2026 Top Trends in Protomold Injection Molding Technology?

The landscape of manufacturing is rapidly evolving. Protomold injection molding serves as a crucial component in this shift. According to a recent report by Smithers Pira, the global injection molding market is projected to witness an annual growth rate of 4.5% through 2026.

Protomold injection molding technology has revolutionized rapid prototyping and production. It allows designers and engineers to create complex parts quickly and efficiently. In less than a week, prototypes can be delivered to clients. This speed meets market demands effectively but raises questions about quality control. High production rates can sometimes compromise detail, leading to imperfect results.

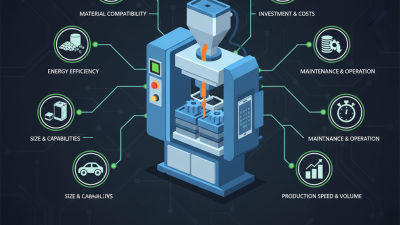

As companies adopt protomold injection molding, they face unanticipated challenges. Equipment costs may rise with advanced technology. The need for skilled operators increases, highlighting a skills gap in the workforce. These factors complicate the promise of efficiency. The urgent need to balance speed and quality is crucial for sustained success in the industry.

Emerging Technologies in Protomold Injection Molding for 2026

The protomold injection molding technology landscape is poised for dramatic changes by 2026. Emerging technologies are shaping this industry, driven by the demand for efficiency and sustainability. A recent report by the Association for Manufacturing Technology indicates that the injection molding market may grow by 4.5% annually over the next five years. This statistic emphasizes the significance of staying updated on advancements in the field.

Automation and robotics stand at the forefront of these developments. Companies are increasingly integrating automated systems to enhance precision and reduce cycle times. Predictions suggest a 30% increase in productivity due to automation by 2026. However, challenges such as workforce training and system integration need addressing. Companies must evaluate whether they are ready to adapt to these changes.

Another critical trend is the focus on sustainable materials. The use of biodegradable and recycled plastics is gaining traction. The sustainable packaging segment is projected to reach $413 billion by 2027. Yet, the shift toward green materials may lead to compromise in performance. Balancing sustainability with functional requirements remains a pressing issue. This will require ongoing research and innovation to meet diverse customer needs effectively.

Sustainable Materials and Processes in Protomold Manufacturing

The rise of sustainable materials in protomold injection molding technology is significant. Manufacturers are now prioritizing eco-friendly options. Biodegradable plastics and recycled materials are gaining traction. These alternatives help reduce waste and environmental impact.

Incorporating sustainable practices is vital. One effective approach is to analyze the life cycle of materials. This assessment aids in choosing the most environmentally friendly options. However, it is important to note that not all “green” materials perform the same under various conditions. Testing is key.

Tips: When selecting materials, consider their sourcing and recyclability. Engaging in discussions with suppliers can unveil the best eco-friendly choices. Additionally, developing a more efficient production process can minimize energy use. Aim for a balance between sustainability and product performance. Small adjustments can lead to significant changes.

2026 Trends in Protomold Injection Molding Technology

This chart illustrates the projected adoption of sustainable materials and processes in Protomold injection molding technology by 2026. It highlights the shift towards eco-friendly solutions in the manufacturing sector.

Automation and AI Integration in Protomold Injection Molding

The integration of automation and AI in protomold injection molding is transforming the industry. Automation streamlines processes, reducing manual labor and speeding up production. Robots can handle repetitive tasks with precision. This not only enhances efficiency but also improves safety on the factory floor.

AI plays a vital role in optimizing production. Machine learning algorithms analyze data to predict equipment failures. This proactive approach minimizes downtime. Yet, reliance on AI requires skilled operators who can navigate the technology. It raises questions about training and the skill gap that may emerge.

While automation and AI offer great benefits, challenges persist. Not all facilities can afford the latest technology. Smaller businesses might struggle to keep up. Finding the right balance between automation and human touch is crucial. It's essential to reflect on how these advancements can coexist with traditional methods. The future of protomold injection molding looks promising, but it demands thoughtful implementation.

Customization Trends for Prototyping in Injection Molding

Customization is becoming increasingly essential in injection molding technology. As industries evolve, the demand for tailored solutions grows. Reports indicate that around 70% of manufacturers now prioritize customization in prototyping. This shift signifies a changing landscape in product development.

In 2026, we can expect significant advancements in prototyping methods. Enhanced software tools will facilitate intricate designs. However, many companies still use outdated techniques, resulting in inefficiencies. It’s crucial to adopt new technologies rather than cling to the old.

Moreover, the rise of small batch production is challenging traditional methods. While it enables flexibility, it can lead to production inconsistencies. Companies must find a balance between speed and quality. As injection molding progresses, the focus on customization will redefine prototyping. Challenges remain, but opportunities abound for those willing to adapt.

2026 Top Trends in Protomold Injection Molding Technology

| Trend | Description | Impact on Prototyping | Customization Level |

|---|---|---|---|

| Automation in Injection Molding | Increased use of robotics and AI for precision and efficiency. | Reduces lead time and improves accuracy in prototypes. | High |

| Sustainable Materials | Shift towards biodegradable and recyclable materials in molding processes. | Allows for eco-friendly prototypes and reduces waste. | Medium |

| Advanced CAD/CAE Integration | Enhanced software tools for design and analysis, leading to improved prototypes. | Enables rapid iteration and improved design accuracy. | High |

| 3D Printing and Hybrid Technologies | Integration of 3D printing with traditional molding techniques for rapid prototyping. | Accelerates prototype development and allows for complex designs. | Very High |

| Data-Driven Decision Making | Use of big data analytics to optimize processes and outcomes in injection molding. | Improves efficiency and outcome predictability of prototypes. | Medium |

Quality Control Innovations in Protomold Injection Techniques

Quality control in protomold injection techniques has advanced significantly in recent years. Industry reports show that over 80% of manufacturers are now using automated inspection systems. These innovations help ensure consistent product quality and reduce defects. The use of IoT-enabled sensors allows for real-time monitoring of the injection molding process. This enables immediate adjustments, leading to a decrease in production errors by approximately 30%.

Tips for effective quality control: Regularly calibrate your machines. This ensures they operate within specified tolerances. Conduct routine training for staff. A well-trained team can identify issues faster, minimizing downtime. Finally, consider implementing a feedback loop with your design teams. Continuous feedback can improve the design process and enhance overall quality.

While technology advances, challenges remain. The reliance on automation can cause complacency. Employees might overlook manual checks. Data reports highlight that some manufacturers still face significant quality issues. A balanced approach combining technology and human oversight is essential. This ensures superior quality control in protomold injection molding.

Related Posts

-

The Best 10 Tips for Optimizing Injection Tooling Efficiency

-

Exploring the Future of Injection Molding Materials: Innovations and Trends Shaping the Industry

-

10 Essential Tips for Effective Rapid Injection Molding Techniques?

-

10 Best Plastic Injection Molding Machines for Quality Production?

-

Understanding the Benefits of Prototype Injection Molding for Fast Product Development

-

Top 10 Benefits of Using Injection Molding Machines in Manufacturing