The Best 10 Tips for Optimizing Injection Tooling Efficiency

In the competitive landscape of manufacturing, optimizing injection tooling efficiency is a critical factor that can significantly impact production costs and overall product quality. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $331 billion by 2026, highlighting the growing relevance of advanced techniques in injection tooling to meet evolving industry demands. With such significant potential for market growth, manufacturers are increasingly looking for ways to enhance their injection tooling processes to maximize productivity and minimize waste.

Industry expert Dr. Samuel Greene, a renowned figure in polymer science, emphasizes the importance of efficiency in injection tooling by stating, "The key to driving down costs and improving quality lies in understanding and optimizing every aspect of the injection tooling process." As manufacturers strive to adopt innovative practices, drawing on established best practices becomes essential. By implementing strategies focused on improving cycle times, reducing defects, and streamlining maintenance, organizations can not only boost their operational efficiency but also ensure higher customer satisfaction and retention in a thriving market.

In this context, the following ten tips are designed to help manufacturers refine their approach to injection tooling, promoting both enhanced productivity and sustainability in a rapidly evolving industry.

Understanding Injection Tooling: Basics and Importance

Injection tooling plays a vital role in the production process of various plastic components, making it crucial to understand its basics and significance. At its core, injection tooling involves creating molds used in the injection molding process, where molten plastic is injected into a mold to form specific shapes. The complexity of a part directly influences the tooling design, as factors like material choice, cooling efficiency, and mold finish must be considered to ensure optimal performance. A well-designed injection tool can significantly enhance production efficiency, reduce waste, and ultimately lead to cost savings.

The importance of injection tooling extends beyond just the creation of parts; it encompasses the entire manufacturing cycle. Tools that are optimized for efficiency can lead to faster cycle times, improved part quality, and minimized downtime. Understanding the nuances of tooling, such as proper maintenance and the integration of advanced technologies like 3D printing for prototypes, is essential for manufacturers looking to stay competitive. By focusing on these fundamentals, companies can harness the full potential of injection molding, ultimately driving innovation and improving their manufacturing processes.

Key Factors Influencing Injection Tooling Efficiency

When it comes to optimizing injection tooling efficiency, it's essential to consider several key factors that significantly influence performance. One of the primary components is the design of the injection mold itself. A well-optimized mold design takes into account not only the part geometry but also the material flow and cooling channels. This ensures that the molten material fills the mold uniformly, minimizing defects and reducing cycle times. Proper mold design can lead to improved part consistency and a decrease in manufacturing costs over time.

Another crucial factor is the selection of materials used in the tooling process. The choice of high-performance materials can elevate the longevity and efficiency of the molds, ultimately leading to reduced downtime and maintenance costs. Additionally, incorporating advanced coatings can enhance wear resistance and thermal stability, which play a vital role in sustaining production rates. Furthermore, regular maintenance and cleaning of the injection machinery and molds ensure optimal performance, as buildup or wear can directly impact cycle times and part quality. By focusing on these critical areas, manufacturers can significantly boost their injection tooling efficiency.

The Best 10 Tips for Optimizing Injection Tooling Efficiency

Techniques for Reducing Cycle Time in Injection Molding

Reducing cycle time in injection molding is crucial for enhancing productivity and maximizing profitability in manufacturing processes. According to a report from the Plastics Industry Association, optimizing cycle times can increase output by up to 20%, significantly impacting the bottom line. Streamlining operations through various techniques not only boosts efficiency but also ensures that molds are utilized to their maximum potential.

One effective tip for reducing cycle time is optimizing the cooling system. Implementing advanced cooling techniques, such as conformal cooling channels, can reduce heat loss and decrease the time required for parts to sufficiently cool before ejection. Studies indicate that effective cooling can cut cycle times by as much as 25%. Additionally, using temperature control units can help maintain a stable environment, which contributes to consistent molding temperatures and reduced cycle times.

Another critical factor is the careful selection of materials. By choosing materials that offer quicker solidification rates, companies can minimize waiting times in the cycle. The American Society for Testing and Materials has reported that specific high-performance polymers can achieve faster cycle times compared to traditional thermoplastics. Furthermore, employing automated systems for part removal can expedite the overall process, allowing for quicker transitions between cycles and improving overall production rates.

The Best 10 Tips for Optimizing Injection Tooling Efficiency - Techniques for Reducing Cycle Time in Injection Molding

| Tip Number | Optimization Tip | Description | Expected Cycle Time Reduction (%) |

|---|---|---|---|

| 1 | Use High-Quality Materials | Selecting premium raw materials can enhance the tooling longevity and reduce defects, decreasing cycle times. | 10% |

| 2 | Optimize Mold Design | Improving the mold design for better flow can significantly reduce the cooling time. | 15% |

| 3 | Maintain Consistent Temperature | Implementing precise temperature controls can minimize cycle variability and enhance quality. | 8% |

| 4 | Reduce Clamp Time | Analyzing and reducing clamp time while ensuring part integrity can effectively shorten cycle times. | 12% |

| 5 | Implement Automation | Using automated systems to handle repetitive tasks can speed up operations significantly. | 20% |

| 6 | Regular Maintenance of Equipment | Frequent inspection and maintenance of machinery can decrease downtime and enhance productivity. | 5% |

| 7 | Optimize Injection Speed | Adjusting the injection speed to match material flow characteristics can improve cycle efficiency. | 18% |

| 8 | Use of Hot Runner Systems | Incorporating hot runner systems can reduce material waste and cycle time compared to cold runners. | 25% |

| 9 | Enhance Operator Training | Well-trained operators can quickly address issues, thus reducing cycle interruptions. | 7% |

| 10 | Evaluate and Adjust Parameters Regularly | Continuous evaluation and adjustment of the molding parameters help maintain optimal performance. | 9% |

