Why Understanding Injection Molding Cost is Crucial for Optimizing Production Efficiency and Budgeting

In today's competitive manufacturing landscape, understanding injection molding cost is crucial for businesses aiming to optimize production efficiency and budget allocation. According to a report by Market Research Future, the global injection molding market is projected to reach approximately $345 billion by 2026, highlighting the significant role this process plays in various industries, including automotive, healthcare, and consumer goods. With increasing demand for customized solutions and rapid production capabilities, manufacturers must carefully evaluate the costs associated with injection molding to remain viable and competitive.

Furthermore, a survey conducted by the Plastics Industry Association revealed that managing costs effectively can lead to a reduction in production times by up to 30%. Companies that prioritize an in-depth analysis of injection molding costs—considering aspects such as material expenses, cycle times, labor, and equipment maintenance—are better positioned to allocate resources wisely. This awareness not only aids in budgeting but also enhances overall production strategies, fostering long-term success in a market where efficiency and cost-effectiveness are paramount.

Ultimately, mastery of injection molding cost is not merely an operational concern; it is a strategic imperative that can significantly influence a company's profitability and growth trajectory.

Understanding the Components of Injection Molding Costs

Understanding the components of injection molding costs is essential for manufacturers aiming to optimize both production efficiency and budgeting. Injection molding is a complex process, and its costs can significantly vary based on several factors. Key components include material costs, labor, overhead, machine time, and tooling expenses. Each of these aspects plays a critical role in determining the overall production expenses and should be carefully analyzed during the planning stages.

One tip is to conduct a comprehensive cost analysis before starting production. This should include evaluating different materials that can impact both functionality and cost, as well as exploring various suppliers to find the best pricing options. Another important consideration is the tooling costs; opting for high-quality molds can lead to fewer defects and reduce the need for costly rework. Maintaining a close relationship with your manufacturers can also provide insights into potential cost-saving measures throughout the injection molding process. By understanding these components, businesses can make informed decisions that enhance their bottom line while maintaining high production standards.

Evaluating Material Selection and Its Impact on Budgeting

When it comes to injection molding, material selection plays a pivotal role in budgeting and overall production efficiency. Different materials come with varying costs, properties, and availability, which can significantly influence the total expenditure. For instance, high-performance polymers might offer superior durability for specific applications but could also drive up costs considerably compared to standard plastics. Evaluating the desired end-use of the molded part can help in identifying the best material that balances performance and budget constraints.

**Tips:** Always conduct a cost-benefit analysis when selecting materials. Consider not only the purchase price of the material but also factors such as processing times, scrap rates, and the potential need for additional treatments or finishing. Collaborating with suppliers who understand your specific needs can also lead to discovering affordable alternatives that don't compromise on quality.

Additionally, keep in mind that the choice of material can affect production efficiency. Inconsistent material quality can lead to increased defects and downtime, impacting overall productivity. Assessing the supply chain for reliable sourcing can further mitigate risks and ensure a smoother production process.

**Tips:** Regularly evaluate your material suppliers and explore new options to stay updated on innovations and pricing trends. Engaging in long-term relationships with dependable suppliers can also unlock discounts and improve material quality consistency, thus enhancing your project's cost-effectiveness.

Analyzing Labor and Overhead Expenses in Production Efficiency

Understanding labor and overhead expenses is vital for optimizing production efficiency, especially in industries like injection molding. Labor costs can account for up to 70% of total business expenses, making it critical for manufacturers to analyze and manage these costs effectively. By examining labor expenditures, companies can identify areas for improvement, implement more efficient practices, and refine their budgeting strategies. This not only ensures that resources are allocated wisely but also enhances workforce productivity, leading to improved production outcomes.

Additionally, overhead expenses, which include utilities, maintenance, and administrative costs, play a significant role in the overall cost structure of manufacturing operations. As businesses strive for cost efficiency, the integration of advanced technologies and streamlined processes becomes essential. Embracing innovative solutions, including artificial intelligence, can help managers optimize operations, reduce waste, and ultimately enhance the bottom line. By focusing on both labor and overhead costs, manufacturers can create a more robust framework for production efficiency, ensuring they remain competitive in a rapidly evolving market.

Exploring Techniques to Reduce Overall Injection Molding Costs

Understanding how to reduce injection molding costs is vital for manufacturers aiming to enhance production efficiency without compromising on quality. One effective technique is to optimize the design of the molded parts. By simplifying shapes and reducing unnecessary features, manufacturers can minimize material usage and time spent on production. Implementing design for manufacturability (DFM) principles allows for the creation of parts that not only meet functional requirements but are also easier and cheaper to produce.

Another approach is to select the right materials and processes. Utilizing materials that offer favorable processing characteristics and lower raw material costs can significantly impact the overall budget. Additionally, automating certain processes and investing in high-efficiency machinery can reduce labor costs and increase throughput. Adopting advanced technologies, such as real-time monitoring systems, can also help identify inefficiencies in the production process, enabling timely adjustments that save money and time. By focusing on these techniques, manufacturers can achieve substantial savings and improve their competitive edge in the market.

Injection Molding Cost Analysis

The Role of Process Optimization in Enhancing Profit Margins

Effective process optimization is a pivotal component in enhancing profit margins within the injection molding industry. According to the 2022 report by Grand View Research, the global injection molding market size is expected to reach $411.4 billion by 2028, which highlights the competitive nature of this sector. Implementing advanced techniques like just-in-time manufacturing and lean production can significantly reduce waste and streamline operations. For instance, utilizing simulation software for mold design can minimize trial-and-error phases, leading to a 30% reduction in development time, allowing manufacturers to respond quickly to market demands.

Moreover, continuous monitoring and analysis of production metrics are vital for maintaining efficiency. A study published in the Journal of Manufacturing Science and Engineering found that manufacturers who adopted real-time data analytics improved their production yield by up to 20%. By identifying bottlenecks and inefficiencies, businesses can take corrective actions that not only cut costs but also enhance product quality, thereby increasing customer satisfaction and loyalty. In an era where margins are thin, understanding and optimizing every aspect of the injection molding process is no longer optional but essential for sustainable growth.

Related Posts

-

The Future of Manufacturing How Injection Molding Machines are Revolutionizing Production

-

Understanding the Future of Injection Molding Materials: Innovations and Trends You Need to Know

-

Understanding the Advantages of Injection Molding in Canada's Manufacturing Industry

-

Understanding the Injection Molding Process for Sustainable Product Development

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

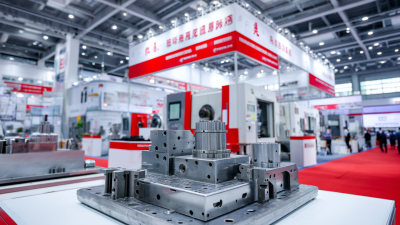

Exploring Opportunities for Injection Molded Parts at the 2025 China 138th Import and Export Fair