2026 Top Trends in Injection Molding Process for Industry Innovations

The injection molding process plays a critical role in modern manufacturing. This method shapes materials into specific forms, allowing for mass production. In 2026, we expect to see transformative trends emerge within this field. Innovations promise to enhance quality, efficiency, and sustainability.

Advancements in technology will drive these changes. For example, improved software systems will allow for better design and analysis. Furthermore, newer materials may increase the speed and versatility of production. However, with these improvements come challenges. Companies must adapt to new processes, which can be a steep learning curve. Resistance to change can hinder progress.

As the industry evolves, collaboration becomes essential. Engaging with experts and stakeholders will highlight opportunities. By embracing innovative trends in the injection molding process, manufacturers can thrive. Yet, success requires continuous reflection and adaptation. The path to improvement is not always clear, but the potential is undeniable.

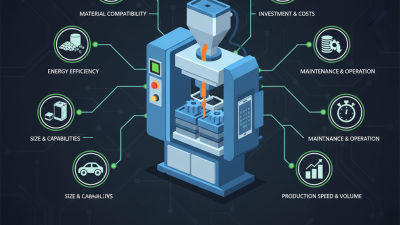

Key Driving Factors Behind Injection Molding Innovations in 2026

In 2026, the injection molding process is set for a remarkable transformation. One key driving factor behind this change is the growing demand for lightweight materials. Industries are pushing for stronger, yet lighter alternatives, especially in automotive and aerospace. This shift enables manufacturers to create products that enhance fuel efficiency and performance. However, sourcing these materials remains a challenge. Balancing cost with innovation is essential, yet often elusive.

Another major trend is the integration of advanced technology. Robotics and automation are streamlining production processes, increasing precision and reducing waste. However, this transition isn't without its hurdles. Many manufacturers struggle with the initial investment and the need for skilled labor. The learning curve can be steep, causing delays and uncertainty. Meanwhile, leveraging data analytics is becoming crucial for optimizing efficiency. Yet, many companies may not fully understand how to analyze and apply this data effectively.

Sustainability is also a major driver. The push for eco-friendly practices influences the entire injection molding landscape. Businesses are exploring biodegradable materials and energy-efficient processes. Still, implementing these practices can prove difficult. The lack of standardization in materials can lead to inconsistency in quality. Companies must navigate these complexities as they strive to innovate while maintaining environmental responsibility.

2026 Top Trends in Injection Molding Process for Industry Innovations

This bar chart illustrates the top trends in the injection molding process for 2026, showcasing the importance level of each trend in driving industry innovations. Sustainability and material innovations rank the highest, highlighting the industry's focus on eco-friendly practices and advanced materials.

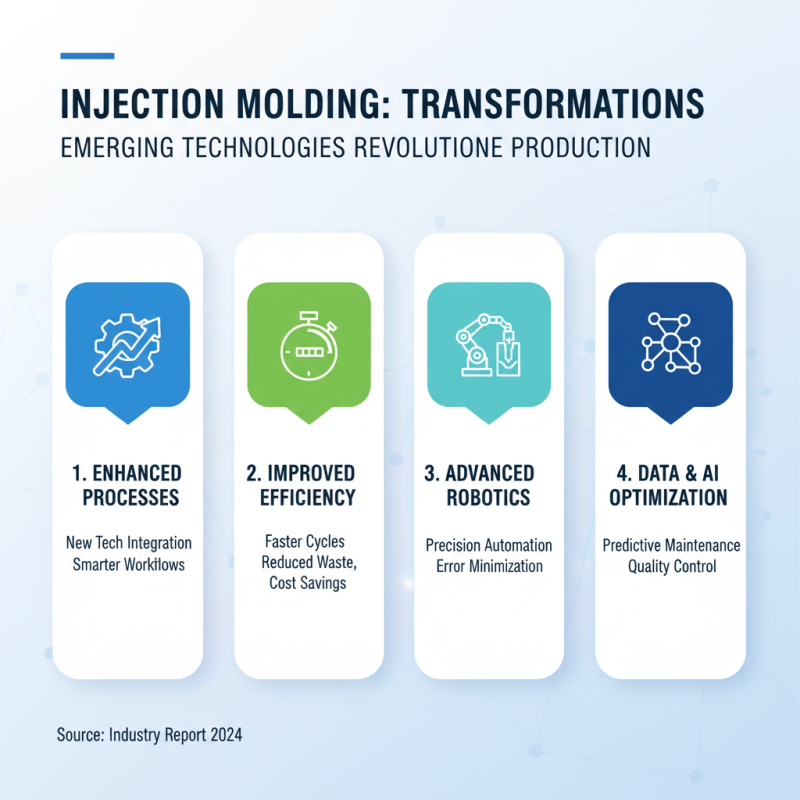

Emerging Technologies Transforming the Injection Molding Landscape

The injection molding landscape is undergoing significant transformations. Emerging technologies are at the forefront of these changes. They enhance processes and improve efficiency in production. Advanced robotics are streamlining workflows. With precision and speed, these machines minimize errors.

Additive manufacturing is also making waves. It enables the creation of complex geometries. This allows for innovative designs that were once impossible. The integration of AI in mold design is another exciting development. It predicts potential issues, saving time and resources. However, relying solely on technology poses its own challenges. Not all designs translate well from concept to reality.

