The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

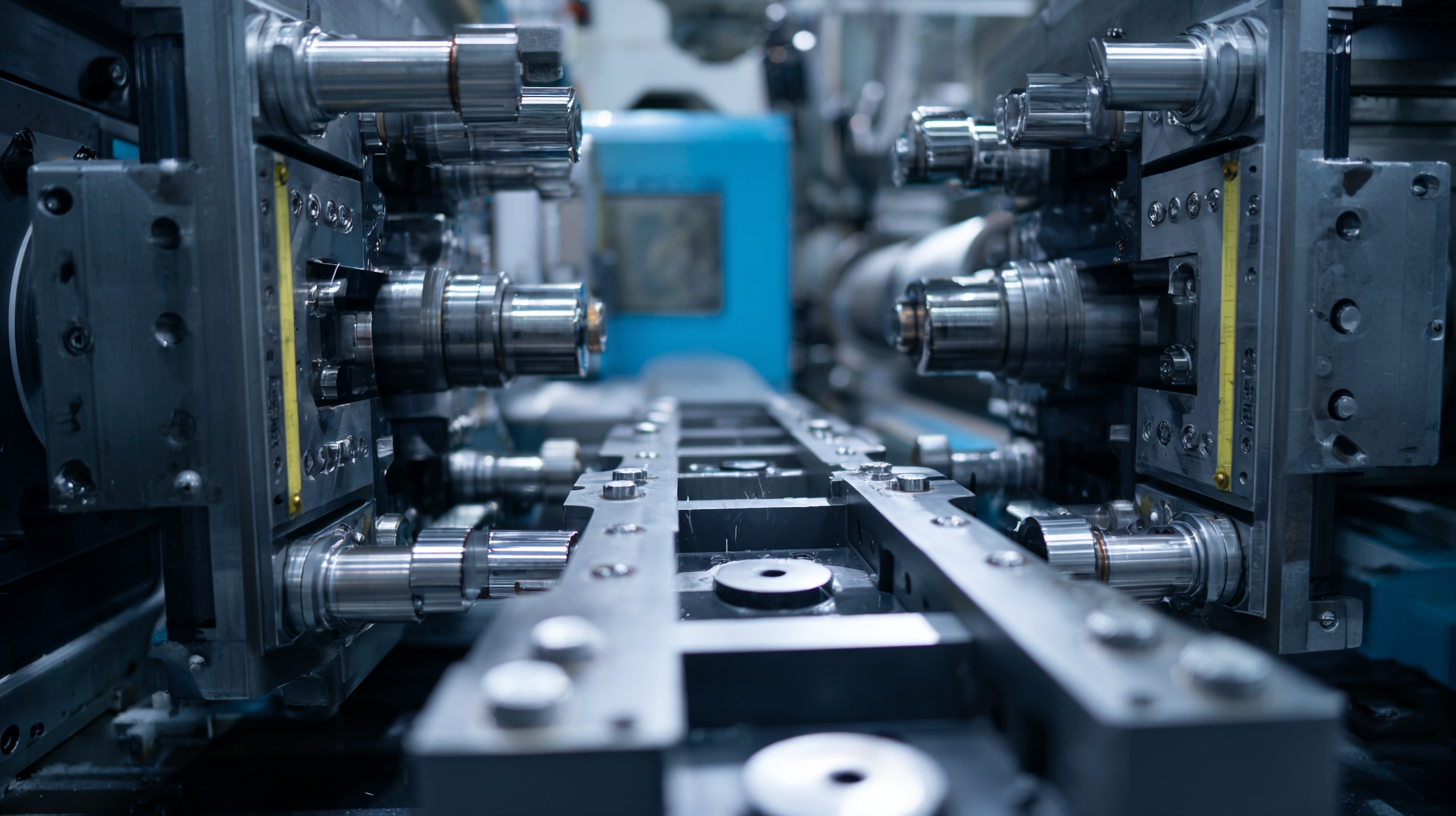

In the rapidly evolving manufacturing landscape, a profound transformation is taking place, driven by the advent of cutting-edge technologies that enhance efficiency and productivity. At the forefront of this revolution is the injection molding machine, a pivotal tool reshaping production processes across various industries. By allowing for precise manufacturing of complex components with minimized waste, injection molding machines are not only improving product quality but also significantly reducing production times and costs.

As businesses strive to keep pace with the growing demand for customized and high-quality products, the injection molding machine emerges as a critical player in driving innovation and competitive advantage. This exploration of the future of manufacturing will delve into how injection molding technology is setting new benchmarks in production capabilities, propelling industries towards a more sustainable and efficient future.

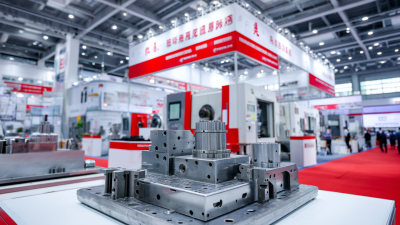

The Growing Demand for Injection Molding in the Global Market

The global injection molding market is on a trajectory of robust growth, with projections indicating it will reach USD 365.22 billion by 2024. This expansion is fueled by the rising demand for injection molding across various industries, particularly in the production of lightweight and precise components. As manufacturers seek to streamline operations and reduce costs, the shift towards injection molding technologies is becoming more pronounced.

