advanced polymers like PEEK (Polyether ether ketone) and TPU (Thermoplastic Polyurethane) have also gained traction due to their superior performance in demanding medical applications. These materials not only enhance product durability but also improve patient safety by minimizing the risk of contamination and ensuring consistent performance in critical healthcare environments.

What is Medical Injection Moulding and its Benefits in Healthcare - Key Materials Used in Medical Injection Moulding

| Dimension | Description | Key Materials | Benefits |

|---|---|---|---|

| Process | Technique for manufacturing plastic parts. | Polypropylene (PP) | Versatile and cost-effective. |

| Applications | Used for creating medical devices and components. | ABS (Acrylonitrile Butadiene Styrene) | Durable and impact-resistant. |

| Quality | Ensures precision and consistency in production. | Polycarbonate (PC) | High transparency and strength. |

| Regulatory Compliance | Adheres to healthcare regulations and standards. | Polyethylene (PE) | Lightweight and flexible. |

| Scalability | Easily scalable for mass production. | Silicone | Biocompatible and flexible. |

Advantages of Medical Injection Moulding in Healthcare Applications

Medical injection moulding is a highly specialized manufacturing process that plays a pivotal role in the healthcare sector. This technique allows for the production of intricate plastic components that are essential for various medical applications, including surgical instruments, drug delivery systems, and diagnostic devices. One of the primary advantages of medical injection moulding is its ability to create highly precise and consistent parts. The exactness of the moulding process ensures that each product meets stringent regulatory standards, which is crucial for patient safety and efficacy.

Another significant benefit of medical injection moulding is its efficiency in mass production. This method not only reduces waste due to its high material utilization rate but also speeds up the manufacturing cycle, allowing healthcare providers to receive products more quickly. Moreover, the versatility of materials used in injection moulding enables the production of components with various properties, such as biocompatibility and durability, catering specifically to the demanding needs of the medical field. These advantages make medical injection moulding an invaluable technique in the continual advancement of healthcare technologies.

Case Studies of Medical Injection Moulding in the Industry

Medical injection moulding is revolutionizing the healthcare industry, bringing efficiency and precision to the manufacturing of medical devices. Case studies illustrate how this technique is essential for producing components such as syringes, surgical instruments, and housings for diagnostic equipment. For instance, a notable case involved the production of a line of disposable syringes where injection moulding reduced production time by 30% while maintaining stringent quality standards. According to a report from the British Plastics Federation, the demand for injection-moulded medical products is projected to grow at a CAGR of 6.5% over the next five years, underscoring its significance in healthcare advancements.

In another case, the manufacturing of complex drug delivery systems demonstrated the flexibility of injection moulding in creating intricate designs that are essential for modern therapies. This method allows for the integration of multiple functionalities, reducing assembly time and potential error rates. Research from Grand View Research indicates that the global medical injection moulding market was valued at approximately USD 2.6 billion in 2021 and is expected to continue to expand, illustrating the growing importance of this technology in enhancing patient care and operational efficiency in healthcare.

Tips: Consider implementing injection moulding in your production processes if you're looking to improve precision and scalability. Additionally, collaborating with experts in the field can help optimize designs for better functionality and compliance with regulatory standards, maximizing the benefits of this innovative manufacturing technique.

Related Posts

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

10 Essential Tips for Working with Injection Moldable Plastics

-

Top Benefits of Medical Injection Moulding for Healthcare Innovations

-

2025 Guide: How to Calculate Injection Molding Mold Costs Effectively

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development