Sustainability is a crucial aspect to consider. New materials that are eco-friendly are being explored. Biodegradable options are gaining traction. Yet, the balance between performance and sustainability remains delicate. Innovations should not sacrifice quality for eco-friendliness. As the industry evolves, there is much to reflect on. Embracing new technologies brings opportunities and responsibility.

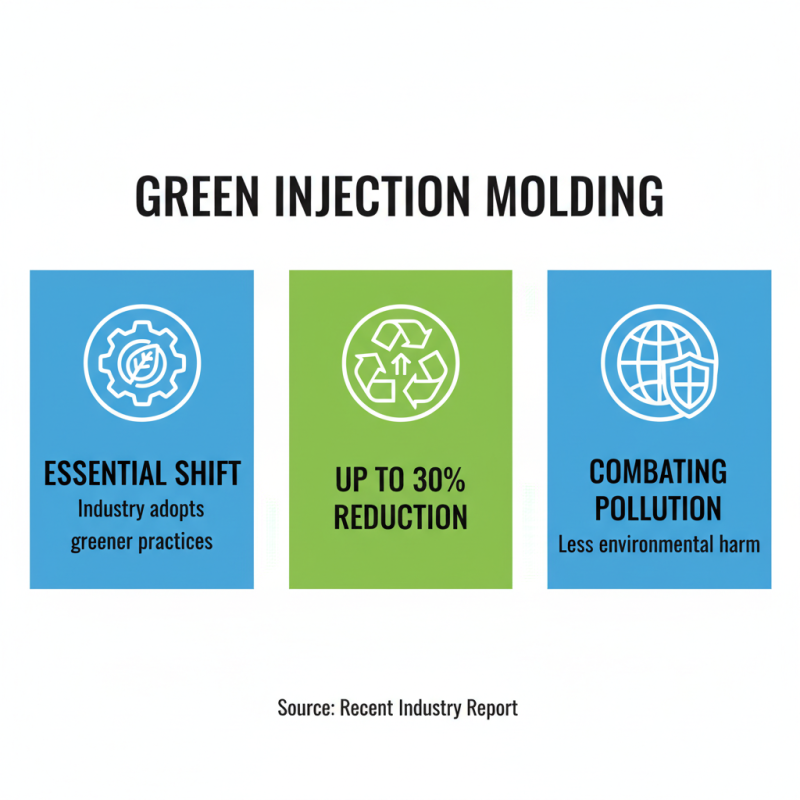

Sustainability Practices in Injection Molding for a Greener Future

Sustainability is becoming essential in injection molding. The industry is shifting towards greener practices. A recent report indicates that up to 30% of traditional materials used in this process contribute to environmental harm.

Innovations in bioplastics are making waves. Materials derived from renewable resources are gaining traction. Research shows using bioplastics can reduce carbon footprints by up to 50%. This shift could lead the industry into a new era of reduced emissions.

However, challenges remain. Not all bioplastics perform well under manufacturing conditions. The supply chain for sustainable materials is not fully established. Companies must navigate these hurdles while striving for a greener future. More effort is needed to create reliable and efficient systems to support this transition.

Enhancements in Material Science for Injection Molding Applications

The injection molding industry is evolving, especially in material science. Innovative polymers are emerging, enhancing flexibility and strength. According to a recent industry report, advanced thermoplastics can withstand temperatures up to 300°C. This opens new possibilities for various applications in automotive and aerospace sectors.

Recycled materials are gaining traction in injection molding. Over 30% of manufacturers are now using recycled resins. While this trend promotes sustainability, it often comes with challenges. The quality of recycled materials can vary. Contaminants and inconsistent properties sometimes lead to production delays.

Moreover, bio-based polymers are entering the market. These materials reduce dependence on fossil fuels. Studies show that they can lower production carbon footprints by up to 50%. However, scalability remains a concern. Many manufacturers hesitate to adopt these materials due to limited availability and higher costs. The balance between innovation and practical challenges continues to shape the future of injection molding.

Integrating Automation and AI in Injection Molding Processes

The integration of automation and AI in injection molding processes is reshaping the industry. According to recent market analyses, 45% of manufacturers are investing in AI technologies to streamline production. These technologies enhance efficiency and reduce downtime. Moreover, predictive maintenance powered by AI can cut maintenance costs by up to 30%.

However, transitioning to automation does bring challenges. Many companies report initial costs and employee retraining as significant obstacles. A study shows that 60% of teams lack the necessary skills to operate new automated systems effectively. Companies need to address this skills gap to ensure a smooth transition.

Tips: Start with small automation projects. Measure outcomes closely. Training workshops can help bridge the skills gap. Keep communication open with employees throughout the process. Embrace iterative improvements rather than expecting perfection from the start. Remember, the implementation of new technologies is an ongoing journey.

Related Posts

-

2026 Top Trends in Protomold Injection Molding Technology?

-

The Future of Injection Tooling in Sustainable Manufacturing Practices

-

Exploring the Future of Injection Molding in Canada: Innovations and Trends Driving the Industry

-

10 Essential Tips for Effective Rapid Injection Molding Techniques?

-

10 Best Plastic Injection Molding Machines for Quality Production?

-

The Best 10 Tips for Optimizing Injection Tooling Efficiency