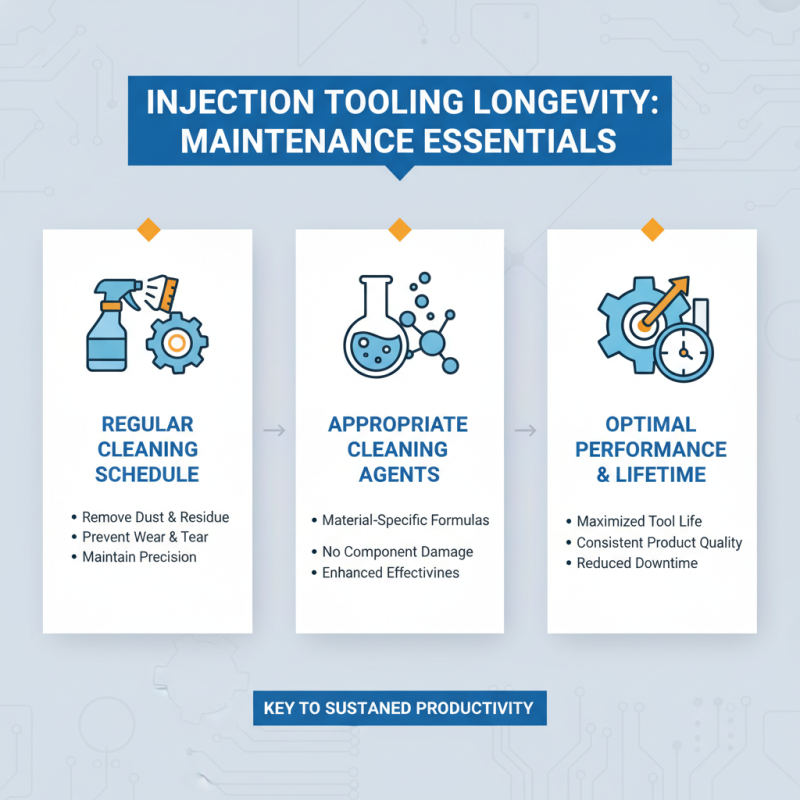

Maintenance Practices for Maximizing Tool Longevity

Proper maintenance practices are essential for maximizing the longevity of injection tooling and ensuring optimal performance throughout its operational lifetime. One of the key strategies is to implement a regular cleaning schedule. Contaminants such as dust, residue from past materials, and lubrication buildup can significantly affect the precision of the tooling. Adopting a systematic cleaning protocol reduces wear and tear and helps maintain the tooling’s specifications. Additionally, utilizing appropriate cleaning agents that are suitable for the specific materials used in the tooling can enhance maintenance effectiveness without damaging the components.

Another critical aspect of maintenance is inspection. Regularly scheduled inspections allow operators to identify potential weaknesses or signs of wear before they escalate into significant issues. During these inspections, examining the molds for surface imperfections, cracking, or misalignment is vital. Implementing predictive maintenance techniques using advanced technology, such as sensors and data analytics, can further enhance the inspection process, allowing for timely interventions before failures occur. By prioritizing these maintenance practices, manufacturers can significantly extend the life of their injection tooling, resulting in improved efficiency and reduced operational costs in the long run.

Analyzing Material Selection for Optimal Tool Performance

When it comes to optimizing injection tooling efficiency, the selection of materials plays a critical role in the performance and longevity of the tooling. According to the Plastics Industry Association, more than 90% of manufacturers report that material choice directly influences not only the cycle times but also the quality of the final product. Materials such as tool steel, aluminum, and specialty alloys each have unique properties that can enhance heat resistance and corrosion resistance, which are crucial for maintaining precision during high-volume production runs.

Additionally, recent studies have shown that advancements in material science have led to the development of high-performance composites that can withstand harsh manufacturing environments while reducing weight and improving thermal conductivity. For instance, research published in the Journal of Manufacturing Science and Engineering highlights that using advanced polymer composites can improve tool life by up to 30%, thus reducing downtime and maintenance costs. This shift towards more strategic material selection not only maximizes tooling efficiency but also contributes to a more sustainable manufacturing process by minimizing waste and energy consumption associated with frequent tool replacements.

Related Posts

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

Why Injection Molding is Essential for Modern Manufacturing Success

-

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Understanding the Injection Molding Process for Sustainable Product Development