Tips for embracing this trend include investing in advanced machinery that enhances efficiency and reduces cycle times. Additionally, exploring the benefits of 3D injection-molded plastics can lead to innovations in product design. As industries leverage these technologies, they can not only meet market demands but also stay ahead of the competitive curve.

With the plastic injection molding market expected to surpass USD 17.65 billion by 2034, it’s essential for companies to adapt to these growing trends. Assessing different materials and technologies will empower businesses to innovate and meet consumer needs effectively. Engaging with the latest advancements will ensure manufacturers capitalize on the lucrative opportunities presented in the global market.

Advancements in Technology Driving Efficiency in Injection Molding Machines

Advancements in technology are significantly transforming the injection molding industry, enhancing efficiency and productivity. According to a report by MarketsandMarkets, the global injection molding machine market is projected to grow from $17.5 billion in 2020 to $24.5 billion by 2025, at a compound annual growth rate (CAGR) of 7.3%. This surge is driven by the increased demand for lightweight and high-performance materials across various sectors, including automotive, healthcare, and consumer goods.

Recent innovations in injection molding technology, such as the integration of Industry 4.0 principles, have led to the development of smarter machines equipped with IoT capabilities. These machines can monitor their performance in real-time, predict maintenance needs, and optimize production schedules. A study by the American Society of Mechanical Engineers (ASME) revealed that manufacturers utilizing smart injection molding technologies have achieved up to 25% reduction in cycle times and a 40% decrease in energy consumption. Such advancements not only enhance operational efficiency but also contribute to sustainability efforts within the manufacturing sector.

The Future of Manufacturing: Efficiency of Injection Molding Machines

This chart illustrates the increasing efficiency of injection molding machines from 2018 to 2023, showcasing how advancements in technology are transforming production in the manufacturing sector.

Sustainability and Environmental Impact of Modern Injection Molding Practices

The sustainability and environmental impact of modern injection molding practices are becoming increasingly significant as the industry evolves. With projections indicating that the plastic injection molding market will grow to USD 17.65 billion by 2034, it is imperative for manufacturers to adopt eco-friendly practices. Companies are now focusing on sustainability by utilizing biodegradable materials and innovative processes that minimize waste. For instance, exploring plant-based polymer additives not only reduces reliance on fossil fuels but also meets the rising demand for environmentally responsible production methods.

Implementing eco-conscious strategies can enhance the reputation of manufacturing businesses while also catering to the growing consumer base that prioritizes sustainability. Tips for manufacturers include investing in advanced recycling technologies and evaluating metal injection molding as a greener alternative. Additionally, integrating smart, scalable biomanufacturing techniques can position companies at the forefront of sustainability, meeting industry standards and consumer expectations alike. As advancements continue, manufacturers must remain vigilant about their environmental impact and strive for continuous improvement in sustainable practices.

Comparative Cost Analysis: Traditional Manufacturing vs. Injection Molding

In the realm of production, a comparative cost analysis reveals key advantages of injection molding over traditional manufacturing methods. Traditional techniques often entail higher labor costs, material waste, and extended lead times, which can inflate overall expenses. In contrast, injection molding machines streamline the process, ensuring consistent quality and minimal waste. The initial investment in these advanced machines may seem substantial, but the cost efficiencies accrued through rapid production cycles and reduced labor requirements can lead to significant savings over time.

Tips: When considering the transition to injection molding, assess the potential volume of production. This can help determine whether the initial investment is justifiable. Additionally, explore options for automation within the injection molding process to further reduce costs and improve efficiency.

Moreover, the flexibility of injection molding allows for rapid design changes without extensive retooling, making it an ideal choice for companies aiming to adapt quickly to market demands. Traditional methods may require lengthy downtime for modifications, which can hinder productivity and competitiveness. By embracing injection molding, manufacturers can position themselves as agile producers in a fast-evolving landscape.

Tips: Keep an eye on technological advances in injection molding that may enhance performance or reduce costs even further. Investing in training for your workforce can also maximize the capabilities of new machinery and improve the overall production process.

Future Trends in Injection Molding: Automation and Smart Manufacturing Integration

The injection molding industry is on the brink of a significant transformation, driven by the integration of automation and smart manufacturing technologies. As the LIM (Liquid Injection Molding) and LSR (Liquid Silicone Rubber) injection molding machine market is projected to grow from $159.5 million in 2024 to $283.83 million by 2032, with a robust CAGR of 7.47%, the emphasis on innovative production methods becomes even more critical. Automated processes enhance efficiency, reduce waste, and allow for greater precision, making manufacturing more sustainable.

To take advantage of this trend, companies should invest in advanced technologies that facilitate real-time data collection and analysis. This empowers manufacturers to monitor performance and make adjustments swiftly, leading to optimized operations.

Tips for businesses include prioritizing training for staff on new technologies and ensuring that maintenance schedules are aligned with automated systems. Continuous evaluation of production techniques can also uncover areas where smart manufacturing integration can yield further improvements in quality and efficiency. Embracing these future trends will not only help companies stay competitive but also pave the way for innovative solutions in production.

Related Posts

-

Understanding the Evolution of Injection Molding Machines: Key Innovations Driving Efficiency in 2023

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Impact of Injection Molding Cost Trends on Businesses Exhibiting at the 138th Canton Fair 2025

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Revolutionizing Production: The Future of Molding Machines in Advanced Manufacturing